引 言

从1957年Irwin [1]提出应力强度因子概念算起,断裂力学发展至今不过几十年时间.然而其发展异常迅速,是目前固体力学中最活跃的一个分支,并已被广泛地用来解决各种工程实际问题.其中,裂纹尖端应力强度因子是判断裂纹扩展和结构失效的重要标准.

对于某些受载情况下的无限宽板裂纹问题,目前已求得了裂纹前缘应力-应变场的解析解,最经典的方法是复变函数Westergaard应力函数方法[2],但是对于裂纹长度与板宽相比并不是很小的有限宽板,目前还很难得到理论上的精确解,只能通过一些近似简化、数值计算、实验测定得出近似解答.

对于有限宽板Ⅰ型裂纹,只有少数情况可以进行解析分析得出近似解[3],较早的研究成果可见文献[4-6],而用得比较多的近似方法之一是采用边界配置法,但是此方法是一种数值分析方法,不适于裂纹表面存在面力分布的情况.需要指出的是,所有这些近似解法都具有数学上的复杂性或较大的求解工作量.并且,这些解法都不能利用现有的无限大板裂纹体的解析结果,使之通过适当简化来求解工程上更为常见的有限宽板裂纹问题.

裂纹线场分析方法是断裂力学中裂纹弹塑性分析一种十分有效的方法,最早由Achenbach等[7]和Guo等[8]提出,本文作者Yi(易志坚)对该方法进行了进一步研究[9-11],提出了一种全新意义下的线场分析方法,使其从根本上放弃了小范围屈服条件[12-18].这一方法的基本思路是:求出塑性场在裂纹线附近的幂级数形式的通解,并将裂纹体弹性场的精确解在裂纹线附近按幂级数形式展开;将塑性场的通解与弹性场的精确解在裂纹线附近的弹塑性边界上匹配,从而完全放弃小范围屈服条件,求出裂纹线附近足够精确的不受屈服范围大小限制的弹塑性场.目前采用这一方法,已经解决了大量问题[19-25].这一方法还可用于裂纹面附近的裂纹弹塑性分析[26-28].

利用线场分析方法,还可以求解应力强度因子[29-30],这一方法简洁、有效且力学概念清晰,其思路如下:直接选用无限宽板裂纹问题应力场的解析解,然后求得应力分量在裂纹线上的形式;通过合理的修正,提出修正后的应力场在裂纹线应满足的条件,进而求得应力强度因子.

本文即采用应力强度因子线场分析求解方法,对裂纹面局部均布荷载下Ⅰ型裂纹有限宽板的应力强度因子进行解析求解.

