Non-Probabilistic Structural Reliability Analysis Integrating the PSO and the Kriging Model

-

摘要:

针对复杂结构可靠性分析中面临的隐式功能函数和小样本问题,提出了一种粒子群优化和Kriging模型相结合的结构非概率可靠性分析方法。采用多维椭球描述结构不确定参数,运用粒子群优化对模型相关参数进行求解,并构建隐式功能函数的Kriging模型进行可靠性分析。三个算例结果表明所提方法有效可行,精度和效率均优于基于Kriging模型的非概率可靠性分析方法。

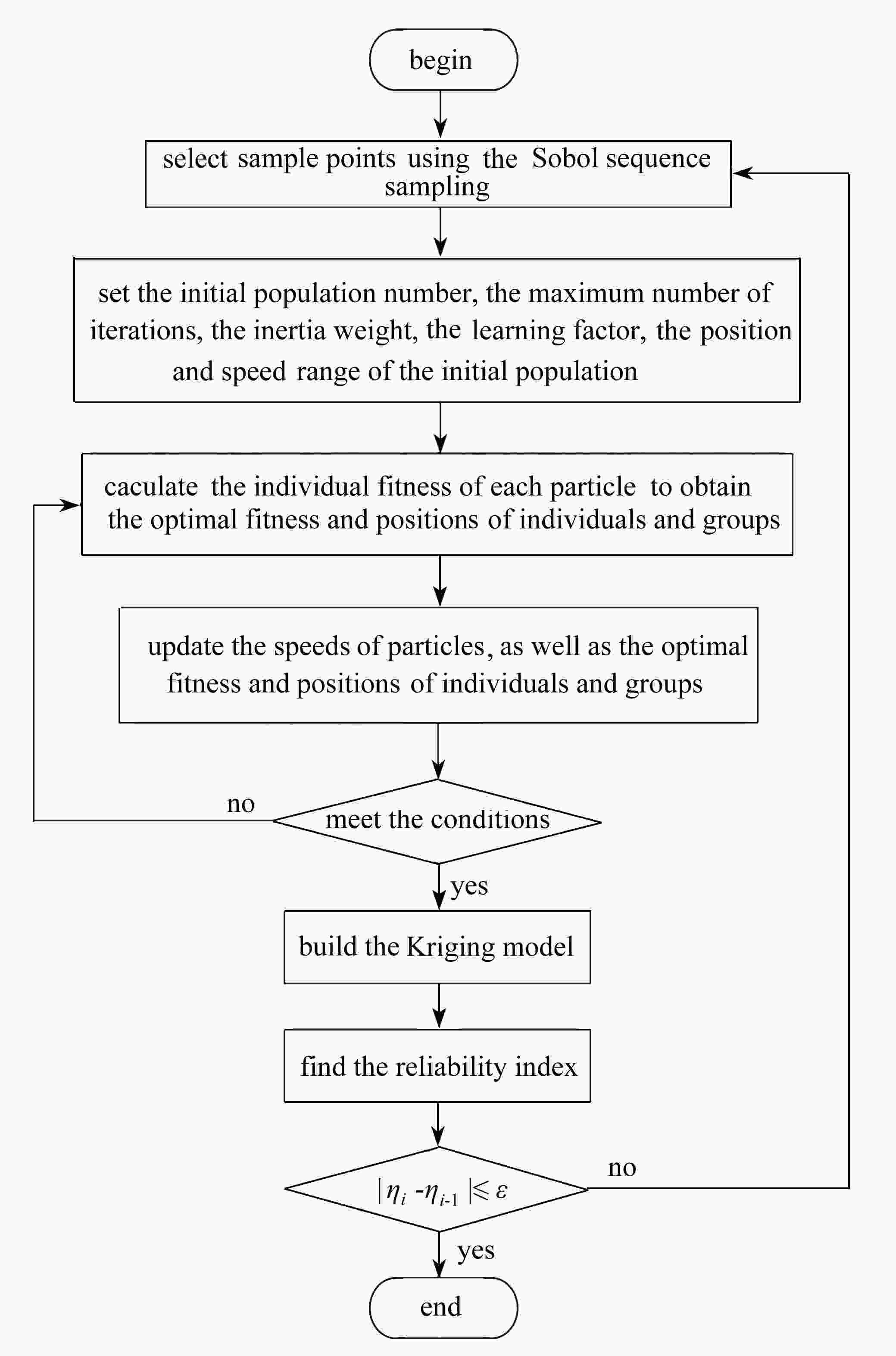

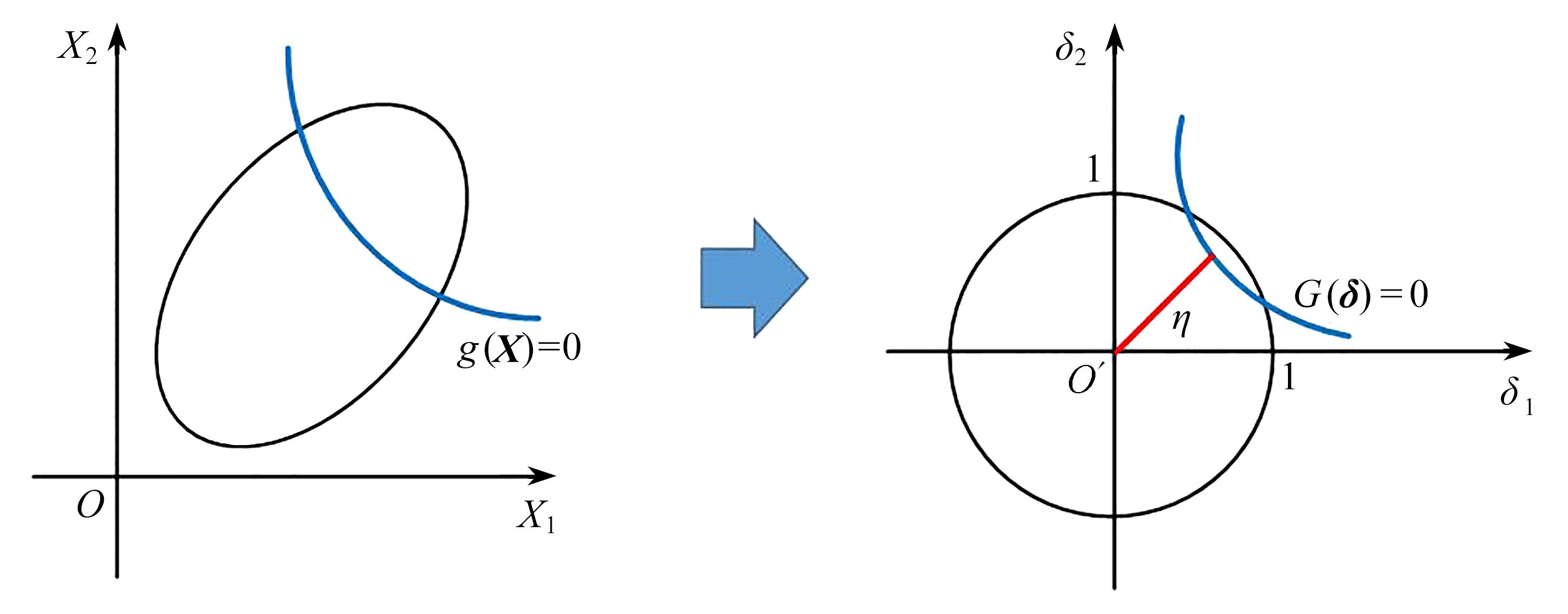

Abstract:In view of the problems with implicit performance functions and limited experimental data in the reliability analysis of complex structures, a non-probabilistic reliability method combining the particle swarm optimization (PSO) with the Kriging model was presented. A multidimensional ellipsoid was first used to characterize the uncertain parameters of structures. The Kriging model was then constructed for the implicit performance function, wherein its optimal related parameters was determined through the PSO. Based on the proposed model the reliability analysis was explicitly conducted. The results of 3 numerical examples show that, the proposed method is of effectiveness and feasibility, and has higher accuracy and efficiency than those based on the traditional Kriging model.

