Enhancement Strategies for Mechanical Robustness of Carbon Aerogels and Their Applications

-

摘要:

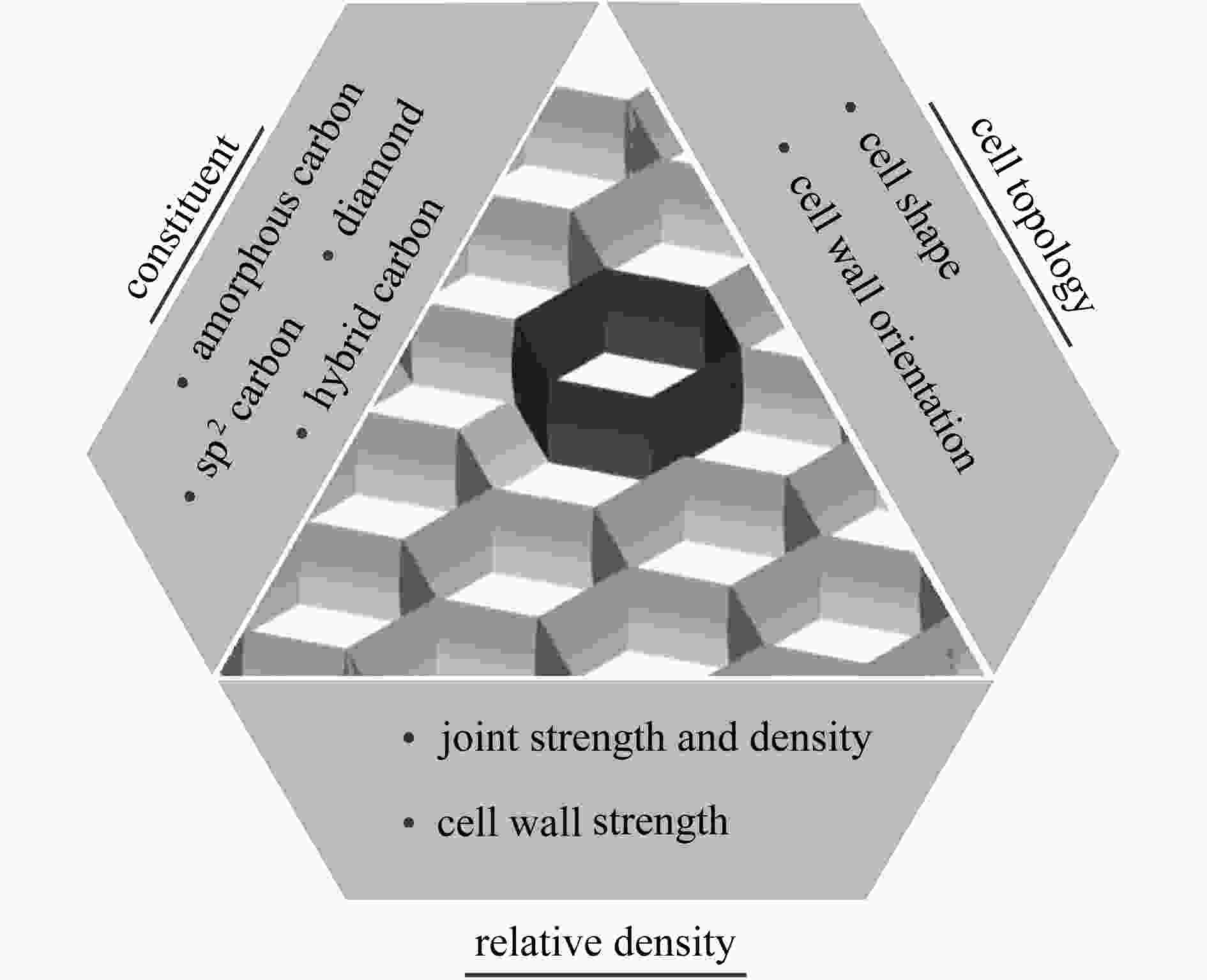

作为一种轻质多孔材料,碳气凝胶是一类具有高孔隙率、低密度和优异环境稳定性的碳质多功能固体材料,这些独特性能的结合使得它们在柔性传感器、能源设备、声学设备和环境保护等领域得到广泛应用。然而,在现有多孔材料中普遍存在着机械鲁棒性和稀疏三维网络结构间的矛盾。良好的鲁棒性可以确保气凝胶在应用过程中的结构完整性和性能稳定性,而稀疏三维网络结构则是确保气凝胶材料轻质多孔的结构前提,这一矛盾是材料科学、固体力学和设计应用等诸多领域研究者面临的共同挑战。该文综述了常见的国内外超轻碳气凝胶的鲁棒性增强策略,包括细胞壁(cell wall)增强、细胞壁取向调控、细胞壁拓扑结构设计和结点强化(joint reinforcement)。此外,该文总结了在不引入高分子弹性体的情况下实现超轻全碳气凝胶的拉伸弹性的设计原则,简要概述了高鲁棒性碳气凝胶的新应用,并对该领域尚待解决的问题提出了展望。

