Reduced-Scale Experiment Study on the Protective Mechanism of Foam Coating Against Underwater Explosion Bubble Jet

-

摘要:

水下爆炸会对水中结构物造成严重威胁。柔性覆盖层或夹层板能够降低水中结构物水下爆炸冲击响应,因此成为研究的热点。以往的研究多集中于覆盖层对冲击波的防护机理,适用于较远距离的水下爆炸情况。近距离水下爆炸除了冲击波外,爆炸气泡溃灭时产生的朝向结构物的高速水射流更为致命。该文针对这种情况,基于量纲原理,推导缩比相似关系,通过缩比模型水下爆炸试验发现了覆盖层表面空化微气泡群对爆炸气泡形成高速水射流过程产生干扰,提出了泡沫覆盖层钢板水下爆炸气泡射流防护机理。

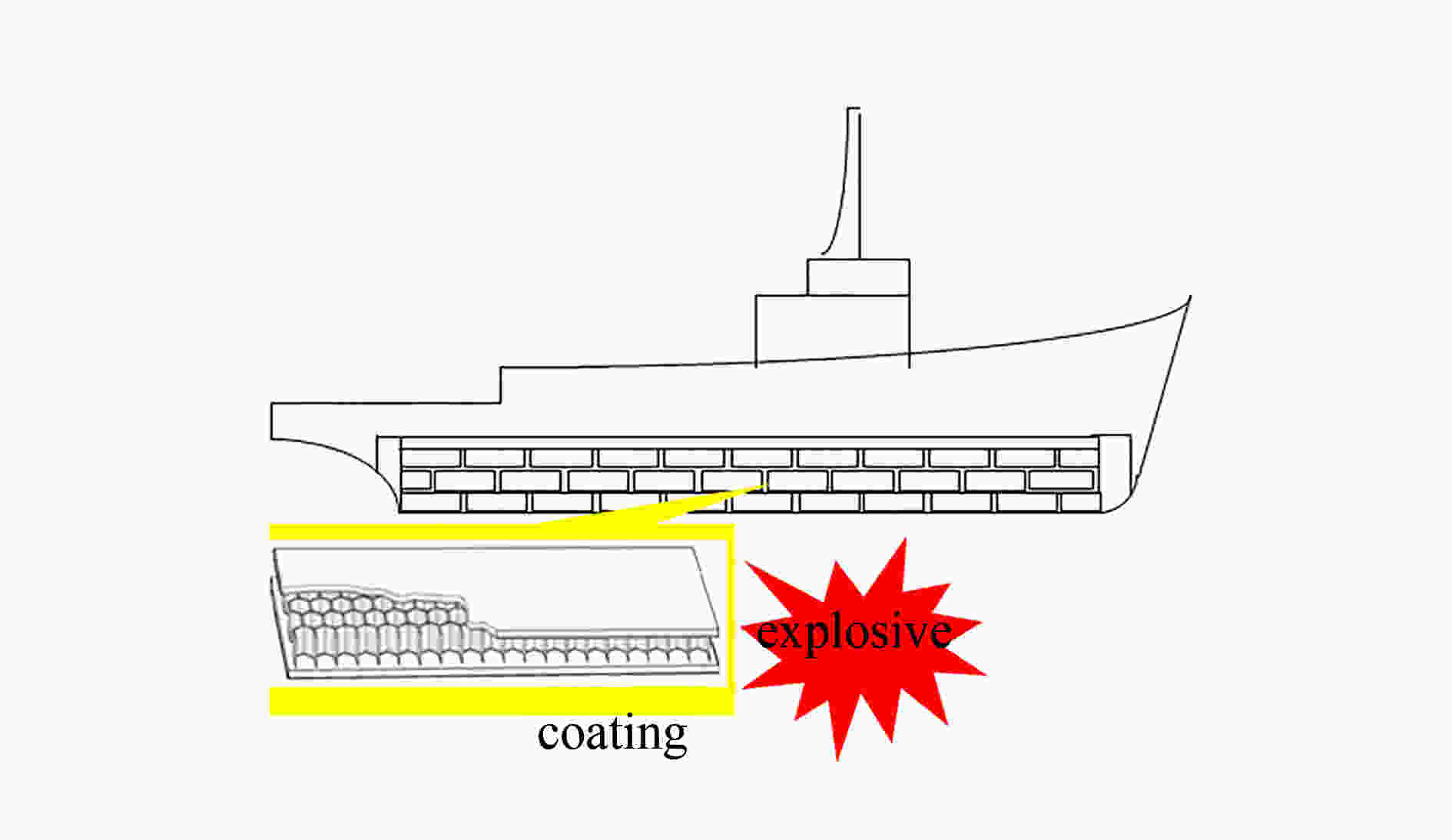

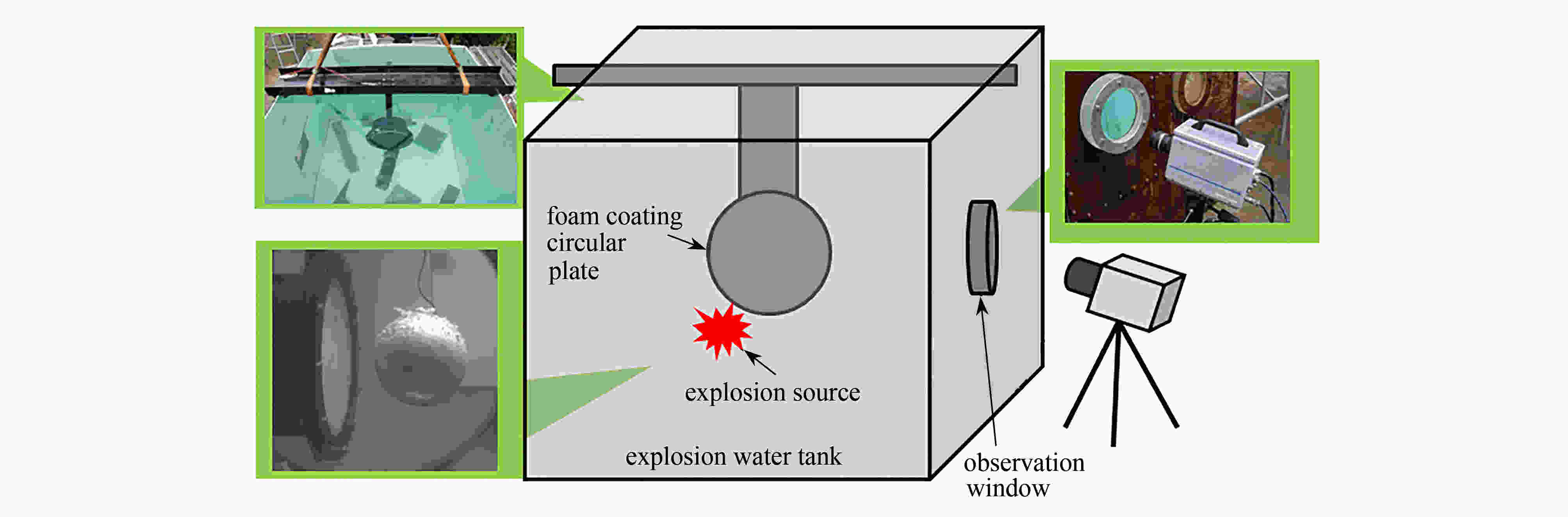

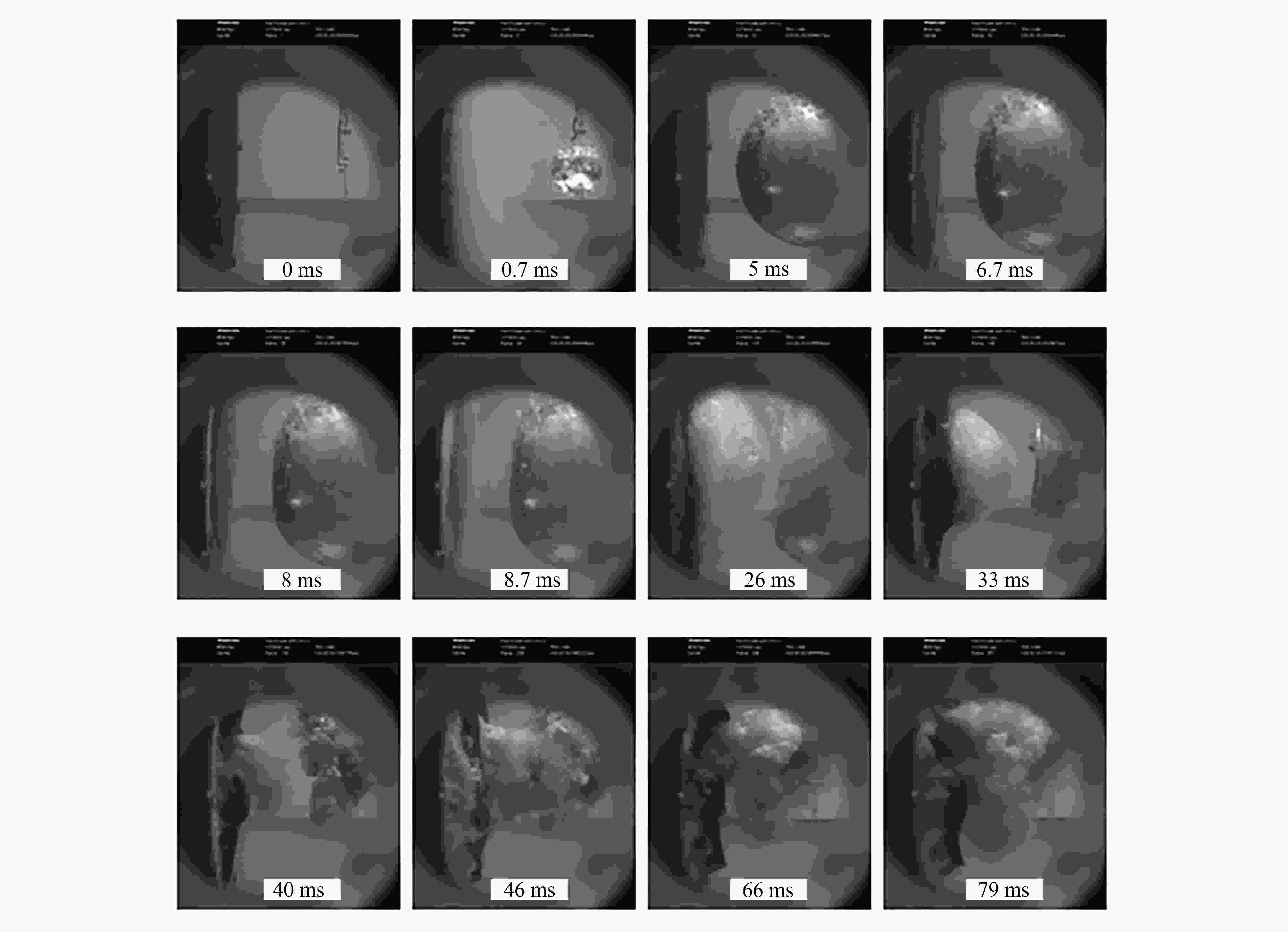