-

表 1 相关系数为0.2的迭代过程

Table 1. The iterative process for a correlation coefficient of 0.2

iteration step design point reliability index 0 (−2.4442, 4.2332) 4.8882 1 (−1.8607, 4.1064) 4.5083 2 (−1.8641, 4.1039) 4.5074 reference value (−1.8692, 4.1017) 4.5075 表 2 不同相关系数的可靠性指标(算例1)

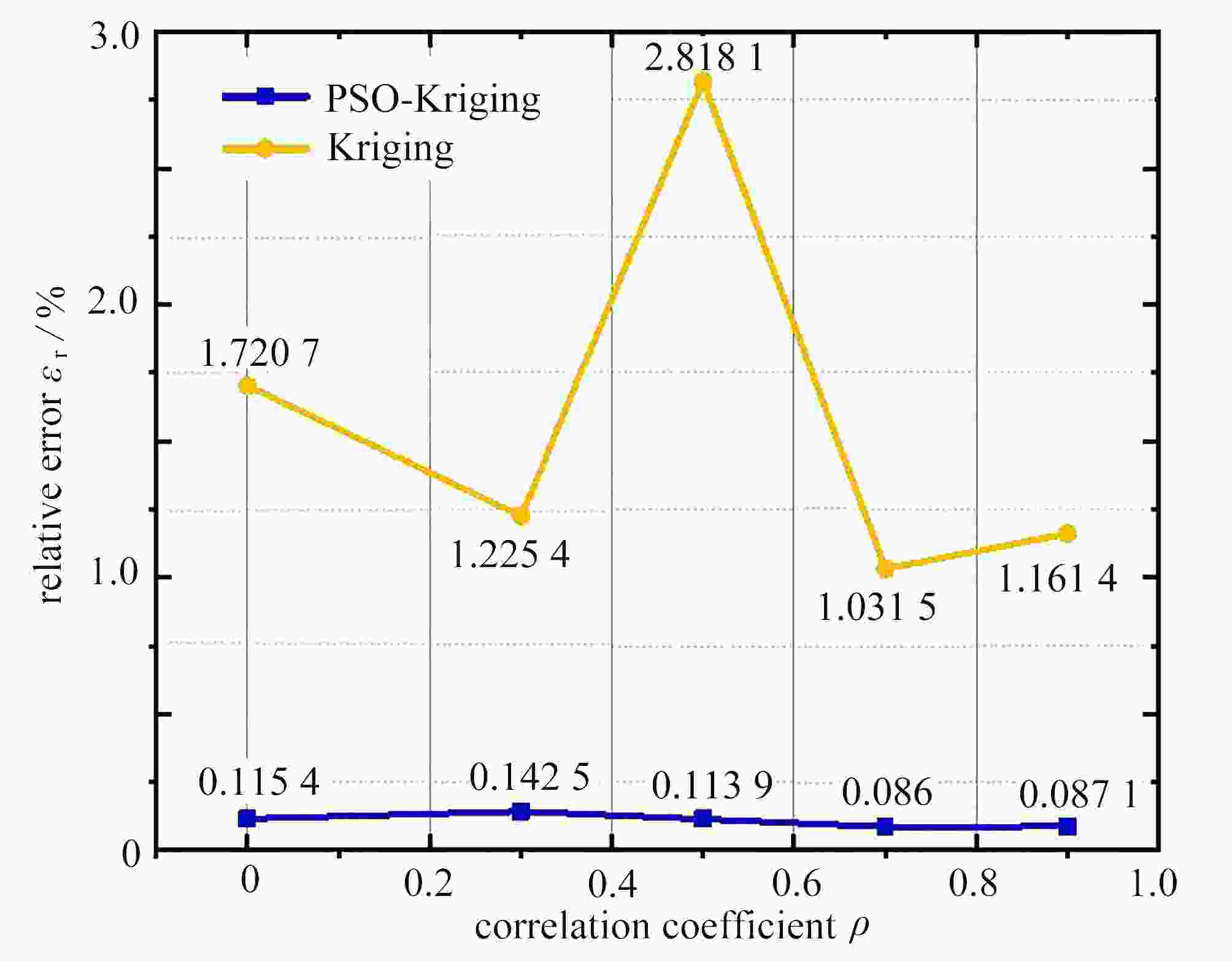

Table 2. Reliability indexes for different correlation coefficients (example 1)

correlation coefficient PSO-Kriging iterations CPU time Kriging iterations CPU time reference value 0 4.1704 2 0.45703 s 4.1653 5 1.00112 s 4.1701 0.2 4.5073 2 0.38524 s 4.5002 6 1.20133 s 4.5075 0.5 5.2134 3 0.68554 s 5.2039 5 1.01367 s 5.2138 0.7 5.9237 3 0.88563 s 5.9355 7 1.40156 s 5.9235 0.9 7.0337 2 0.57889 s 7.0302 6 1.16778 s 7.0339 表 3 相关系数为0.9的迭代过程