Abstract:As a newly emerging light porous material, carbon aerogels are a class of carbonaceous solid materials with high porosity, low density and excellent environmental stability. With the combination of high elasticity, high energy absorption, as well as special properties such as shock absorption, sound absorption and electromagnetic shielding, carbon aerogels are both functional and structural, and widely applied in the fields of flexible sensors, energy equipment, acoustic equipment and environmental protection. However, the existing general conflicts between the mechanical robustness and the intrinsic sparse network in porous aerogel materials have been a common challenge faced by researchers in fields of material science, solid mechanics, design, application and so on. Good robustness could ensure the structural integrity and performance stability of aerogels in the application process, while the sparse network is the prerequisite to ensure the lightweight and porous structure of aerogels. Here, the recent enhancement strategies for the mechanical robustness, including cell-wall strengthening, cell-wall orientation, pore topology controlling and joint reinforcement, were discussed. Specially, the advanced design principles to realize the tensile elasticity in ultra-light all-carbon aerogels without intrinsic stretchable elastomers, were summarized. In addition, the recent applications of robust carbon aerogels were reviewed and the problems to be solved in this field were listed.

-

Key words:

- carbon aerogel /

- mechanical robustness /

- micro-structure control /

- stretchability

-

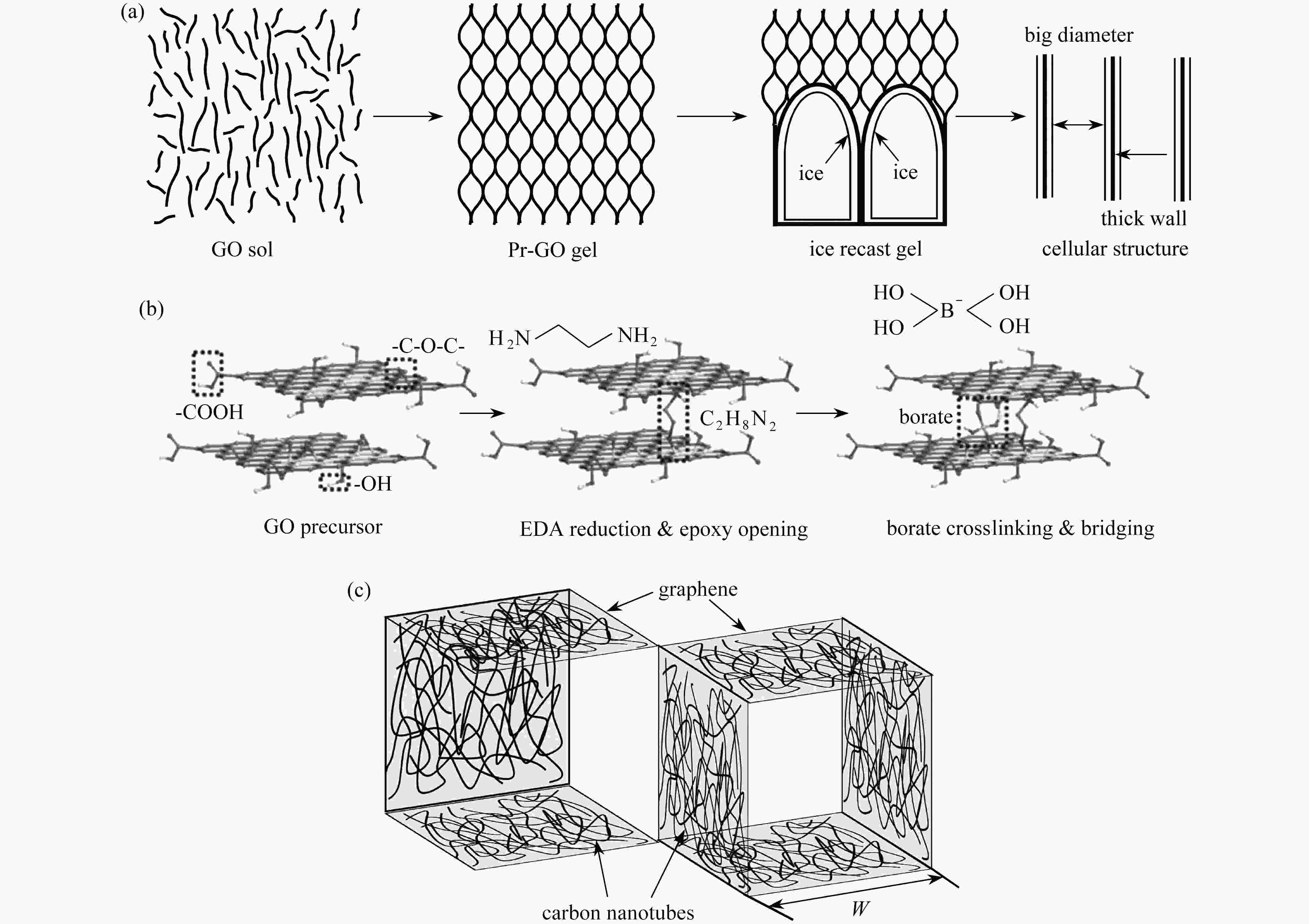

图 2 细胞壁增强:(a)厚石墨烯细胞壁形成机理示意图;(b)硼酸盐交联对石墨烯自组装影响示意图;(c)石墨烯和碳纳米管协同组装结构单元示意图

