Surface Acoustic Wave Characterization of Equivalent Young's Moduli for Patterned Films

-

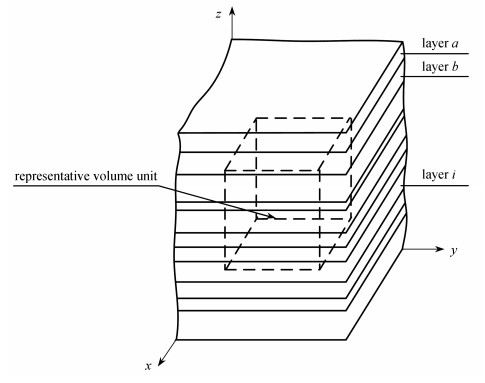

摘要: 基于分层材料等效弹性性质理论,建立了单大马士革和双大马士革结构的细观力学等效模型. 通过引入图形化结构等效弹性常数,建立了声表面波在图形化薄膜/衬底分层结构中的传播模型,利用Green函数和矩阵法计算得到了表面波理论色散曲线. 采用有限元法计算了24种不同体积比的大马士革结构数值算例,并与能量法计算结果进行了对比验证. 结果表明,厚度为300 nm的双大马士革薄膜和厚度为100 nm的单大马士革薄膜等效弹性模量平均相对误差分别为2.06%和2.27%. 验证了等效图形化结构模型的正确性以及声表面波方法表征图形化薄膜机械特性的可行性,研究结果可为开发适用于图形化薄膜、低压力的化学机械抛光工艺提供参考.Abstract: Based on the equivalent elasticity theory for layered materials, the micro-mechanics equivalent models for single and dual damascene structures were established. The equivalent elastic constant of the patterned structure was introduced, to establish the propagation model for the surface acoustic waves propagating in the layered structure of the patterned film/substrate, and the theoretical dispersion curves of the surface acoustic waves were calculated with Green's function and the matrix method. The finite element method was used to calculate 24 numerical examples of damascene structures with different volume ratios, and the results were compared with those of the strain energy method. The results show that, the average relative errors of the equivalent Young's moduli of the 300 nm-thick dual damascene film and the 100 nm-thick single damascene film are 2.06% and 2.27%, respectively. The research verifies the correctness of the equivalent patterned structure model and the feasibility of the surface acoustic wave method to characterize the mechanical properties of patterned films, and provides a reference for the development of suitable chemico-mechanical polishing technologies for patterned films under low pressure.

-

表 1 双大马士革薄膜参数(参数标记见图 3)和对应编号

Table 1. Dual damascene film parameters (see fig. 3 for parameter labels) and corresponding numbers

case No. w1/nm h1/nm w2/nm h2/nm ① homogeneous low-k material ② 50 100 50 200 ③ 50 100 60 200 ④ 50 100 90 200 ⑤ 50 100 120 200 ⑥ 50 100 150 200 ⑦ 50 100 180 200 ⑧ 50 100 210 200 ⑨ 50 100 240 200 ⑩ 50 100 270 200 ⑪ homogeneous copper material 表 2 仿真模型的波长-频率-速度值

Table 2. Wavelength-frequency-velocity values for the simulation model

wavelength λ/μm average eigenfrequency f/MHz velocity v/(m/s) 990 4.964 4 914.36 480 10.23 4 910.40 210 23.32 4 897.20 129 37.87 4 885.23 99 49.24 4 874.76 81 60.06 4 864.86 60 80.76 4 845.60 51 94.75 4 832.25 45 107.12 4 820.40 42 114.61 4 813.62 39 123.21 4 805.19 36 133.20 4 795.20 33 144.96 4 783.68 30 158.99 4 769.70 27 176.02 4 752.54 24 197.12 4 730.88 表 3 双大马士革薄膜(hf=300 nm)等效弹性模量匹配结果

Table 3. Matching results of the dual damascene structure with thickness hf=300 nm

case No. volume(Cu: low-k) SAW method strain energy method (ΔEf/Efenergy)/% Ef/GPa Efenergy/GPa ① 0∶1 (full of low-k) 9.90 10.00 1.00 ② 1∶5.0 12.87 13.23 2.72 ③ 1∶4.3 13.37 13.64 1.98 ④ 1∶2.9 14.63 15.01 2.53 ⑤ 1∶2.1 16.94 16.72 1.32 ⑥ 1∶1.6 18.74 18.96 1.16 ⑦ 1∶1.2 22.01 22.08 0.32 ⑧ 1.1∶1 26.20 26.71 1.91 ⑨ 1.4∶1 33.00 34.34 3.90 ⑩ 1.9∶1 47.74 49.39 3.34 ⑪ 1∶0 (full of Cu) 129.90 130.00 0.08 表 4 单大马士革薄膜(hf=100 nm)等效弹性模量匹配结果