1 裂纹面局部均布荷载下Ⅰ型裂纹有限宽板的应力强度因子求解

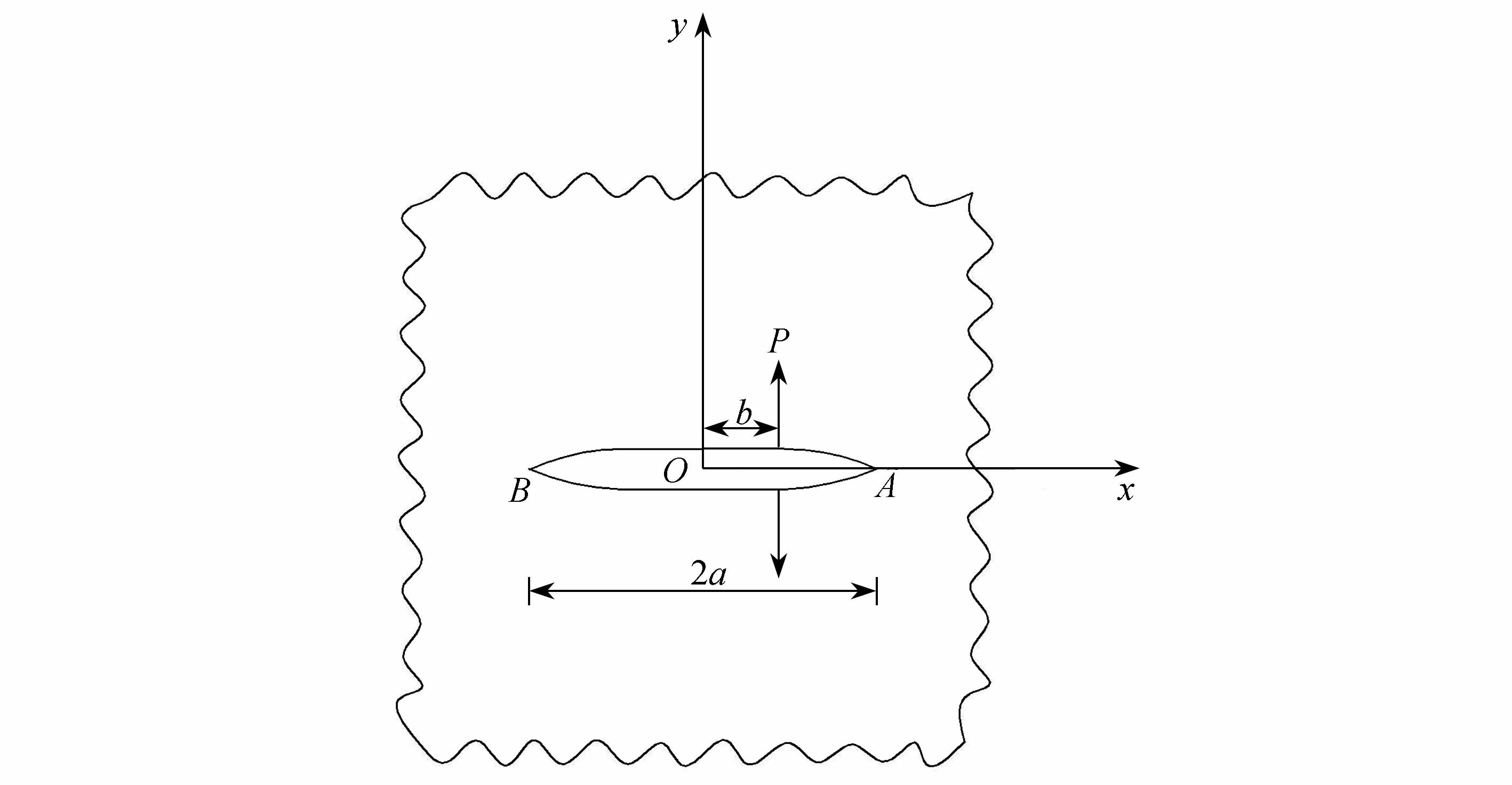

如图1所示宽度为2w、具有2a长度中心穿透 Ⅰ 型裂纹的有限宽板,其在裂纹面上c<|x|<a范围内局部受均布荷载σ作用,要求其裂纹尖端应力强度因子,根据应力强度因子线场分析求解方法,首先需要明确相应无限宽板(图2)在其裂纹线上的应力分量和应力强度因子.

图1 裂纹面局部均布荷载下Ⅰ型裂纹有限宽板 图2 裂纹面局部均布荷载下Ⅰ型裂纹无限宽板

Fig.1 A finite-width plate with a mode-Ⅰ center crack subjected to uniform stress on the crack surface near the crack tip Fig.2 An infinite-width plate with a mode-Ⅰ crack subjected to uniform stress on the crack surface near the crack tip

为了求解如图2所示无限宽板的应力强度因子,本文首先需要利用裂纹面上作用一对劈开力的穿透Ⅰ型裂纹(如图3所示)无限宽板的应力强度因子,然后通过叠加原理获得.

图3 裂纹面上作用一对劈开力的穿透Ⅰ型裂纹无限宽板

Fig.3 An infinite-width plate with a mode-I crack subjected to a pair of splitting forces on the crack surface