Table 3. The iterative process for a correlation coefficient of 0.9

iteration step design point reliability index 0 (0.0662, 0.0265, 0.0088, 0.00650.4059) 0.4123 1 (−0.0031, −0.0004, 0.0146, 0.0141, 0.3458) 0.3464 2 (−0.0040, −0.0005, 0.0124, 0.0176, 0.3415) 0.3422 3 (−0.0044, −0.0007, 0.00132, 0.0179, 0.3441) 0.3448 4 (−0.0042, −0.0007, 0.0134, 0.0181, 0.3439) 0.3447 reference value (−0.0058, −0.0015, 0.0146, 0.0155, 0.3437) 0.3444 表 4 不同相关系数的可靠性指标(算例2)

Table 4. Reliability indexes for different correlation coefficients (example 2)

correlation coefficient PSO-Kriging iterations CPU time Kriging iterations CPU time reference value 0 0.3469 4 16.15572 s 0.3406 7 27.16953 s 0.3465 0.3 0.3504 5 20.19465 s 0.3466 9 34.93226 s 0.3509 0.5 0.3517 4 17.23898 s 0.3612 7 26.35562 s 0.3513 0.7 0.3487 5 21.56773 s 0.3454 8 31.05089 s 0.3490 0.9 0.3447 4 18.06577 s 0.3404 7 28.09947 s 0.3444 表 5 MCS求解的95%置信区间(算例2)

Table 5. The 95% confidence intervals of MCS solutions (example 2)