Figure 2. Cell wall strengthening: (a) schematics of the formation mechanism of the thick graphene cellular walls; (b) schematics of the borate crosslinking and bridging effects on graphene self-assembly; (c) schematics of idealized building cells made by synergistic assembly of graphene and carbonnanotubes

图 3 细胞壁取向:(a)碳气凝胶中的软木结构; (b)海棠茎的多尺度结构; (c)长程层状多拱微结构; (d)径向中心对称结构与螺旋结构

Figure 3. Cell wall orientations: (a) the top view and the side view of cork-like structures in the CA monolith; (b) the multiscale architecture of the Thalia dealbata stem; (c) the lamellar multi-arch microstructure with long-range alignment; (d) the radial and centrosymmetric structure and the spiral structure

图 4 调节孔隙网络拓扑结构的表面活性剂发泡方法:(a) 表面活性剂-发泡法从乳化、单向冷冻到冷冻干燥的结构演变; (b) 微流体过程产生的微型球形实心壳气泡及其三维组装示意图

Figure 4. A surfactant foaming method to regulate the pore network topology: (a) structural evolution of the surfactant foaming method from emulsification, unidirectional freezing to freeze drying; (b) the diagram of micro spherical solid shell bubbles produced via the microfluidic process and its 3D assembly

9 高鲁棒性碳气凝胶的应用:(a) 应变传感器响应图;(b) 压力传感器响应图;(c) 磁传感器响应图;(d) 磁驱动示意图;(e) 场致应变随磁场强度变化图;(f) 电激活压缩和恢复的形状记忆行为;(g) 碳气凝胶电极的驱动机制示意图;(h) 四驱动臂抓斗机器人工作示意图;(i) 电阻随拉伸应变变化图;(j) 电阻与曲率半径关系图;(k) 导体在拉伸、扭曲、弯曲和挤压过程中的电阻变化

9. Applications of robust carbon aerogels: (a) the strain sensor response; (b) the pressure sensor response; (c) the magnetism sensor response; (d) the diagram of the magnetic actuation; (e) field-induced strains as a function of the magnetic field intensity; (f) electrically activated shape-memory behaviors of compression and recovery; (g) the schematic diagram of actuation mechanism of the carbon aerogel electrode; (h) operations of a grapple robot consisting of 4 actuator arms; (i) the resistance vs. the tensile strain; (j) the resistance vs. the radius of curvature; (k) the conductor resistance changes during stretching, twisting, bending and pressing