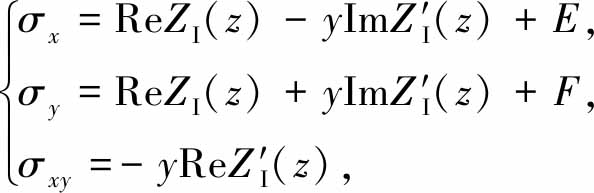

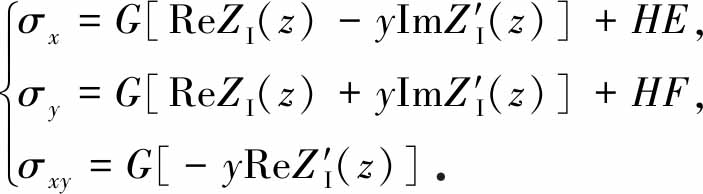

按照线弹性材料裂纹问题应力场的复变函数求解方法,对于Ⅰ型裂纹,若取任一复变解析函数ZI(z)为Westergaard应力函数,则应力表达式为[31-32]

(1)

其中,Re表示取函数实部,Im表示取函数虚部,E和F为应力分量的常数项.

此时,如果式(1)满足弹性理论的基本方程,即满足平衡微分方程和相容方程,并同时满足裂纹问题边界条件(包括裂纹面)时,则其为裂纹问题的精确解.但是,传统的断裂力学往往仅求解裂纹尖端附近的解,即著名的裂纹尖端应力强度因子场,它具有奇异性,其中的应力强度因子反映应力场奇异性的强弱程度.

通常,当知道一个特定问题的Westergaard应力函数ZI(z)后,应力强度因子为[31-32]

(2)

针对如图3所示具有穿透Ⅰ型裂纹的无限板,其在裂纹面上作用一对劈开力P时,其Westergaard应力函数为[31-32]

(3)

可以验证,上述解能满足问题的全部边界条件.

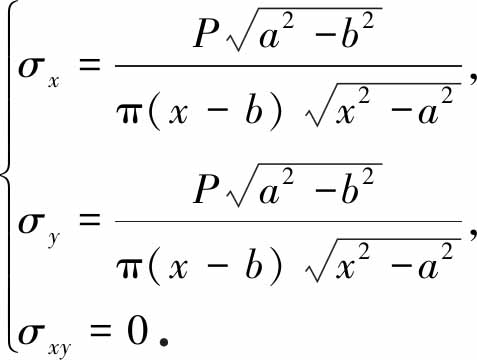

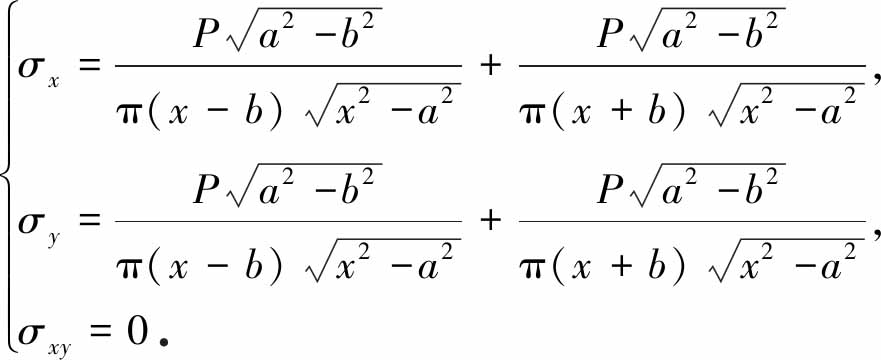

根据应力分量表达式(1),将z=x+iy代入上式,并令y=0,x>a即可得在裂纹线上的应力分量:

(4)

根据上述应力函数可得裂纹右端A和左端B的应力强度因子分别为

(5)