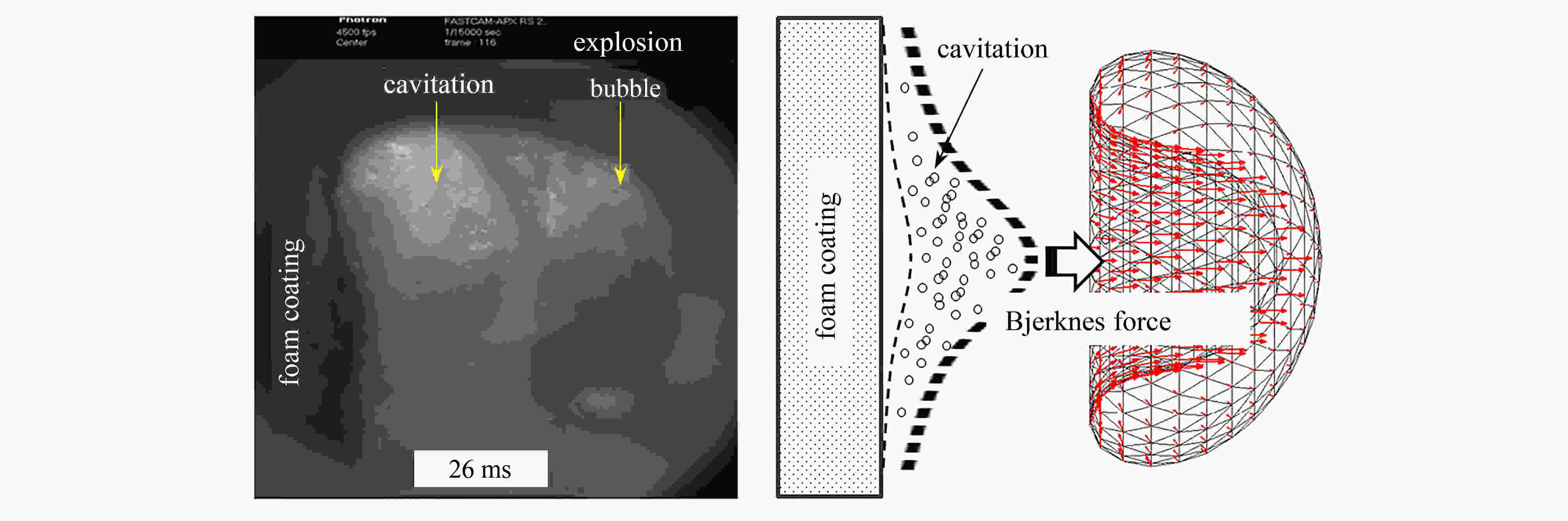

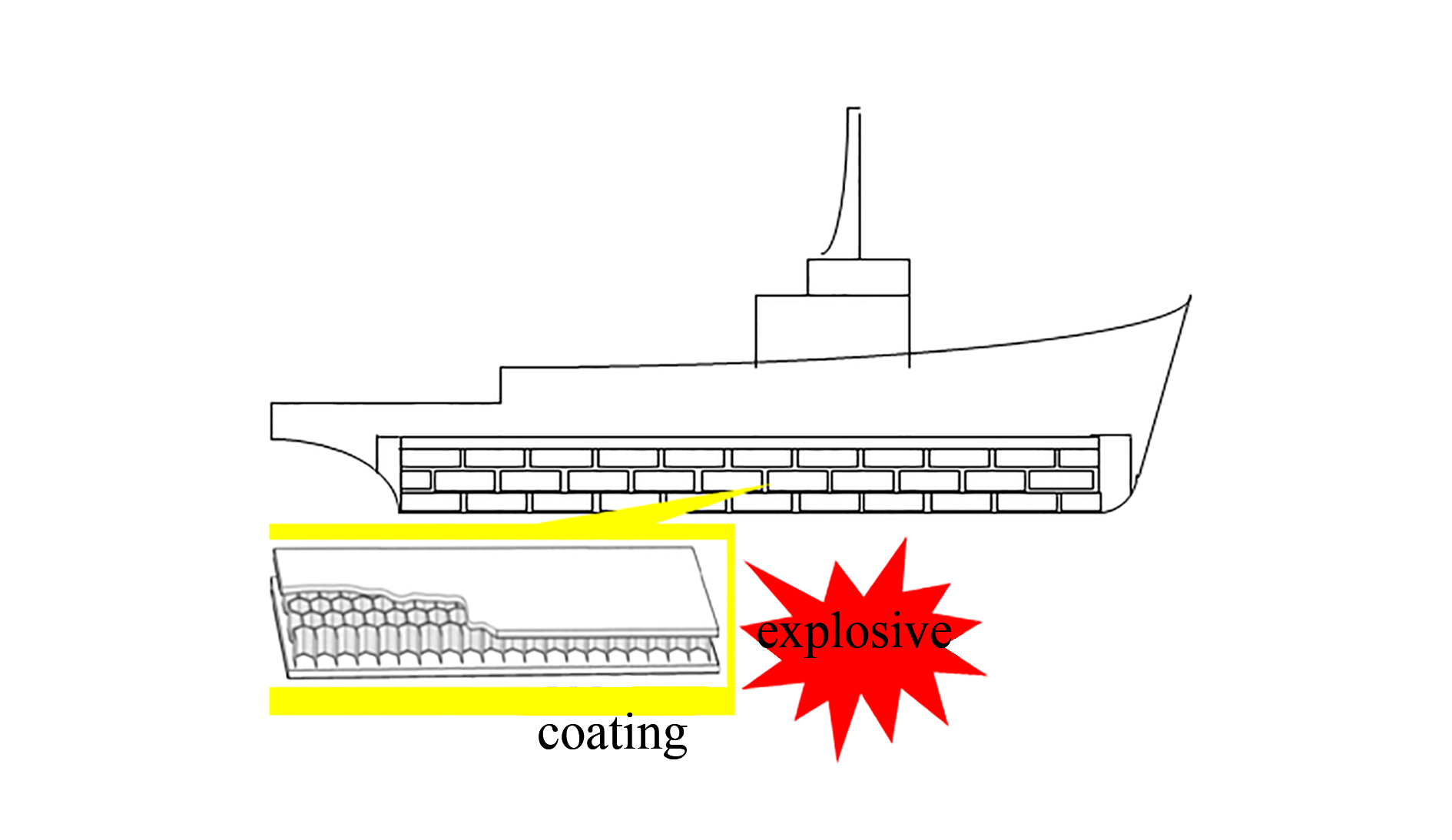

Abstract:Underwater explosion poses a serious threat to underwater structures. Flexible coatings or sandwich plates can reduce the underwater explosion impact responses of underwater structures, and make a research hotspot. Previous studies focused on the protective mechanism of the coating against shock waves, which is suitable for underwater explosion