-

[1] PEKALA R W, MAYER S T, KASCHMITTER J L, et al. Carbon Aerogels: an Update on Structure, Properties, and Applications[M]//Sol-Gel Processing and Applications. Boston, MA: Springer, 1994: 369-377. [2] PEKALA R W, ALVISO C T. Carbon aerogels and xerogels[C]//Materials Research Society Symposia Proceedings. 1999, 270. DOI: 10.1557/PROC-270-3. [3] PEKALA R W, ALVISO C T, KONG F M, et al. Aerogels derived from multifunctional organic monomers[J]. Journal of Non-Crystalline Solids, 1992, 145: 90-98. doi: 10.1016/S0022-3093(05)80436-3 [4] FUNG A W P, WANG Z H, LU K, et al. Characterization of carbon aerogels by transport measurements[J]. Journal of Materials Research, 1993, 8: 1875. doi: 10.1557/JMR.1993.1875 [5] HANZAWA Y, KANEKO K, PEKALA R W, et al. Activated carbon aerogels[J]. Langmuir, 1996, 12(26): 61-67. [6] IIJIMA S, ICHIHASHI T. Single-shell carbon nanotubes of 1-nm diameter[J]. Nature, 1993, 363: 603-605. doi: 10.1038/363603a0 [7] KROTO H W, HEATH J R, OBRIEN S C, et al. C60: buckminsterfullerene[J]. Nature, 1985, 318: 162-163. doi: 10.1038/318162a0 [8] NOVOSELOV K S, GEIM A K, MOROZOV S V, et al. Electric field effect in atomically thin carbon films[J]. Science, 2004, 306: 666-669. doi: 10.1126/science.1102896 [9] ZHAO J H, WEI N, FAN Z Z, et al. The mechanical properties of three types of carbon allotropes[J]. Nanotechnology, 2013, 24(9): 095702. doi: 10.1088/0957-4484/24/9/095702 [10] EVEN W R, CROCKER R W, HUNTER M C, et al. Surface and near-surface structure in carbon microcellular materials produced from organic aerogels and xerogels[J]. Journal of Non-Crystalline Solids, 1995, 186: 191-199. doi: 10.1016/0022-3093(95)00061-5 [11] SCHWERTFEGER F, SCHUBERT U. Generation of carbonaceous structures in silica aerogel[J]. Chemistry of Materials, 1995, 7(10): 1909-1914. doi: 10.1021/cm00058a023 [12] WANG J, ELLSWORTH M. Graphene aerogels[J]. ECS Transactions, 2009, 19(5): 241. doi: 10.1149/1.3119548 [13] WORSLEY M A, PAUZAUSKIE P J, OLSON T Y, et al. Synthesis of graphene aerogel with high electrical conductivity[J]. Journal of the American Chemical Society, 2010, 132(40): 14067-14069. doi: 10.1021/ja1072299 [14] ZOU J H, LIU J H, KARAKOTI A S, et al. Ultralight multiwalled carbon nanotube aerogel[J]. ACS Nano, 2010, 4(12): 7293-7302. doi: 10.1021/nn102246a [15] BRYNING M B, MILKIE D E, ISLAM M F, et al. Carbon nanotube aerogels[J]. Advanced Materials, 2007, 19(5): 661-664. doi: 10.1002/adma.200601748 [16] PAUZAUSKIE P J, CROWHURST J C, WORSLEY M A, et al. Synthesis and characterization of a nanocrystalline diamond aerogel[J]. Physical and Life Sciences Directorate, 2011, 108(21): 8550-8553. [17] KHARISOVA O V, IBARRA TORRES C E, GONZÁLEZ L T, et al. All-carbon hybrid aerogels: synthesis, properties, and applications[J]. Industrial & Engineering Chemistry Research, 2019, 58(36): 16258-16286. [18] RITCHIE R O. The conflicts between strength and toughness[J]. Nature Materials, 2011, 10(11): 817-822. doi: 10.1038/nmat3115 [19] WIENER M, REICHENAUER G, BRAXMEIER S, et al. Carbon aerogel-based high-temperature thermal insulation[J]. International Journal of Thermophysics, 2009, 30(4): 1372-1385. doi: 10.1007/s10765-009-0595-1 [20] ZHONG J, MENG J, GUI X C, et al. Nanocarbon aerogel complexes inspired by the leaf structure[J]. Carbon, 2014, 77: 637-644. doi: 10.1016/j.carbon.2014.05.068 [21] HU E, SHANG S, TAO X M, et al, Regeneration and reuse of highly polluting textile dyeing effluents through catalytic ozonation with carbon aerogel catalysts[J]. Journal of Cleaner Production, 2016, 137: 1055-1065. [22] PORADA S, ZHAO R, VAN DER WAL A, et al. Review on the science and technology of water desalination by capacitive deionization[J]. Progress in Materials Science, 2013, 58(8): 1388-1442. doi: 