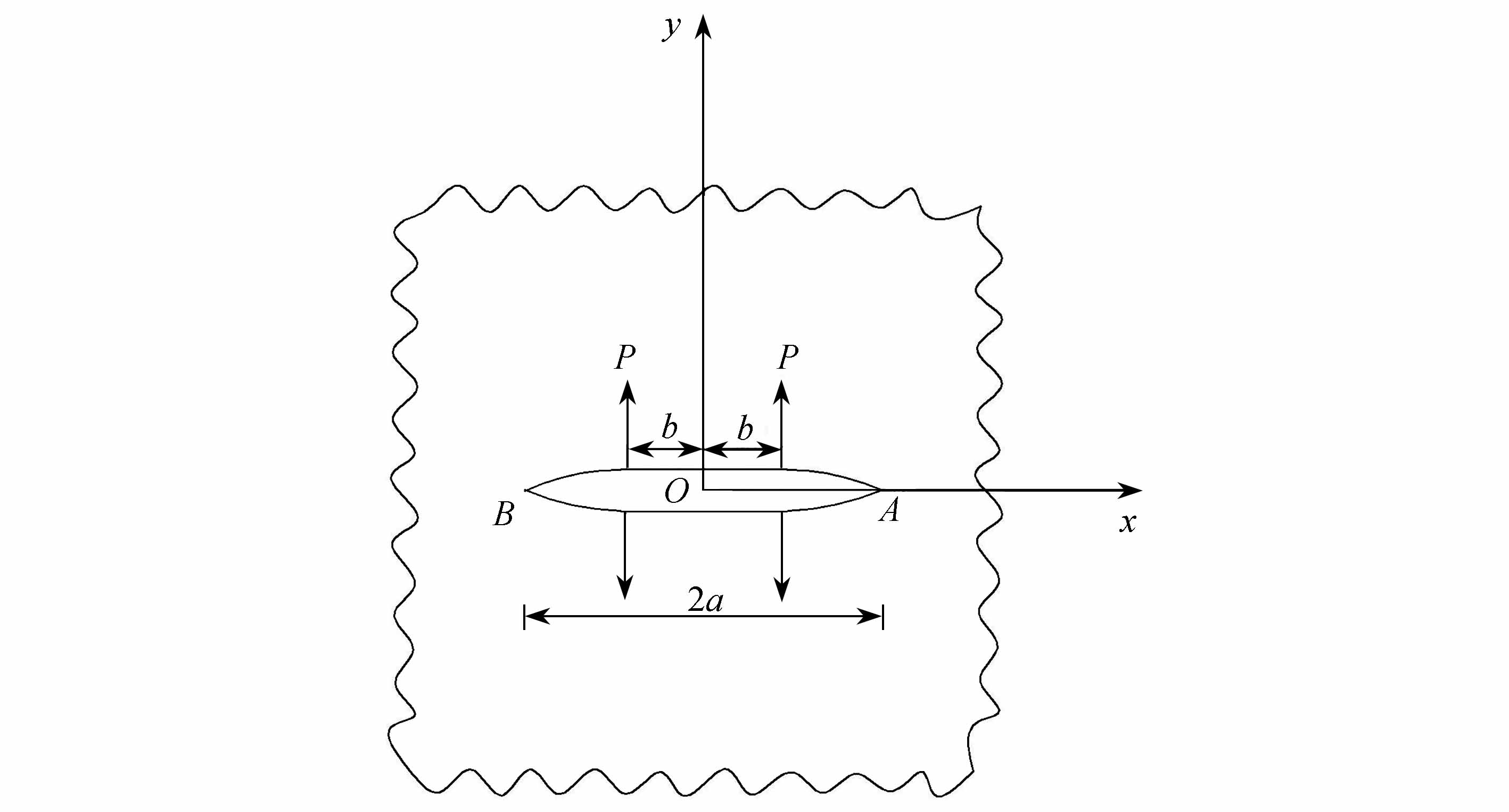

当裂纹面上对称于裂纹中心再作用一对劈开力P时,如图4所示,即具有穿透Ⅰ型裂纹的无限板,其左、右裂纹面上各作用一对劈开力P时,其裂纹线上的应力分量,即y=0,x>a时,可由式(4)根据叠加原理表示为

图4 裂纹左、右裂纹面上各作用一对相互对称劈开力的穿透Ⅰ型裂纹无限宽板

Fig.4 An infinite-width plate with a mode-I crack subjected to a pair of splitting forces on the left and right parts of the crack surface

(6)

而此时其应力强度因子可由式(5)叠加得

(7)