at a long distance. Besides the shock wave, the high-speed water jet towards the structure produced by explosion bubble collapse, is more deadly in the short-distance underwater explosion. In view of this situation, based on the dimensional principle, the reduced-scale similarity relationship was deduced. Through the reduced-scale-model underwater explosion test, it is found that, the cavitation micro-bubble group on the surface of the foam coating interferes with the formation process of the explosion bubble collapse high-speed water jet. The protection mechanism of the foam coating against the underwater explosion bubble collapse water jet for coated steel plates was put forward.

-

Key words:

- foam coating /

- underwater explosion /

- bubble jet /

- protective mechanism /

- reduced-scale experiment

-

表 1 水下爆炸气泡迁移相似参数

Table 1. Similar parameters of bubble migration in underwater explosion

parameter prototype geometric similarity model gravity similarity model maximum bubble radius $ {R^{\max }} $ $ \lambda _\ell {R^{\max }} $ $ \lambda _\ell {R^{\max }} $ bubble pulse period $ T $ $ {\lambda _\ell }T $ $ \lambda _l^{1/2}T $ bubble pulse peak pressure $ P_1^{\max } $ $ P_1^{\max } $ $ \lambda _l P_1^{\max } $ static pressure of bubble in water ${D + {D_0} }$ ${D + {D_0} }$ $ {\lambda _\ell }\left( {D + {D_0}} \right) $ 表 2 泡沫覆盖层模型相似参数