Table 4. Matching results of the single damascene structure with thickness hf=100 nm

case No. volume(Cu: low-k) SAW method strain energy method (ΔEf/Efenergy)/% Ef/GPa Efenergy/GPa ① 1∶9 11.78 12.06 2.32 ② 1∶7 12.07 12.48 3.29 ③ 1∶5 12.87 13.23 2.72 ④ 1∶4 13.56 13.83 1.95 ⑤ 1∶3 14.73 14.79 0.41 ⑥ 1∶2 16.76 16.59 1.02 ⑦ 1∶1 21.79 21.58 0.97 ⑧ 2∶1 30.52 30.27 0.83 ⑨ 3∶1 37.24 37.68 1.17 ⑩ 4∶1 42.87 44.02 2.61 ⑪ 5∶1 47.32 49.42 4.25 ⑫ 7∶1 56.28 58.69 4.11 ⑬ 9∶1 63.50 66.06 3.88 -

[1] EDELSTEIN D, HEIDENREICH J, GOLDBLATT R, et al. Full copper wiring in a sub-0.25 μm CMOS ULSI technology[C]//1997 International Electron Devices Meeting (IEDM). Washington DC, USA, 1997: 773-776. [2] 王阳元, 康晋锋. 超深亚微米集成电路中的互连问题: 低k介质与Cu的互连集成技术[J]. 半导体学报, 2002, 23(11): 1121-1134. https://www.cnki.com.cn/Article/CJFDTOTAL-BDTX200211000.htmWANG Yangyuan, KANG Jinfeng. Development of ULSI interconnect integration technology: copper interconnect with low-k dielectrics[J]. Chinese Journal of Semiconductors, 2002, 23(11): 1121-1134. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BDTX200211000.htm [3] HUANG K Y, CHI H Y, KAO P K, et al. Atmospheric pressure plasma jet assisted synthesis of zeolite-based low-k thin films[J]. ACS Applied Materials & Interfaces, 2018, 10(1): 900-908. [4] LI G L, ZHENG G, DING Z J, et al. High-performance ultra-low-k fluorine-doped nanoporous organosilica films for inter-layer dielectric[J]. Journal of Materials Science, 2019, 54(3): 2379-2391. doi: 10.1007/s10853-018-3013-x [5] GHIDELLI M, SEBASTIANI M, COLLET C, et al. Determination of the elastic moduli and residual stresses of freestanding Au-TiW bilayer thin films by nanoindentation[J]. Materials & Design, 2016, 106: 436-445. doi: 10.3969/j.issn.1007-9629.2016.03.004 [6] HUMOOD M, ASIF A, GUIN T, et al. Nanoindentation and nanoscratch of sub-micron polymer nanocomposite films on compliant substrate[J]. Thin Solid Films, 2021, 736: 138905. doi: 10.1016/j.tsf.2021.138905 [7] JAVED H, MERLE B, PREISS E, et al. Mechanical characterization of metallic thin films by bulge and scratch testing[J]. Surface and Coatings Technology, 2016, 289: 69-74. doi: 10.1016/j.surfcoat.2016.01.051 [8] ZIZKA J, KING S, EVERY A, et al. Acoustic phonons and mechanical properties of ultra-thin porous low-k films: a surface Brillouin scattering study[J]. Journal of Electronic Materials, 2018, 47(7): 3942-3950. doi: 10.1007/s11664-018-6276-8 [9] OVCHINNIKOV I S, VISHNEVSKIY A S, SEREGIN D S, et al. Evaluation of mechanical properties of porous OSG films by PFQNM AFM and benchmarking with traditional instrumentation[J]. Langmuir, 2020, 36(32): 9377-9387. doi: 10.1021/acs.langmuir.0c01054 [10] KOPYCINSKA-MVLLER M, CLAUSNER A, YEAP K B, et al. Mechanical characterization of porous nano-thin films by use of atomic force acoustic microscopy[J]. Ultramicroscopy, 2016, 162: 82-90. doi: 10.1016/j.ultramic.2015.12.001 [11] SCHNEIDER D, SCHULTRICH B, SCHEIBE H J, et al. A laser-acoustic method for testing and classifying hard surface layers[J]. Thin Solid Films, 1998, 332(1/2): 157-163. [12] HERNANDEZ-VALLE F, DUTTON B, EDWARDS R S. Laser ultrasonic characterisation of branched surface-breaking defects[J]. NDT & E International, 2014, 68: 113-119. [13] LIU Z, LIN B, LIANG X, et al. Inversion of surface damage and residual stress in ground silicon wafers by laser surface acoustic wave technology[J]. Ultrasonics, 2021, 113: 106367. doi: 10.1016/j.ultras.2021.106367 [14] FALL D, COMPOINT F, DUQUENNOY M, et al. Surface acoustic wave characterization of optical sol-gel thin layers[J]. Ultrasonics, 2016, 68: 102-107. doi: 10.1016/j.ultras.2016.02.006 [15] ALVES C F A, MARQUES L, CALDERON V S, et al. An experimental and theoretical study on the crystal structure and elastic properties of Ta1-xOx coatings[J]. Surface and Coatings Technology, 2019, 364: 289-297. doi: 10.1016/j.surfcoat.2019.02.054 [16] NAKAMURA N, YOKOMURA R, TAKEUCHI N, et al. Elastic stiffness of metallic multilayers studied by picosecond ultrasonics: improved interpretation of interface elasticity[J]. Japanese Journal of Applied Physics, 2019, 58(7): 075504. doi: 10.7567/1347-4065/ab242b [17] 古普塔S, 维施瓦卡尔玛S K, 玛里D K, 等. 