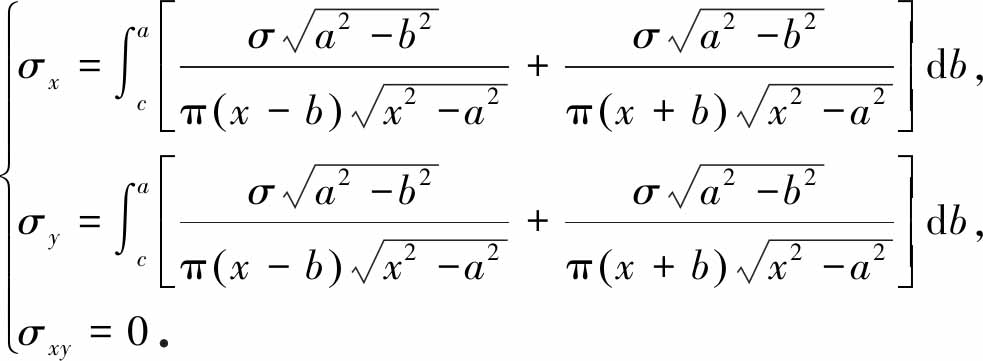

进一步地,根据叠加原理,通过对式(6)进行积分即可得如图2具有穿透Ⅰ型裂纹的无限宽板在裂纹线上的应力分量,即y=0,x>a时,应力分量为

(8)

而此时其应力强度因子可由式(7)积分得

(9)

至此,式(8)即为相应无限宽板(图2)在其裂纹线上的应力分量,而式(9)为其裂纹尖端应力强度因子.

下一步需要用式(8)来构造相应的有限宽板(图1)在其裂纹线上的应力分量,构造方法如下.

如前文所述,基于Westergaard函数表达的式(1)满足弹性理论的基本方程,即平衡微分方程和相容方程,且针对某一具体无限宽板问题,选取特定的Westergaard应力函数后,既能满足远场边界条件,又能满足裂纹面边界条件.故此时,式(1)即为这一具体问题的精确解.

而针对与该无限宽板问题相应的有限宽板问题,尽管该问题的应力场不清楚,但在有裂纹线附近却应与式(1)有类似的形式,可以通过常数G和H对式(1)进行修正的方式,得到其在裂纹线附近足够精确的解:

(10)

显然,式(10)依旧满足弹性理论的基本方程和裂纹面边界条件.原因如下:由于式(1)满足平衡微分方程和相容方程,而通过常数G和H对式(1)进行上述修正后,所得式(10)依旧满足平衡微分方程和相容方程;同时,由于式(1)满足裂纹面上边界条件,即除力作用点外,裂纹表面自由,而式(10)是通过将式(1)乘以系数G和H得到,故其同样满足裂纹面上的边界条件.因此,式(10)即为相应有限宽板在裂纹线附近的足够精确的应力分量.

针对如图2所示无限宽板,已得到其在裂纹线上的应力分量如式(8)所示.而针对与其相应的、如图1所示宽度为2w的有限宽板,有一长2a的中心裂纹,在裂纹面上局部受到均匀拉伸压力σ,由于该问题的复杂性,目前还没有得到既满足裂纹面边界条件,又满足板的自由边界的解.但是,可以通过对式(8)进行修正的方式,在裂纹线附近(y=0,x>a)近似有

(11a)

(11b)

σxy=0,

(11c)

式中G为与板宽2w及裂纹长度2a及荷载分布范围2c有关的系数.

显然式(11)仍满足裂纹面边界条件,那么只要在裂纹线上提出一个合理边界条件,则式(11)可被认为在裂纹线上近似成立.

裂纹线上条件可以这样提:假想裂纹线AN,BM将板截开分为上、下两部分,考虑上半部分,则AN,BM上的应力与外载平衡,由问题的对称性可得

2![]() σydx=2

σydx=2![]() σdx,

σdx,

(12)

即

(13)

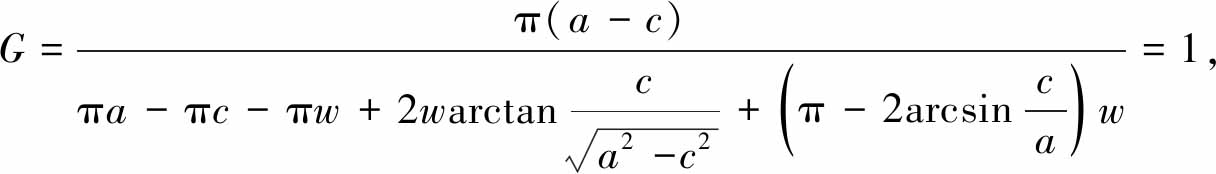

求解可得

(14)

其与c/a和a/w有关.将上式代入式(11b)即可得裂纹线上的σy,此解既满足裂纹面边界条件,又满足裂纹线边界条件,因而可以认为此解在裂纹线上足够精确.由所得σy即可得该问题的应力强度因子

(15)

此时,G为有限宽板应力强度因子对无限大板情形的修正系数,与c/a和a/w有关.式(15)即为本文得出的裂纹面局部均布荷载作用下的宽度为2w、具有2a长度的中心穿透Ⅰ型裂纹有限宽板应力强度因子.