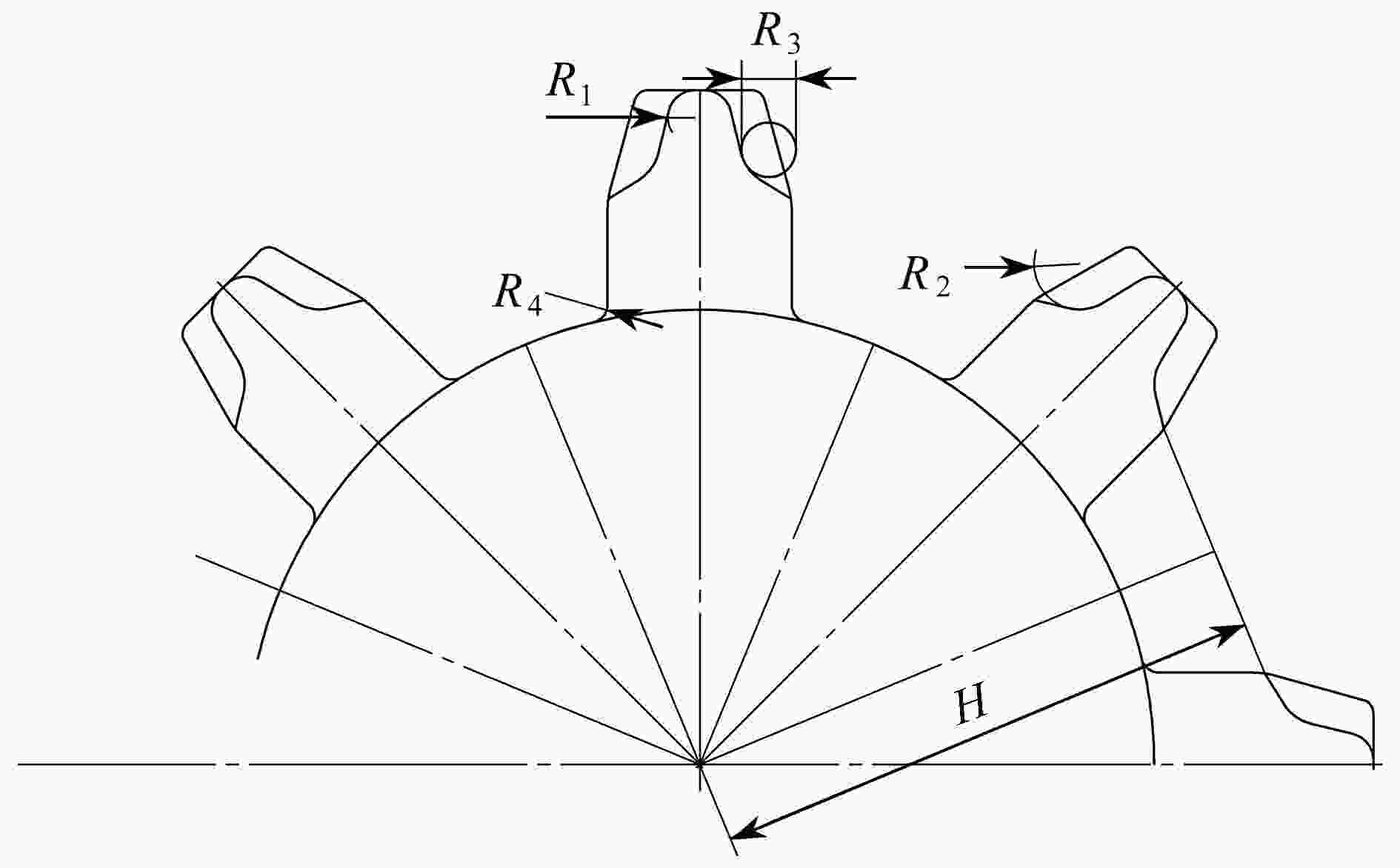

MCS value mean value deviation lower bound upper bound 0.3465 0.3469 0.0029 0.3463 0.3475 0.3509 0.3506 0.0029 0.3500 0.3511 0.3513 0.3511 0.0030 0.3505 0.3517 0.3490 0.3491 0.0030 0.3485 0.3497 0.3444 0.3448 0.0031 0.3442 0.3454 表 6 不确定变量的分布参数

Table 6. The distribution parameters of uncertain variables

uncertain variable mean value radius $ {A_1} $/mm2 700 70 $ {A_2} $/mm2 6200 620 $ {A_3} $/mm2 5300 530 $ {A_4} $/mm2 8800 880 $ L $/mm 15000 1500 表 7 相关系数为0的迭代过程

Table 7. The iterative process for a correlation coefficient of 0

iteration step design point reliability index 0 (−0.0083, −0.4266, −0.3646, −0.0519, 0.8256) 0.9997 1 (−0.0109, −0.5652, −0.4831, −0.0587, 0.9338) 1.1952 2 (−0.0100, −0.5201, −0.4446, −0.0540, 0.8593) 1.0997 3 (−0.0089, −0.4827, −0.4126, −0.0478, 0.7875) 1.0870 4 (−0.0084, −0.5107, −0.4222, −0.0509, 0.8504) 1.0793 5 (−0.0105, −0.5065, −0.4289, −0.0465, 0.8372) 1.0694 6 (−0.0094, 0.5032, −0.4301, −0.0431, 0.8356) 1.0669 reference value (−0.0092, −0.5043, −0.4280, −0.0484, 0.8340) 1.0656 表 8 不同相关系数的可靠性指标(算例3)

