Identification of Pipeline Inner Wall Geometry Based on the POD-RBF Method

-

摘要: 针对天然气、石油等管道内部被腐蚀问题,基于本征正交分解-径向基函数(POD-RBF)提出了一种管道内壁几何识别方法. 考虑静磁场并建立管道的简化有限元模型,构建变几何样本库,实现了POD-RBF对任意形状的响应预测. 该方法在降阶分析的同时避免了迭代过程中因几何的改变需反复求解刚度矩阵,在很大程度上提高了计算效率. 采用灰狼优化(GWO)算法对目标函数实施优化,避免了在变几何过程中灵敏度的求解. 算例结果显示,该文方法可高效准确地反演管道内壁的几何形状,即使在引入噪声后GWO算法仍具有较好的稳定性.

-

关键词:

- 管道内壁几何形状识别 /

- 降阶代理模型 /

- 本征正交分解 /

- 径向基函数 /

- 灰狼优化算法

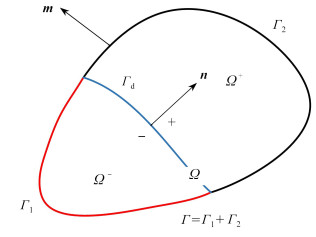

Abstract: Based on the proper orthogonal decomposition-radial basis function (POD-RBF), a geometric identification method for pipeline inner wall was proposed to solve the internal corrosion detection problem of natural gas and oil pipelines. In view of the static magnetic field, the simplified finite element model for the pipelines was established, and the variable-geometry sample library was constructed, to realize the response prediction of arbitrary geometry by the POD-RBF. The proposed method achieves reduced-order analysis and avoids repeated solution of the stiffness matrix due to the geometrical change during the identification process. Hence, it can significantly improve the computation efficiency. Finally, the grey wolf optimization (GWO) algorithm was used to optimize the objective function and avoid the calculation of the sensitivity in the process of geometry change. The numerical examples show that, the proposed method has high efficiency and accuracy in the geometric identification of the pipeline inner wall, with good stability even under introduced noises. -

表 1 识别结果

Table 1. The identified results

sample feature N=10 N=20 N=40 αp/m 0.532 89 0.532 98 0.533 01 absolute error Δαp/m 1.1×10-4 2.0×10-5 1.0×10-5 relative error δ/% 0.020 6 0.003 8 0.001 9 表 2 不同方案下的识别结果

Table 2. Identification results with different schemes

scheme real radius Rr/m identified radius Ri/m relative error δ/% 1 0.45 0.499 02 10.892 1 2 0.46 0.499 14 8.508 5 3 0.47 0.499 48 6.271 8 4 0.48 0.499 90 4.145 9 5 0.49 0.500 57 2.156 1 6 0.50 0.501 22 0.244 6 7 0.51 0.514 09 0.800 9 8 0.53 0.529 95 0.009 9 9 0.55 0.549 94 0.011 0 10 0.57 0.569 93 0.013 0 11 0.59 0.590 20 0.034 6 12 0.60 0.599 99 0.001 6 13 0.61 0.605 79 0.689 8 14 0.62 0.609 70 1.660 9 15 0.63 0.612 84 2.723 5 16 0.64 0.615 56 3.818 5 17 0.65 0.617 77 4.957 9 18 0.66 0.619 81 6.089 3 19 0.67 0.621 66 7.214 4 20 0.68 0.623 50 8.309 2 21 0.69 0.625 25 9.384 0 表 3 识别结果

Table 3. The identified results

error level δ/% the corresponding parameterαp/m 0 [0.525 41, 0.576 20, 0.524 89, 0.544 12, 0.514 53, 0.529 19, 0.529 58, 0.565 94, 0.486 45, 0.548 11, 0.530 33, 0.578 42]T 1 [0.546 53, 0.562 76, 0.541 14, 0.556 05, 0.541 27, 0.572 85, 0.537 73, 0.565 71, 0.520 06, 0.556 62, 0.545 09, 0.564 27]T 2 [0.534 33, 0.564 35, 0.542 28, 0.538 52, 0.550 63, 0.535 66, 0.548 13, 0.564 59, 0.509 82, 0.551 63, 0.532 63, 0.576 50]T 3 [0.530 88, 0.504 95, 0.513 75, 0.539 59, 0.534 85, 0.536 71, 0.550 55, 0.534 37, 0.550 73, 0.573 37, 0.563 28, 0.564 12]T -