2 求解结果分析

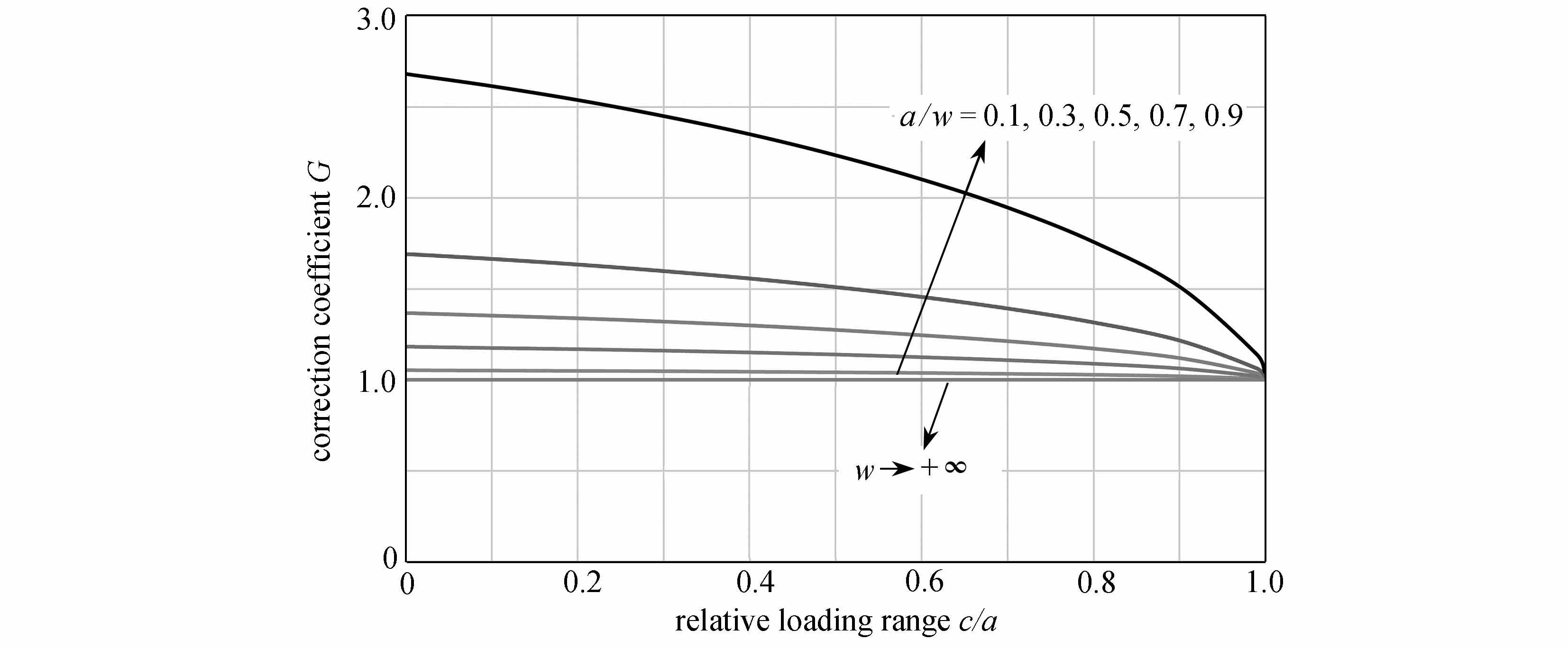

图5即为有限宽板应力强度因子对无限大板情形的修正系数G在不同裂纹相对长度a/w情况下与荷载分布相对长度c/a的关系曲线.