10.1016/j.pmatsci.2013.03.005 [23] FRACKOWIAK E, BEGUIN F. Carbon materials for the electrochemical storage of energy in capacitors[J]. Carbon, 2001, 39(6): 937-950. doi: 10.1016/S0008-6223(00)00183-4 [24] ZHANG L L, ZHAO X S. Carbon-based materials as supercapacitor electrodes[J]. Chemical Society Reviews, 2009, 38(9): 2520-2531. doi: 10.1039/b813846j [25] SALIMIAN S, ZADHOUSH A, NAEIMIRAD M, et al. A review on aerogel: 3D nanoporous structured fillers in polymer-based nanocomposites[J]. Polymer Composites, 2018, 39(10): 3383-3408. doi: 10.1002/pc.24412 [26] ASHBY M F, EVANS T, FLECK N A, et al. Metal Foams: a Design Guide[M]. Elsevier, 2000. [27] GEIM A K. Graphene: status and prospects[J]. Science, 2009, 324(5934): 1530-1534. doi: 10.1126/science.1158877 [28] YANG H S, ZHANG T P, JIANG M, et al. Ambient pressure dried graphene aerogels with superelasticity and multifunctionality[J]. Journal of Materials Chemistry A, 2015, 3(38): 19268-19272. doi: 10.1039/C5TA06452J [29] WAN S J, CHEN Y, FANG S L, et al. High-strength scalable graphene sheets by freezing stretch-induced alignment[J]. Nature Materials, 2021, 20(5): 624-631. doi: 10.1038/s41563-020-00892-2 [30] ZHOU T Z, CHENG Q F. Chemical strategies for making strong graphene materials[J]. Angewandte Chemie International Edition, 2021, 60(34): 18397-18410. doi: 10.1002/anie.202102761 [31] XU X, ZHANG Q Q, YU Y K, et al. Naturally dried graphene aerogels with superelasticity and tunable Poisson’s ratio[J]. Advanced Materials, 2016, 28(41): 9223-9230. doi: 10.1002/adma.201603079 [32] SUN H Y, XU Z, GAO C. Multifunctional, ultra-flyweight, synergistically assembled carbon aerogels[J]. Advanced Materials, 2013, 25(18): 2554-2560. doi: 10.1002/adma.201204576 [33] WU D C, CHEN X, LU S H, et al. Study on synergistic effect of ordered mesoporous carbon and carbon aerogel during electrochemical charge-discharge process[J]. Microporous and Mesoporous Materials, 2010, 131(1/3): 261-264. [34] SUN W, GAO G H, DU Y C, et al. A facile strategy for fabricating hierarchical nanocomposites of V2O5 nanowire arrays on a three-dimensional N-doped graphene aerogel with a synergistic effect for supercapacitors[J]. Journal of Materials Chemistry A, 2018, 6(21): 9938-9947. doi: 10.1039/C8TA01448E [35] YAO X, GUO G L, ZHAO Y, et al. Synergistic effect of mesoporous Co3O4 nanowires confined by N-doped graphene aerogel for enhanced lithium storage[J]. Small, 2016, 12(28): 3849-3860. doi: 10.1002/smll.201600632 [36] QIU L, LIU J Z, CHANG S L Y, et al. Biomimetic superelastic graphene-based cellular monoliths[J]. Nature Communications, 2012, 3(1): 1241. [37] HU H, ZHAO Z B, WAN W B, et al. Ultralight and highly compressible graphene aerogels[J]. Advanced Materials, 2013, 25: 2219. doi: 10.1002/adma.201204530 [38] DEVILLE S. Freeze-casting of porous ceramics: a review of current achievements and issues[J]. Advanced Engineering Materials, 2008, 10(3): 155-169. doi: 10.1002/adem.200700270 [39] RICE R W. Porosity of Ceramics: Properties and Applications[M]. New York: CRC Press, 1998. [40] OHJI T, FUKUSHIMA M. Macro-porous ceramics: processing and properties[J]. International Materials Reviews, 2012, 57(2): 115-131. doi: 10.1179/1743280411Y.0000000006 [41] BAI H, CHEN Y, DELATTRE B, et al. Bioinspired large-scale aligned porous materials assembled with dual temperature gradients[J]. Science Advances, 2015, 1(11): e1500849. doi: 10.1126/sciadv.1500849 [42] GAO H L, ZHU Y B, MAO L B, et al. Super-elastic and fatigue resistant carbon material with lamellar multi-arch microstructure[J]. Nature Communications, 2016, 7(1): 12920. [43] WANG C, CHEN X, WANG B, et al. Freeze-casting produces a graphene oxide aerogel with a radial and centrosymmetric structure[J]. ACS Nano, 2018, 12(6): 