[1] 丁舒婷, 唐建群, 巩建鸣. 含腐蚀缺陷油气管道适用性评价研究进展[J]. 机械制造与自动化, 2017, 46 (1): 226-229. https://www.cnki.com.cn/Article/CJFDTOTAL-ZZHD201701061.htmDING Shuting, TANG Jianqun, GONG Jianming. Overview of service ability assessment of oil and gas pipelines containing corrosives[J]. Machine Building & Automation, 2017, 46 (1): 226-229. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZZHD201701061.htm [2] 苑玮琦, 李绍丽, 李德健. 基于子区域变尺度高斯拟合的木材表面缺陷识别[J]. 仪器仪表学报, 2016, 37 (4): 879-886. doi: 10.3969/j.issn.0254-3087.2016.04.021YUAN Weiqi, LI Shaoli, LI Dejian. Wood surface defect recognition based on sub-region zoom Gaussian fitting[J]. Chinese Journal of Scientific Instrument, 2016, 37 (4): 879-886. (in Chinese) doi: 10.3969/j.issn.0254-3087.2016.04.021 [3] 孙彬, 王建华, 赫东锋, 等. 基于激光测量的航发叶片表面几何缺陷识别技术[J]. 自动化学报, 2020, 46 (3): 594-599. doi: 10.16383/j.aas.c180080SUN Bin, WANG Jianhua, HE Dongfeng, et al. Identification of aero-engine blade surface geometric defects with laser measurement[J]. Acta Automatica Sinica, 2020, 46 (3): 594-599. (in Chinese) doi: 10.16383/j.aas.c180080 [4] YU B, XU C, ZHOU H L, et al. A novel non-iterative method for estimating boundary conditions and geometry of furnace inner wall made of FGMs[J]. Applied Thermal Engineering, 2019, 147: 251-271. doi: 10.1016/j.applthermaleng.2018.10.075 [5] KIM H M, PARK G S. A study on the estimation of the shapes of axially oriented cracks in CMFL type NDT system[J]. IEEE Transactions on Magnetics, 2014, 50 (2): 109-112. doi: 10.1109/TMAG.2013.2283343 [6] VALLS M J, ULAPANE N, SHI L, et al. Robotic pipeline wall thickness evaluation for dense nondestructive testing inspection[J]. Journal of Field Robotics, 2018, 35 (8): 1293-1310. doi: 10.1002/rob.21828 [7] PENG X, ANYAOHA U, LIU Z, et al. Analysis of magnetic-flux leakage (MFL) data for pipeline corrosion assessment[J]. IEEE Transactions on Magnetics, 2020, 56 (6): 1-15. doi: 10.1109/TMAG.2020.2994477 [8] FISER R, FERKOLJ S. Application of a finite element method to predict damaged induction motor performance[J]. IEEE Transactions on Magnetics, 2001, 37 (5): 3635-3639. doi: 10.1109/20.952679 [9] QUÉVAL L, LIU K, YANG W J, et al. Superconducting magnetic bearings simulation using an H-formulation finite element model[J]. Superconductor Science and Technology, 2018, 31 (8): 084001. doi: 10.1088/1361-6668/aac55d [10] MOURAD A, AISSA A, MEBAREK-OUDINA F, et al. Galerkin finite element analysis of thermal aspects of Fe3O4-MWCNT/water hybrid nanofluid filled in wavy enclosure with uniform magnetic field effect[J]. International Communications in Heat and Mass Transfer, 2021, 126: 105461. doi: 10.1016/j.icheatmasstransfer.2021.105461 [11] BONABEAU E, DORIGO M, THERAULAZ G. Swarm Intelligence: From Natural to Artificial Systems[M]. Oxford: Oxford University Press, 1999. [12] GANDOMI A H, YANG X S, ALAVI A H. Cuckoo search algorithm: a metaheuristic approach to solve structural optimization problems[J]. Engineering With Computers, 2013, 29 (1): 17-35. doi: 10.1007/s00366-011-0241-y [13] DORIGO M, BIRATTARI M, STUTZLE T. Ant colony optimization[J]. IEEE Computational Intelligence Magazine, 2006, 1 (4): 28-39. doi: 10.1109/MCI.2006.329691 [14] 金树, 任宗栋, 李宏男, 等. 输电塔结构离散变量优化设计方法[J]. 