图5 有限宽板应力强度因子修正系数G与荷载分布相对长度c/a关系曲线

Fig.5 The relation curve between correction coefficient G of the stress intensity factor and relative loading range c/a of the finite-width plate

当w→+∞时,即板宽趋近于无穷大时,裂纹面局部均布荷载作用下的具有2a长度的中心穿透Ⅰ型裂纹有限宽板问题即变为如图2所示对应无限宽板问题.令w→+∞,则

(16)

则有

(17)

与对应无限宽板应力强度因子完全一致.此时,应力强度因子修正系数G在坐标系中是一条纵坐标为1的水平线.

3 结 论

本文采用应力强度因子的裂纹线求解方法,通过对相应无限宽裂纹板裂纹线上应力分量进行合理的修正,得出了裂纹面局部均布荷载作用下的Ⅰ型裂纹有限宽板在其裂纹线上的应力分量.并进一步根据其应力场在裂纹线上应满足的条件,得出了上述有限宽板对相应无限宽板的应力强度因子修正系数,进而求得了其应力强度因子.最后给出了所得修正系数在不同裂纹相对长度情况下与荷载分布相对长度的关系曲线.本文所得有限宽板应力强度因子求解结果,在当板宽趋于无限大时,与相应的无限宽裂纹板的解答一致.

[1] IRWIN G R.Analysis of stresses and strains near the end of crack traversing a plane[J].Journal of Applied Mechanics-Transactions of the ASME,1957,24:361-364.

[2] WESTERGAARD H M.Bearing pressure and cracks[J].The Journal of Applied Mechanics,1939,A61:49-53.

[3] MUSKHELISHIVILI N I.Some Basic Problems of the Mathematical Theory of Elasticity[M].Beijing:Science Press,1958:374-377.

[4] PARIS P C,SIH G C.Stress Analysis of Cracks,Fracture Toughness Testing and Its Applications[M].Philadelphia:ASTM,1965:30-70.

[5] SIH G C,LIEBOWITZ H.Mathematical Fundamentals,in Fracture:an Advanced Treatise[M].New York:Academic Press,1968:68-190.

[6] RICE J R.Mathematical Analysis in the Mathematics of Fracture,in Fracture:an Advanced Treatise[M].New York:Academic Press,1968:191-371.

[7] ACHENBACH J D,LI Z L.Plane stress crack line fields for crack growth in an elastic-perfectly plastic material[J].Engineering Fracture Mechanics,1984,20(3):534-544.

[8] GUO Q X,LI K R.Plastic deformation ahead of a plane stress tensile crack growth in an elastic-perfectly plastic solid[J].Engineering Fracture Mechanics,1987,28(2):139-146.

[9] YI Z J.The near crack line solution for plane stress tensile crack growth in an elastic-perfectly plastic material[J].Engineering Fracture Mechanics,1992,42(1):169-176.

[10] YI Z J.The more precise crack line analyses for antiplane quasistatically propagating crack[J].International Journal of Fracture,1992,55(1):9-12.

[11] YI Z J.The new and analytical solutions for mode Ⅲ cracks in an elastic-perfectly plastic material[J].Engineering Fracture Mechanics,1992,42(5):833-840.

[12] YI Z J.The most recent solutions of near crack line fields for mode Ⅲ cracks[J].Engineering Fracture Mechanics,1994,47(1):147-155.

[13] YI Z J,WANG S J,WU H L.Precise elastic-plastic analysis of crack line field for mode Ⅱ plane strain crack[J].International Journal of Fracture,1996,80(4):353-363.

[14] YI Z J,WANG S J,WANG X J.Precise solutions of elastic-plastic crack line fields for cracked plate loaded by antiplane point forces[J].Engineering Fracture Mechanics,1997,57(1):75-83.