5816-5825. doi: 10.1021/acsnano.8b01747 [44] ASHBY M F. The properties of foams and lattices[J]. Philosophical Transactions of the Royal Society A, 2006, 364(1838): 15-30. doi: 10.1098/rsta.2005.1678 [45] GIBSON L J. Mechanical behavior of metallic foams[J]. Annual Reviews of Materials Science, 2000, 30(1): 191-227. doi: 10.1146/annurev.matsci.30.1.191 [46] OH M J, LEE J H, YOO P J. Graphene-based ultralight compartmentalized isotropic foams with an extremely low thermal conductivity of 5.75 mW·m–1·K–1[J]. Advanced Functional Materials, 2021, 31(5): 2007392. doi: 10.1002/adfm.202007392 [47] BARG S, PEREZ F M, NI N, et al. Mesoscale assembly of chemically modified graphene into complex cellular networks[J]. Nature Communications, 2014, 5(1): 4328. [48] YANG H S, LI Z L, LU B, et al. Reconstruction of inherent graphene oxide liquid crystals for large-scale fabrication of structure-intact graphene aerogel bulk toward practical applications[J]. ACS Nano, 2018, 12(11): 11407-11416. doi: 10.1021/acsnano.8b06380 [49] YANG H S, LI Z L, SUN G Q, et al. Superplastic air-dryable graphene hydrogels for wet-press assembly of ultrastrong superelastic aerogels with infinite macroscale[J]. Advanced Functional Materials, 2019, 29(26): 1901917. doi: 10.1002/adfm.201901917 [50] YEO S J, OH M J, JUN H M, et al. A plesiohedral cellular network of graphene bubbles for ultralight, strong, and superelastic materials[J]. Advanced Materials, 2018, 30(45): 1802997. doi: 10.1002/adma.201802997 [51] LEE J H, OH M J, YOO P J. Broad tunability in mechanical properties of closed cellular foams using micro-bubble assembly of graphene/silica nanocomposites[J]. Materials & Design, 2021, 202: 109558. [52] CHHOWALLA M, JARIWALA D. Hyperbolic 3D architectures with 2D ceramics[J]. Science, 2019, 363(6428): 694-695. doi: 10.1126/science.aaw5670 [53] XU X, ZHANG Q, HAO M, et al. Double-negative-index ceramic aerogels for thermal superinsulation[J]. Science, 2019, 363(6428): 723-727. doi: 10.1126/science.aav7304 [54] JIANG Y Q, XU Z, HUANG T Q, et al. Direct 3D printing of ultralight graphene oxide aerogel microlattices[J]. Advanced Functional Materials, 2018, 28(16): 1707024. doi: 10.1002/adfm.201707024 [55] ZHANG Y Y, ZHU G M, DONG B Q, et al. Interfacial jamming reinforced Pickering emulgel for arbitrary architected nanocomposite with connected nanomaterial matrix[J] Nature Communications, 2021, 12(1): 111. [56] ZHU C, HAN T Y J, DUOSS E B, et al. Highly compressible 3D periodic graphene aerogel microlattices[J]. Nature Communications, 2015, 6(1): 6962. [57] XU M, FUTABA D N, YAMADA T, et al. Carbon nanotubes with temperature-invariant viscoelasticity from –196 to 1 000 ℃[J]. Science, 2010, 330(6009): 1364-1368. [58] KIM K H, OH Y, ISLAM M F. Graphene coating makes carbon nanotube aerogels superelastic and resistant to fatigue[J]. Nature Nanotechnology, 2012, 7(9): 562-566. doi: 10.1038/nnano.2012.118 [59] ZHANG F, REN D H, HUANG L Q, et al. 3D Interconnected conductive graphite nanoplatelet welded carbon nanotube networks for stretchable conductors[J]. Advanced Functional Materials, 2021, 31(49): 2107082. doi: 10.1002/adfm.202107082 [60] GUO F, JIANG Y Q, XU Z, et al. Highly stretchable carbon aerogels[J]. Nature Communications, 2018, 9(1): 881. doi: 10.1038/s41467-017-02088-w [61] GAO H L, WANG Z Y, CUI C, et al. A highly compressible and stretchable carbon spring for smart vibration and magnetism sensors[J]. Advanced Materials, 2021, 33(39): 2170308. doi: 10.1002/adma.202170308 [62] LIANG Y R, LIANG X L, ZHANG Z Y, et al. High mobility flexible graphene field-effect transistors and ambipolar radio-frequency circuits[J]. Nanoscale, 2015, 7(25): 10954-10962. doi: 10.1039/C5NR02292D [63] BOLLELLA P, FUSCO G, TORTOLINI C, et al. Beyond