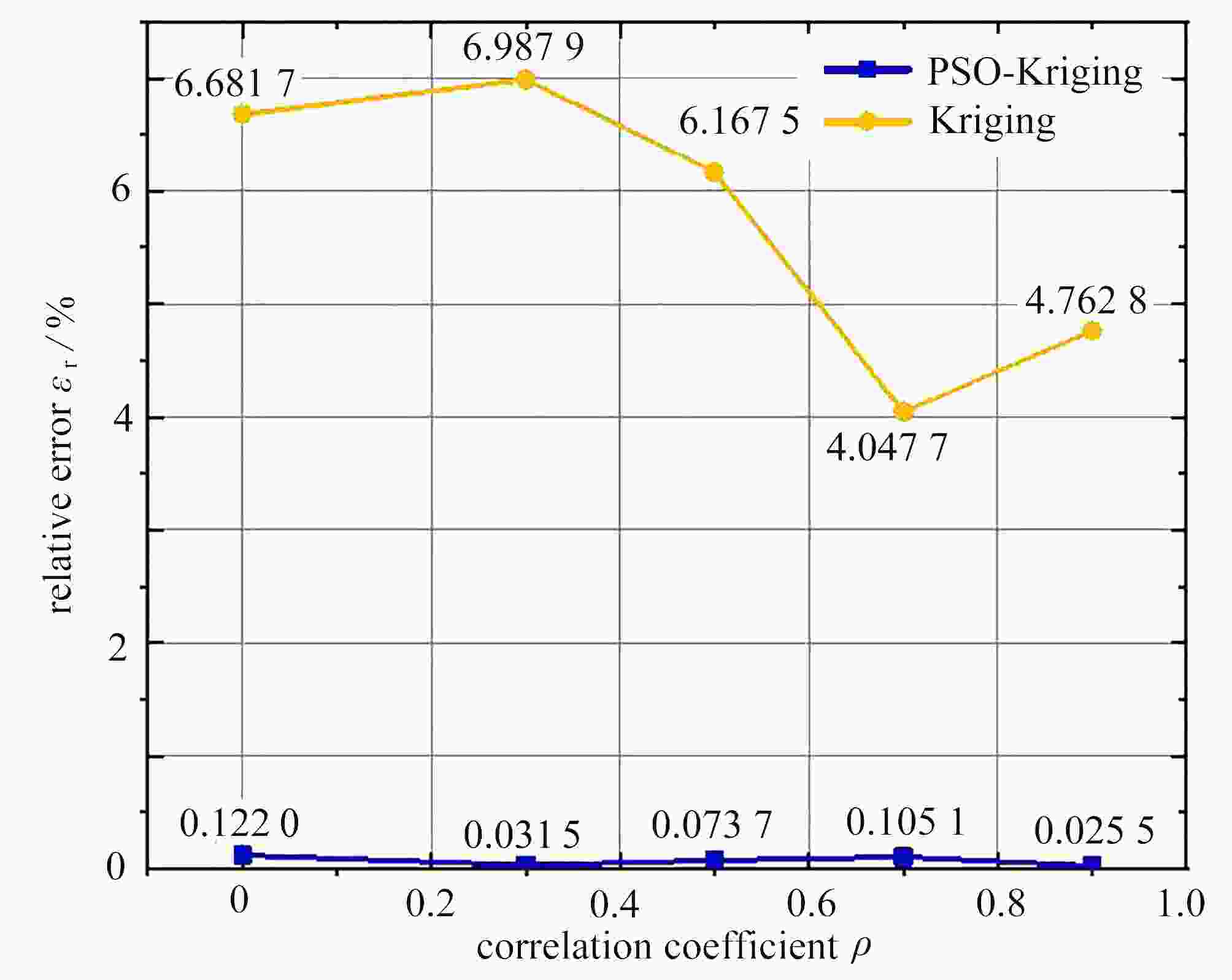

Table 8. Reliability indexes for different correlation coefficients (example 3)

correlation coefficient PSO-Kriging iterations CPU time Kriging iterations CPU time reference value 0 1.0669 6 27.02193 s 0.9944 9 37.73403 s 1.0656 0.3 1.2683 7 31.52558 s 1.1793 10 41.92578 s 1.2679 0.5 1.4906 6 28.02193 s 1.3997 10 40.44356 s 1.4917 0.7 1.9043 6 26.02193 s 1.8253 9 38.37882 s 1.9023 0.9 3.1439 7 31.52558 s 2.9934 11 46.11937 s 3.1431 表 9 MCS求解的95%置信区间(算例3)

Table 9. The 95% confidence intervals of MCS solutions (example 3)

MCS value mean value deviation lower bound upper bound 1.0656 1.0659 0.0029 1.0653 1.0665 1.2679 1.2672 0.0028 1.2667 1.2679 1.4917 1.4919 0.0025 1.4914 1.4924 1.9023 1.9023 0.0028 1.9017 1.9029 3.1431 3.1430 0.0029 3.1424 3.1435 -