工程力学, 2016, 33 (11): 84-94. doi: 10.6052/j.issn.1000-4750.2015.02.0102JIN Shu, REN Zongdong, LI Hongnan, et al. Discrete variable optimal design method of transmission tower structure[J]. Engineering Mechanics, 2016, 33 (11): 84-94. (in Chinese) doi: 10.6052/j.issn.1000-4750.2015.02.0102 [15] KENNEDY J, EBERHART R. Particle swarm optimization[C]//Proceedings of ICNN' 95 -International Conference on Neural Networks. Perth, Australia, 1995, 4: 1942-1948. [16] 夏志远, 李爱群, 李建慧, 等. 基于GMPSO的有限元模型修正方法验证[J]. 工程力学, 2019, 36 (10): 66-74. https://www.cnki.com.cn/Article/CJFDTOTAL-GCLX201910009.htmXIA Zhiyuan, LI Aiqun, LI Jianhui, et al. Validation of finite element model updating methodology based on GMPSO[J]. Engineering Mechanics, 2019, 36 (10): 66-74. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GCLX201910009.htm [17] MIRJALILI S, MIRJALILI S M, LEWIS A. Grey wolf optimizer[J]. Advances in Engineering Software, 2014, 69: 46-61. doi: 10.1016/j.advengsoft.2013.12.007 [18] 余波, 孙文涧. 基于比例边界有限元法和灰狼优化算法的裂纹尖端位置识别[J]. 应用数学和力学, 2021, 42 (11): 1177-1189. doi: 10.21656/1000-0887.410381YU Bo, SUN Wenjian. Identification of crack tip positions based on the scaled boundary finite element method and the grey wolf optimization algorithm[J]. Applied Mathematics and Mechanics, 2021, 42 (11): 1177-1189. (in Chinese) doi: 10.21656/1000-0887.410381 [19] KOHLI M, ARORA S. Chaotic grey wolf optimization algorithm for constrained optimization problems[J]. Journal of Computational Design and Engineering, 2018, 5 (4): 458-472. doi: 10.1016/j.jcde.2017.02.005 [20] 张晓凤, 王秀英. 灰狼优化算法研究综述[J]. 计算机科学, 2019, 46 (3): 30-38. https://www.cnki.com.cn/Article/CJFDTOTAL-JSJA201903004.htmZHANG Xiaofeng, WANG Xiuying. Comprehensive review of grey wolf optimization algorithm[J]. Computer Science, 2019, 46 (3): 30-38. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JSJA201903004.htm [21] 蒋耀林. 模型降阶方法[M]. 北京: 科学出版社, 2010.JIANG Yaolin. Model Order Reduction Method[M]. Beijing: Science Press, 2010. (in Chinese) [22] HELLSTRÖM L H O, SMITS A J. Structure identification in pipe flow using proper orthogonal decomposition[J]. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 2017, 375 (2089): 20160086. doi: 10.1098/rsta.2016.0086 [23] EFTEKHAR AZAM S, RAGEH A, LINZELL D. Damage detection in structural systems utilizing artificial neural networks and proper orthogonal decomposition[J]. Structural Control and Health Monitoring, 2019, 26 (2): e2288. doi: 10.1002/stc.2288 [24] BOX G E P, WILSON K B. On the Experimental Attainment of Optimum Conditions[M]. New York: Springer, 1992. [25] KLEIJNEN J P C. Regression and Kriging metamodels with their experimental designs in simulation: a review[J]. European Journal of Operational Research, 2017, 256 (1): 1-16. doi: 10.1016/j.ejor.2016.06.041 [26] STEIN M L. Interpolation of Spatial Data: Some Theory for Kriging[M]. New York: Springer, 1999. [27] XIAO M, ZHANG J H, GAO L. A system active learning Kriging method for system reliability-based design optimization with a multiple response model[J]. Reliability Engineering & System Safety, 2020, 199: 106935. [28] BUHMANN M D. Radial Basis Functions: Theory and Implementations[M]. Cambridge: Cambridge University Press, 2003. [29] SONG X G, LV L Y, SUN W, et al. A radial basis function-based multi-fidelity surrogate model: exploring correlation between high-fidelity and low-fidelity models[J]. Structural and Multidisciplinary Optimization, 2019, 60 (3): 965-981. doi: 10.1007/s00158-019-02248-0 [30] 潘兆东, 刘良坤, 谭平, 等. 大型结构自适应学习率RBF神经网络滑模分散控制研究[J]. 