密度和刚度线性变化对非均匀地壳层中扭转表面波传播的影响[J]. 应用数学和力学, 2012, 33(10): 1156-1169. doi: 10.3879/j.issn.1000-0887.2012.10.002GUPTA S, VISHWAKARMA S K, MAJHI D K, et al. Influence of linearly varying density and rigidity on torsional surface waves in an inhomogeneous crustal layer[J]. Applied Mathematics and Mechanics, 2012, 33(10): 1156-1169. (in Chinese) doi: 10.3879/j.issn.1000-0887.2012.10.002 [18] 库玛R, 库玛R, 黄锋. 各向同性弹性半空间与带孔隙横观各向同性热弹性材料界面上波的传播[J]. 应用数学和力学, 2010, 31(9): 1101-1117. doi: 10.3879/j.issn.1000-0887.2010.09.010KUMAR R, KUMAR R, HUANG Feng. Propagation of wave at the boundary surface of transversely isotropic thermoelastic material with voids and isotropic elastic half-space[J]. Applied Mathematics and Mechanics, 2010, 31(9): 1101-1117. (in Chinese) doi: 10.3879/j.issn.1000-0887.2010.09.010 [19] LI C, GUAN G, WANG R, et al. Mechanical characterization of skin using surface acoustic waves[M]//Imaging in Dermatology. New York: Academic Press, 2016: 327-340. [20] ZHANG X, ZHOU B, OSBORN T, et al. Lung ultrasound surface wave elastography for assessing interstitial lung disease[J]. IEEE Transactions on Biomedical Engineering, 2019, 66(5): 1346-1352. doi: 10.1109/TBME.2018.2872907 [21] 崔春丽, 徐耀玲. 预测纳米纤维复合材料有效弹性性能的界面模型和界面相模型[J]. 应用数学和力学, 2022, 43(8): 877-887. doi: 10.21656/1000-0887.420231CUI Chunli, XU Yaoling. The interface model and the interphase model for predicting the effective elastic properties of nano-fiber composites[J]. Applied Mathematics and Mechanics, 2022, 43(8): 877-887. (in Chinese) doi: 10.21656/1000-0887.420231 [22] 陈海玉, 徐福卫. 细观等效理论预测再生混凝土宏观力学参数[J]. 应用数学和力学, 2022, 43(7): 772-782. doi: 10.21656/1000-0887.420079CHEN Haiyu, XU Fuwei. Prediction of the macroscopic mechanics properties of recycled aggregate concrete based on the mesoscopic equivalence theory[J]. Applied Mathematics and Mechanics, 2022, 43(7): 772-782. (in Chinese) doi: 10.21656/1000-0887.420079 [23] 李新平, 代翼飞, 郭运华, 等. 地下洞室锚固结构的力学特性与锚固机理研究[J]. 金属矿山, 2009(9): 19-23. doi: 10.3321/j.issn:1001-1250.2009.09.003LI Xinping, DAI Yifei, GUO Yunhua, et al. Study on the mechanical properties and anchoring mechanism in anchored structure of underground cavity[J]. Metal Mine, 2009(9): 19-23. (in Chinese) doi: 10.3321/j.issn:1001-1250.2009.09.003 [24] LO M K, DAZZI A, MARCOTT C A, et al. Nanoscale chemical-mechanical characterization of nanoelectronic low-k dielectric/Cu interconnects[J]. ECS Journal of Solid State Science and Technology, 2015, 5(4): P3018-P3024. [25] TEWARY V K. Green's-function method for modeling surface acoustic wave dispersion in anisotropic material systems and determination of material parameters[J]. Wave Motion, 2004, 40(4): 399-412. doi: 10.1016/j.wavemoti.2004.02.007 [26] XIAO X, SHAN X M, TAO Y, et al. Finite element model of surface acoustic wave method for mechanical characterization of patterned thin films of the ultra-large scaled integrated interconnect[J]. Journal of Nanoscience and Nanotechnology, 2013, 13(2): 1602-1606. doi: 10.1166/jnn.2013.6092 [27] 张小明, 高安儒, 王现辉, 等. 基于有限元特征频率法的功能梯度矩形截面杆导波频散特性研究[J]. 应用力学学报, 2021, 38(5): 2162-2167. doi: 10.11776/cjam.38.05.C101ZHANG Xiaoming, GAO Anru, WANG Xianhui, et al. Dispersion characteristics of guided waves in functionally graded rectangular bars based on a finite element characteristic frequency method[J]. Chinese Journal of Applied Mechanics, 2021, 38(5): 2162-2167. (in Chinese) doi: 10.11776/cjam.38.05.C101 [28] ZHANG W, DAI G, WANG F, et al. Using strain energy-based prediction of effective elastic properties in topology optimization of material microstructures[J]. Acta Mechanica Sinica, 2007, 23(1): 77-89. doi: 10.1007/s10409-006-0045-2 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号