graphene: electrochemical sensors and biosensors for biomarkers detection[J]. Biosensors and Bioelectronics, 2017, 89(1): 152-166. [64] ZHUO H, HU Y J, TONG X, et al. A supercompressible, elastic, and bendable carbon aerogel with ultrasensitive detection limits for compression strain, pressure, and bending angle[J]. Advanced Materials, 2018, 30(18): 1706705. doi: 10.1002/adma.201706705 [65] TIAN Y, HAN J K, YANG J K, et al. A highly sensitive graphene aerogel pressure sensor inspired by fluffy spider leg[J]. Advanced Materials Interfaces, 2021, 8(15): 2100511. doi: 10.1002/admi.202100511 [66] PANG K, SONG X, XU Z, et al. Hydroplastic foaming of graphene aerogels and artificially intelligent tactile sensors[J]. Science Advances, 2020, 6(46): eabd4045. doi: 10.1126/sciadv.abd4045 [67] CAO X Y, ZHANG J, CHEN S W, et al. 1D/2D nanomaterials synergistic, compressible, and response rapidly 3D graphene aerogel for piezoresistive sensor[J]. Advanced Functional Materials, 2020, 30(35): 2003618. doi: 10.1002/adfm.202003618 [68] SAMAD Y A, LI Y Q, ALHASSAN S M, et al. Novel graphene foam composite with adjustable sensitivity for sensor applications[J]. ACS Applied Materials & Interfaces, 2015, 7(17): 9195-9202. [69] LI C W, JIANG D G, LIANG H, et al. Superelastic and arbitrary-shaped graphene aerogels with sacrificial skeleton of melamine foam for varied applications[J]. Advanced Functional Materials, 2018, 28(8): 1704674. doi: 10.1002/adfm.201704674 [70] LIANG J J, ZHAO Z B, TANG Y C, et al. Covalent bonds-integrated graphene foam with superb electromechanical properties as elastic conductor and compressive sensor[J]. Carbon, 2019, 147: 206-213. doi: 10.1016/j.carbon.2019.02.087 [71] QIN Y Y, PENG Q Y, DING Y J, et al. Lightweight, superelastic, and mechanically flexible graphene/polyimide nanocomposite foam for strain sensor application[J]. ACS Nano, 2015, 9(9): 8933-8941. doi: 10.1021/acsnano.5b02781 [72] HUANG J K, ZENG J B, LIANG B Q, et al. Multi-arch-structured all-carbon aerogels with superelasticity and high fatigue resistance as wearable sensors[J]. ACS Applied Materials & Interfaces, 2020, 12(14): 16822-16830. [73] MA Y X, YU M, LIU J H, et al. Ultralight interconnected graphene-amorphous carbon hierarchical foam with mechanical resiliency for high sensitivity and durable strain sensors[J]. ACS Applied Materials & Interfaces, 2017, 9(32): 27127-27134. [74] MA W J, JIANG Z C, LU T, et al. Lightweight, elastic and superhydrophobic multifunctional nanofibrous aerogel for self-cleaning, oil/water separation and pressure sensing[J]. Chemical Engineering Journal, 2021, 430: 132989. [75] WANG Z Y, GAO W L, ZHANG Q, et al. 3D-printed graphene/polydimethylsiloxane composites for stretchable and strain-insensitive temperature sensors[J]. Applied Materials Interfaces, 2018, 11(1): 1344-1352. [76] MA Y N, YUE Y, ZHANG H, et al. 3D synergistical MXene/reduced graphene oxide aerogel for a piezoresistive sensor[J]. ACS Nano, 2018, 12(4): 3209-3216. doi: 10.1021/acsnano.7b06909 [77] LIU P F, LI X F, CHANG X Y, MIN P, et al. Highly anisotropic graphene aerogels fabricated by calcium ion-assisted unidirectional freezing for highly sensitive sensors and efficient cleanup of crude oil spills[J]. Carbon, 2021, 178: 301-309. doi: 10.1016/j.carbon.2021.03.014 [78] ZU G Q, KANAMORI K, NAKANISHI K, et al. Superhydrophobic ultraflexible triple-network graphene/polyorganosiloxane aerogels for a high-performance multifunctional temperature/strain/pressure sensing array[J]. Chemistry of Materials, 2019, 31(16): 6276-6285. doi: 10.1021/acs.chemmater.9b02437 [79] PENG X W, WU K Z, HU Y J, et al. A mechanically strong and sensitive CNT/rGO-CNF carbon aerogel for piezoresistive sensors[J]. Journal of Materials Chemistry A, 2018, 