工程力学, 2019, 36 (9): 120-127. https://www.cnki.com.cn/Article/CJFDTOTAL-GCLX201909015.htmPAN Zhaodong, LIU Liangkun, TAN Ping, et al. Research on sliding mode decentralized control based on adaptive learning rate RBF neural network for large-scale engineering structures[J]. Engineering Mechanics, 2019, 36 (9): 120-127. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GCLX201909015.htm [31] VANLUCHENE R D, SUN R. Neural networks in structural engineering[J]. Computer-Aided Civil and Infrastructure Engineering, 1990, 5 (3): 207-215. doi: 10.1111/j.1467-8667.1990.tb00377.x [32] HAN X, XIANG H Y, LI Y L, et al. Predictions of vertical train-bridge response using artificial neural network-based surrogate model[J]. Advances in Structural Engineering, 2019, 22 (12): 2712-2723. doi: 10.1177/1369433219849809 [33] YU B, CAO G Y, REN S H, et al. An isogeometric boundary element method for transient heat transfer problems in inhomogeneous materials and the non-iterative inversion of loads[J]. Applied Thermal Engineering, 2022, 212: 118600. doi: 10.1016/j.applthermaleng.2022.118600 [34] 余波, 吴月, 聂川宝, 等. 动载荷识别的非迭代法研究[J]. 应用数学和力学, 2019, 40 (5): 473-489. doi: 10.21656/1000-0887.390211YU Bo, WU Yue, NIE Chuanbao, et al. A non-iterative method for dynamic load identification[J]. Applied Mathematics and Mechanics, 2019, 40 (5): 473-489. (in Chinese) doi: 10.21656/1000-0887.390211 [35] JIN R, CHEN W, SIMPSON T W. Comparative studies of metamodelling techniques under multiple modelling criteria[J]. Structural and Multidisciplinary Optimization, 2001, 23 (1): 1-13. doi: 10.1007/s00158-001-0160-4 [36] JING Z, CHEN J, LI X. RBF-GA: an adaptive radial basis function metamodeling with genetic algorithm for structural reliability analysis[J]. Reliability Engineering & System Safety, 2019, 189: 42-57. [37] LIU X, LIU X, ZHOU Z H, et al. An efficient multi-objective optimization method based on the adaptive approximation model of the radial basis function[J]. Structural and Multidisciplinary Optimization, 2021, 63 (3): 1385-1403. doi: 10.1007/s00158-020-02766-2 [38] KHATIR S, WAHAB M A. Fast simulations for solving fracture mechanics inverse problems using POD-RBF XIGA and Jaya algorithm[J]. Engineering Fracture Mechanics, 2019, 205: 285-300. doi: 10.1016/j.engfracmech.2018.09.032 [39] HENNERON T, PIERQUIN A, CLENET S. Surrogate model based on the POD combined with the RBF interpolation of nonlinear magnetostatic FE model[J]. IEEE Transactions on Magnetics, 2019, 56 (1): 1-4. [40] WANG S, KHATIR S, WAHAB M A. Proper orthogonal decomposition for the prediction of fretting wear characteristics[J]. Tribology International, 2020, 152: 106545. doi: 10.1016/j.triboint.2020.106545 [41] 金建铭. 电磁场有限元方法[M]. 西安: 西安电子科技大学出版社, 1998.JIN Jianming. Finite Element Method of Electromagnetic Field[M]. Xi'an: Xidian Electronic University Press, 1998. (in Chinese) [42] 钱丽佳. 深海油气输送管道的缺陷定位与识别研究[D]. 硕士学位论文. 天津: 天津大学, 2017.QIAN Lijia. Research on the localization and identification of defects of deep sea oil and gas pipeline[D]. Master Thesis. Tianjin: Tianjin University, 2017. (in Chinese) [43] WANG G G. Adaptive response surface method using inherited Latin hypercube design points[J]. Journal of Mechanical Design, 2003, 125 (2): 210-220. doi: 10.1115/1.1561044 [44] NIE C B, YU B. Inversing heat flux boundary conditions based on precise integration FEM without iteration and estimation of thermal stress in FGMs[J]. International Journal of Thermal Sciences, 2019, 140: 201-224. doi: 10.1016/j.ijthermalsci.2019.03.003 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号