[15] 易志坚.Ⅰ型平面应力有限宽裂纹板弹塑性分析[J].西南交通大学学报,1998,33(1):82-87.(YI Zhijian.Elastic-plastic analysis of mode Ⅰ cracked plate with finite dimensions under plane stress conditions[J].Journal of Southwest Jiaotong Uniersity,1998,33(1):82-87.(in Chinese))

[16] 易志坚,严波.Ⅰ型平面应力裂纹弹塑性场在裂纹线附近匹配方程的一般形式[J].应用数学和力学,2001,22(10):1058-1066.(YI Zhijian,YAN Bo.General form of matching equation of elastic-plastic field near crack line for mode Ⅰ crack under plane stress condition[J].Applied Mathematics and Mechanics,2001,22(10):1058-1066.(in Chinese))

[17] ZHOU X P,WANG J H,HUANG Y B.Near crack line elastic-plastic analysis for an infinite plate loaded by a pair of point shear forces[J].Journal of Shanghai Jiaotong University(Science),2003,E8(2):115-117.

[18] WANG J H,ZHOU X P.Near crack line elastic-plastic analysis for a infinite plate loaded by two pairs of point tensile forces[J].Mechanics Research Communications,2004,31(4):415-420.

[19] 王成,吴承平.偏心裂纹板在裂纹面受两对反平面点力的弹塑性解析解[J].应用数学和力学,2003,24(7):691-698.(WANG Cheng,WU Chengping.Elastic-plastic analytical solutions for an eccentric crack loaded by two pairs of anti-plane point forces[J].Applied Mathematics and Mechanics,2003,24(7):691-698.(in Chinese))

[20] 易志坚,赵朝华,杨庆国,等.Ⅲ型裂纹弹塑性场在裂纹线附近匹配方程的一般形式[J].应用数学和力学,2009,30(5):515-524.(YI Zhijian,ZHAO Chaohua,YANG Qingguo,et al.General forms of elastic-plastic matching equations for mode-Ⅲ cracks near the crack line[J].Applied Mathematics and Mechanics,2009,30(5):515-524.(in Chinese))

[21] YI Z J.Revisiting the Hult-Mcclintock closed-form solution for mode Ⅲ cracks[J].Journal of Mechanics of Materials and Structures,2010,5(6):1023-1035.

[22] GUO J H,LU Z X,FENG X.The fracture behavior of multiple cracks emanating from a circular hole in piezoelectric materials[J].Acta Mechanica,2010,215(1):119-134.

[23] GUO J H,LU Z X.Line field analysis and complex variable method for solving elastic-plastic fields around an anti-plane elliptic hole[J].Science China:Physics,Mechanics and Astronomy,2011,54(8):1495-1501.

[24] DENG J L,YANG P,DONG Q,et al.Elasto-plastic fracture analysis of finite-width cracked stiffened plate[J].Applied Mechanics &Materials,2014,496/500:1052-1057.

[25] LI Y,HUANG F,WANG M,et al.Near crack line elastic-plastic field for mode Ⅰ cracks under plane stress condition in rectangular coordinates[J].Advances in Materials Science and Engineering,2020(3):1-10.

[26] 易志坚,谷建义,何小兵,等.反平面裂纹在裂纹自由表面附近的弹塑性分析[J].应用数学和力学,2010,31(7):853-859.(YI Zhijian,GU Jianyi,HE Xiaobing,et al.Elastic-plastic analysis of an antiplane crack near the crack surface region[J].Applied Mathematics and Mechanics,2010,31(7):853-859.(in Chinese))

[27] HUANG F,YI Z J,GU J Y,et al.Elastic-plastic analysis near the crack surface region on a mode Ⅲ crack under a pair of point forces[J].AIP Advances,2016,6(6):065113.

[28] HUANG F,YI Z J,YANG Q G,et al.Elastic-plastic analysis of the crack surface vicinity under a pair of anti-plane forces applied at an arbitrary point on the crack surface[J].AIP Advances,2018,8(10):105033.

[29] 易志坚.求解应力强度因子的一种新方法[J].重庆交通大学学报,1991,10(3):37-41.(YI Zhijian.A new method of determining the stress intensity factors[J].Journal of Chongqing Jiaotong University,1991,10(3):37-41.(in Chinese))

[30] WANG Q Z.The crack-line stress field method for analysing SIFS of strips-illustrated with an eccentrically cracked tension strip[J].International Journal of Fracture,1993,59(2):R39-R43.

[31] GDOUTOS E E.Fracture Mechanics:an Introduction[M].Netherlands:Springer,2005.

[32] ANDERSON T L.Fracture Mechanics:Fundamentals and Applications[M].CRC Press,2015.