6(46): 23550-23559. doi: 10.1039/C8TA09322A [80] WANG M, CHEN Y L, QIN Y L, et al. Compressible, fatigue resistant, and pressure-sensitive carbon aerogels developed with a facile method for sensors and electrodes[J]. ACS Sustainable Chemistry of Engineering, 7(15): 12726-12733. [81] YU Z L, QIN B, MA Z Y, et al. Superelastic hard carbon nanofiber aerogels[J]. Advanced Materials, 2019, 31(23): 1900651. doi: 10.1002/adma.201900651 [82] WANG L, ZHANG M Y, YANG B, et al. Flexible, robust, and durable aramid fiber/CNT composite paper as a multifunctional sensor for wearable applications[J]. ACS Applied Materials & Interfaces, 2021, 13(4): 5486-5497. [83] CHEN X Y, LIU H, ZHENG Y J, et al. Highly compressible and robust polyimide/carbon nanotube composite aerogel for high-performance wearable pressure sensor[J]. ACS Applied Materials & Interfaces, 2019, 11(45): 42594-42606. [84] YANG M, ZHAO N F, CUI Y, et al. Biomimetic architectured graphene aerogel with exceptional strength and resilience[J]. ACS Nano, 2017, 11(7): 6817-6824. doi: 10.1021/acsnano.7b01815 [85] ZHANG Y N, MAO T Y, WU H, et al. Carbon nanotubes grown on flax fabric as hierarchical all-carbon flexible electrodes for supercapacitors[J]. Advanced Materials Interfaces, 2017, 4(9): 1601123. doi: 10.1002/admi.201601123 [86] XU X, LI H, ZHANG Q Q, et al. Self-sensing, ultralight, and conductive 3D graphene/iron oxide aerogel elastomer deformable in a magnetic field[J]. ACS Nano, 2015, 9(4): 3969-3977. doi: 10.1021/nn507426u [87] LI C W, QIU L, ZHANG B Q, et al. Robust vacuum-/air-dried graphene aerogels and fast recoverable shape-memory hybrid foams[J]. Advanced Materials, 2016, 28(7): 1510-1516. doi: 10.1002/adma.201504317 [88] TABASSIAN R, KIM J, NGUYEN V H, et al. Functionally antagonistic hybrid electrode with hollow tubular graphene mesh and nitrogen-doped crumpled graphene for high-performance ionic soft actuators[J]. Advanced Functional Materials, 2018, 28(5): 1705714. doi: 10.1002/adfm.201705714 [89] SHAO L H, BIENER J, JIN H J, et al. Electrically tunable nanoporous carbon hybrid actuators[J]. Advanced Functional Materials, 2012, 22(14): 3029-3034. doi: 10.1002/adfm.201200245 [90] LI W B, LI F Y, LI H Z, SU M, et al. Flexible circuits and soft actuators by printing assembly of graphene[J]. ACS Applied Materials & Interfaces, 2016, 8(19): 12369-12376. [91] GANONYAN N, HE J, TENKIN A, et al. Ultralight monolithic magnetite aerogel[J]. Applied Materials Today, 2021, 22: 100955. doi: 10.1016/j.apmt.2021.100955 [92] ALIEV A E, OH J, KOZLOV M E, et al. Giant-stroke, superelastic carbon nanotube aerogel muscles[J]. Science, 2009, 323(5921): 1575-1578. doi: 10.1126/science.1168312 [93] QIU L, LIU D Y, WANG Y F, et al. Mechanically robust, electrically conductive and stimuli-responsive binary network hydrogels enabled by superelastic graphene aerogels[J]. Advanced Materials, 2014, 26(20): 3333-3337. doi: 10.1002/adma.201305359 [94] KIM K H, VURAL M, ISLAM M F. Single-walled carbon nanotube aerogel-based elastic conductors[J]. Advanced Materials, 2011, 23(25): 2865-2869. doi: 10.1002/adma.201100310 [95] ZHANG X T, SUI Z Y, XU B, et al. Mechanically strong and highly conductive graphene aerogel and its use as electrodes for electrochemical power sources[J]. Journal of Materials Chemistry, 2011, 21(18): 6494-6497. doi: 10.1039/c1jm10239g [96] XU Z, ZHANG Y, LI P G, et al. Strong, conductive, lightweight, neat graphene aerogel fibers with aligned pores[J]. ACS Nano, 2012, 6(8): 7103-7113. doi: 10.1021/nn3021772 [97] TANG G, JIANG Z G, LI X, et al. Three dimensional graphene aerogels and their electrically conductive composites[J]. Carbon, 2014, 77: 592-599. doi: 10.1016/j.carbon.2014.05.063 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号