Table 2. Similarity parameters of the foam coating model

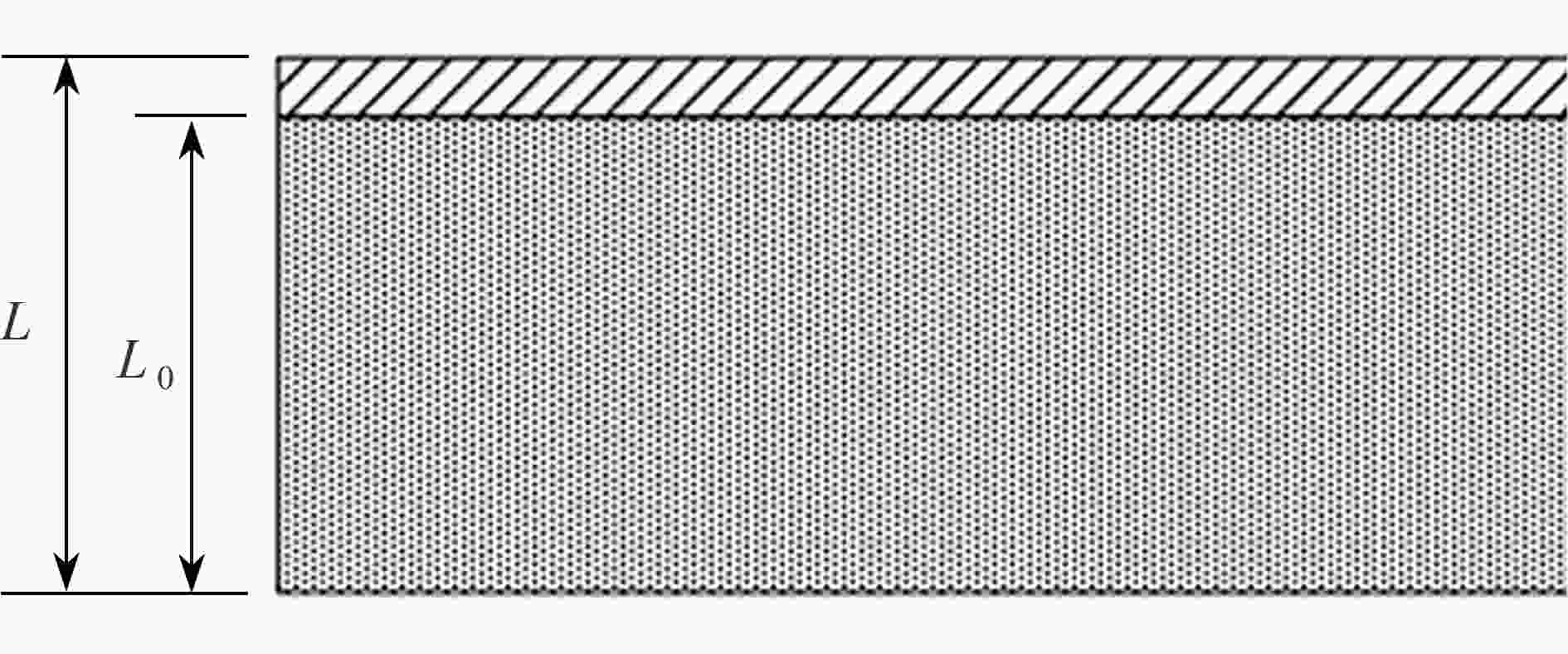

parameter prototype similarity model thickness $ h $ $\lambda_\ell h $ density $ \rho $ $\rho{ {\lambda _E}/{\lambda _l} }$ rigidity $ k $ $ {\lambda _l}{\lambda _E} $$ k $ energy absorption rate $ \dfrac{W}{{{\sigma _s}h{L^2}}} $ $ \dfrac{W}{{{\sigma _s}h{L^2}}} $ 表 3 按不同缩比相似推导原型参数

Table 3. Derivations of prototype parameters according to different scale similarities

parameter similarity model geometric similarity model gravity similarity model equivalent of detonation source 2.25 g TNT 35 kg TNT 5 kg TNT explosion source water depth H/m 1 1 25 maximum bubble radius $ {R^{\max }} $/m 0.2 5 1.8 bubble pulsation period T/ms 37 925 185 foam coating thickness h/mm 20 500 500 foam coating layer density $ \rho $/(kg/m3) 0.1 0.1 0.4 表 4 有无覆盖层圆板的射流防护参数计算表

Table 4. Calculation of jet protection parameters of circular plates with or without coating

status parameter modulus of elasticity

E/Paplate thickness

$h$/mbubble pulsation pressure

${P_{\rm{b}}}$/Pamaximum bubble radius

$ {R^{\max }} $/mblasting distance

R/mcavitation parameters

$\mu $distance parameter

$\eta $foam coated circular plate 1 × 106 0.022 3.12 × 107 0.2 0.2 0.0035 1 circular plate 2 × 1011 0.0045 3.12 × 107 0.2 0.2 144 1 -