[1] BEN-HAIM Y. A non-probabilistic concept of reliability[J]. Structural Safety, 1994, 14(4): 227-245. doi: 10.1016/0167-4730(94)90013-2 [2] ELISHAKOFF I, BEN-HAIM Y. Discussion on: a non-probabilistic concept of reliability[J]. Structural Safety, 1995, 17(3): 195-199. doi: 10.1016/0167-4730(95)00010-2 [3] 郭书祥, 吕震宙, 冯元生. 基于区间分析的结构非概率可靠性模型[J]. 计算力学学报, 2001, 18(1): 56-60GUO Shuxiang, LÜ Zhengzhou, FENG Yuansheng. A non-probabilistic model of structural reliability based on interval analysis[J]. Chinese Journal of Computational Mechanics, 2001, 18(1): 56-60.(in Chinese) [4] JIANG T, CHEN J J, XU Y L. A semi-analytic method for calculating non-probabilistic reliability index based on interval models[J]. Applied Mathematical Modelling, 2007, 31(7): 1362-1370. doi: 10.1016/j.apm.2006.02.013 [5] 曹鸿钧, 段宝岩. 基于凸集合模型的非概率可靠性研究[J]. 计算力学学报, 2005, 22(5): 546-549, 578CAO Hongjun, DUAN Baoyan. An approach on the non-probabilistic reliability of structures based on uncertainty convex models[J]. Chinese Journal of Computational Mechanics, 2005, 22(5): 546-549, 578.(in Chinese) [6] JIANG C, LU G Y, HAN X, et al. Some important issues on first-order reliability analysis with non-probabilistic convex models[J]. ASME Journal of Mechanical Design, 2014, 136(3): 034501. doi: 10.1115/1.4026261 [7] MENG Z, HU H, ZHOU H L. Super parametric convex model and its application for non-probabilistic reliability-based design optimization[J]. Applied Mathematical Modelling, 2018, 55: 354-370. doi: 10.1016/j.apm.2017.11.001 [8] MENG Z, ZHANG Z, ZHOU H L. A novel experimental data-driven exponential convex model for reliability assessment with uncertain-but-bounded parameters[J]. Applied Mathematical Modelling, 2020, 77(1): 773-787. [9] WANG X, QIU Z P, ELISHAKOFF I. Non-probabilistic set-theoretic model for structural safety measure[J]. Acta Mechanica, 2008, 198: 51-64. doi: 10.1007/s00707-007-0518-9 [10] JIANG C, BI R G, LU G Y, et al. Structural reliability analysis using non-probabilistic convex model[J]. Computer Methods in Applied Mechanics and Engineering, 2013, 254: 83-98. doi: 10.1016/j.cma.2012.10.020 [11] 陈江义, 文尉超, 王迎佳. 基于响应面方法的结构非概率可靠性分析[J]. 郑州大学学报(工学版), 2015, 36(5): 121-124CHEN Jiangyi, WEN Weichao, WANG Yingjia. Analysis of structural non-probabilistic reliability based on response surface method[J]. Journal of Zhengzhou University (Engineering Science) , 2015, 36(5): 121-124.(in Chinese) [12] BAI Y C, HAN X, JIANG C, et al. A response-surface-based structural reliability analysis method by using non-probability convex model[J]. Applied Mathematical Modelling, 2014, 38(15/16): 3834-3847. [13] 马超, 吕震宙. 隐式极限状态方程的非概率可靠性分析[J]. 机械强度, 2009, 31(1): 45-50 doi: 10.3321/j.issn:1001-9669.2009.01.010MA Chao, LÜ Zhengzhou. Non-probablistic reliability analysis method for implicit limit state function[J]. Journal of Mechanical Strength, 2009, 31(1): 45-50.(in Chinese) doi: 10.3321/j.issn:1001-9669.2009.01.010 [14] 潘林锋, 周昌玉, 陈士诚. 基于Kriging模型的非概率可靠度计算[J]. 应用力学学报, 2010, 27(4): 791-794PAN Linfeng, ZHOU Changyu, CHEN Shicheng. Non-probability reliability calculation based on Kriging model[J]. Chinese Journal of Applied Mechanics, 2010, 27(4): 791-794.(in Chinese) [15] 郑严. 基于智能算法的结构可靠性分析及优化设计研究[D]. 博士学位论文. 成都: 西南交通大学, 2012.ZHEN Yan. Research on structural reliability analysis and optimization based on intelligence algorithm[D]. PhD Thesis. Chengdu: Southwest Jiaotong University, 2012.(in Chinese) [16] JIANG C, HAN X, LU G Y, et al. Correlation analysis of non-probabilistic convex model and corresponding structural reliability technique[J]. Computer Methods in Applied Mechanics & Engineering, 2011, 200(33/36): 2528-2546. [17] 屈力刚, 刘洪侠, 李铭, 等. 基于Sobol序列采样点分布策略的研究与应用[J]. 锻压装备与制造技术, 2019, 54(6): 101-105 doi: 10.16316/j.issn.1672-0121.2019.06.030QU Ligang, LIU Hongxia, LI Ming, et al. Research and application of sampling point distribution strategy based on Sobol sequence[J]. China Metalforming Equipment & Manufacturing Technology, 2019, 54(6): 101-105.(in Chinese) doi: 10.16316/j.issn.1672-0121.2019.06.030 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号