[1] 谌勇, 华宏星, 汪玉, 等. 超弹性夹芯覆盖层的水下爆炸防护性能[J]. 爆炸与冲击, 2009, 29(4): 395-400.CHEN Yong, HUA Hongxing, WANG Yu, et al. Protective effects of hyper-elastic sandwiches coated onto metal boxes subjected to underwater explosion[J]. Explosion and Shock Waves, 2009, 29(4): 395-400. (in Chinese) [2] 姚熊亮, 于秀波, 庞福振, 等. 敷设声学覆盖层的板架结构抗冲击性能数值计算研究[J]. 工程力学, 2007, 24(11): 164-171. (YAO Xiongliang, YU Xiubo, PANG Fuzhen, et al. Numerical research on the anti-shock capability of plate-frame structure coated with acoustic covering layer[J]. Engineering Mechanics, 2007, 24(11): 164-171.(in Chinese) [3] DU Z P, WANG Y, CHEN Y, et al. A new type of rubber sandwich coated onto ship for the use of underwater explosion shock mitigating[J]. Advanced Materials Research, 2009, 79/82: 291-294. doi: 10.4028/www.scientific.net/AMR.79-82.291 [4] 张振华, 汪玉, 张立军, 等. 船体梁在水下近距爆炸作用下反直观动力行为的相似分析[J]. 应用数学和力学, 2011, 32(12): 1391-1404. (ZHANG Zhenhua, WANG Yu, ZHANG Lijun, et al. Similarity research of anomalous dynamic response of ship girder subjected to near field underwater explosion[J]. Applied Mathematics and Mechanics, 2011, 32(12): 1391-1404.(in Chinese) [5] BRETT J M, YIANNAKOPOLOUS G. A study of explosive effects in close proximity to a submerged cylinder[J]. International Journal of Impact Engineering, 2008, 35(4): 206-225. doi: 10.1016/j.ijimpeng.2007.01.007 [6] 李帅, 张阿漫, 韩蕊. 水中高压脉动气泡水射流形成机理及载荷特性研究[J]. 力学学报, 2019, 51(6): 1666-1681.LI Shuai, ZHANG Aman, HAN Rui. The mechanism of jetting behaviors of an oscilating bubble[J]. Chinese Journal of Theoretical and Applied Mechanics, 2019, 51(6): 1666-1681. (in Chinese) [7] 常青, 张敏弟, 黄国豪, 等. 不同材料边界附近气泡运动特性对比试验研究[C]//中国力学大会2019. 2019.CHANG Qing, ZHANG Mindi, HUANG Guohao, et al. Experimental study of bubble motion behavior near two different material boundarys[C]//The Chinese Congress of Theoretical and Applied Mechanics(CCTAN 2019). 2019. (in Chinese) [8] 汪斌, 张远平, 王彦平. 一种水中爆炸气泡脉动实验研究方法[J]. 高压物理学报, 2009, 23(5): 332-337. (WANG Bin, ZHANG Yuanping, WANG Yanping. An experimental method of studying underwater explosion bubble oscillation[J]. Chinese Journal of High Pressure Physics, 2009, 23(5): 332-337.(in Chinese) [9] 张效慈. 水下爆炸试验相似准则[J]. 船舶力学, 2007, 11(1): 108-118. (ZHANG Xiaoci. Similarity criteria for experiment of underwater explosion[J]. Journal of Ship Mechanics, 2007, 11(1): 108-118.(in Chinese) [10] 张效慈. 水下爆炸试验模型律的若干问题[J]. 船舶力学, 2009, 13(5): 783-787. (ZHANG Xiaoci. Some problems for model law of underwater explosion tests[J]. Journal of Ship Mechanics, 2009, 13(5): 783-787.(in Chinese) [11] BENJAMIN T B, ELLIS A T. The collapse of cavitation bubbles and the pressures thereby produced against solid boundaries[J]. Philosophical Transactions of the Royal Society of London, 1966, 260(1110): 221-240. doi: 10.1098/rsta.1966.0046 [12] BLAKE J R, GIBSON D C. Growth and collapse of a vapour cavity near a free surface[J]. Journal of Fluid Mechanics, 1981, 111: 123-140. doi: 10.1017/S0022112081002322 [13] BLAKE J R, GIBSON D C. Cavitation bubbles near boundaries[J]. Annual Review of Fluid Mechanics, 1987, 19: 99-123. doi: 10.1146/annurev.fl.19.010187.000531 [14] 张阿漫, 姚熊亮. 水深和药量的变化对水下爆炸气泡射流的影响研究[J]. 工程力学, 2008, 25(3): 222-229. (ZHANG Aman, YAO Xiongliang. The effect of charge and water depth on the underwater explosion bubble[J]. Engineering Mechanics, 2008, 25(3): 222-229.(in Chinese) [15] 张阿漫, 姚熊亮. 近自由面的多个水下爆炸气泡相互作用研究[J]. 力学学报, 2008, 40(1): 26-34. (ZHANG Aman, YAO Xiongliang. The interaction between multiple underwater explosion bubbles near free surface[J]. Chinese Journal of Theoretical and Applied Mechanics, 2008, 40(1): 26-34.(in Chinese) -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号