Three-Level Safety Evaluation of Suspended Sections of Underwater Buried Pipelines

-

摘要:

水下穿越管道由于河床的不平整以及水流冲击、掏蚀作用,易产生裸露 、悬空等现象,悬空管段在水流作用下跨度逐渐增大,会威胁管道运营安全。为探究水流冲击作用下悬空管段的受力特性和失效行为,根据管道破坏形式,对管道进行静力学分析和动力学分析,提出了含悬空段穿越管道的分级安全评价方法:首先,根据管道悬空段受力特性和应力状态,进行“静载荷工况下的静强度安全评价”(1级);其次,根据悬空管道的固有振动频率与水流的涡旋发放频率的关系,进行“动载荷工况下的共振安全评价”(2级);最后,根据管道的环境工况和载荷作用,分析管道交变应力的周期性变化过程,求解管道的疲劳损伤和疲劳寿命,进行“动载荷工况下的疲劳强度安全评价”(3级),从而提出水下穿越管道悬空段的三级安全评价方法。同时,提出了不满足安全评价的稳管措施,结合算例给出具体求解计算流程,为水下穿越管道悬空段的安全评价提供了一定的理论参考。

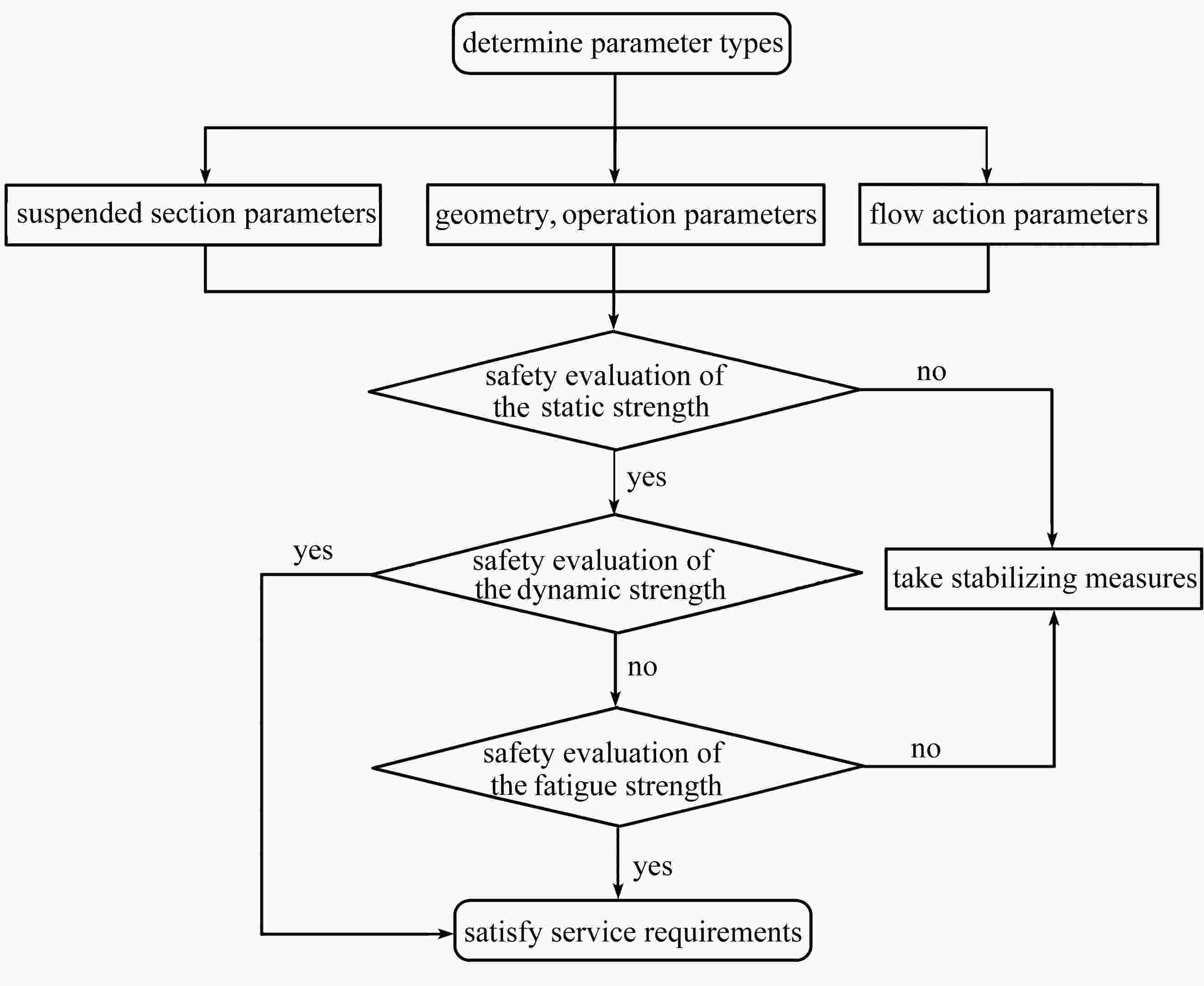

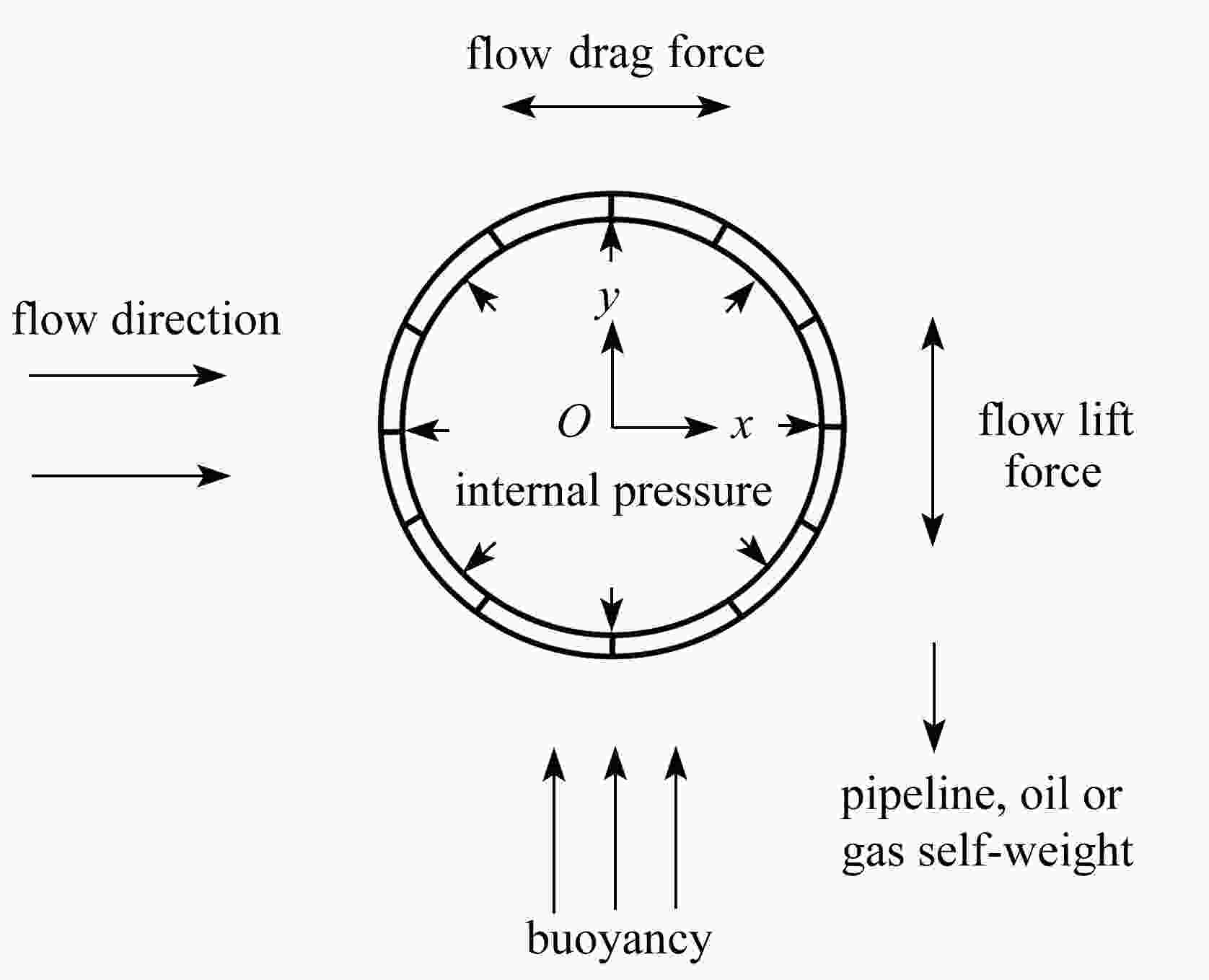

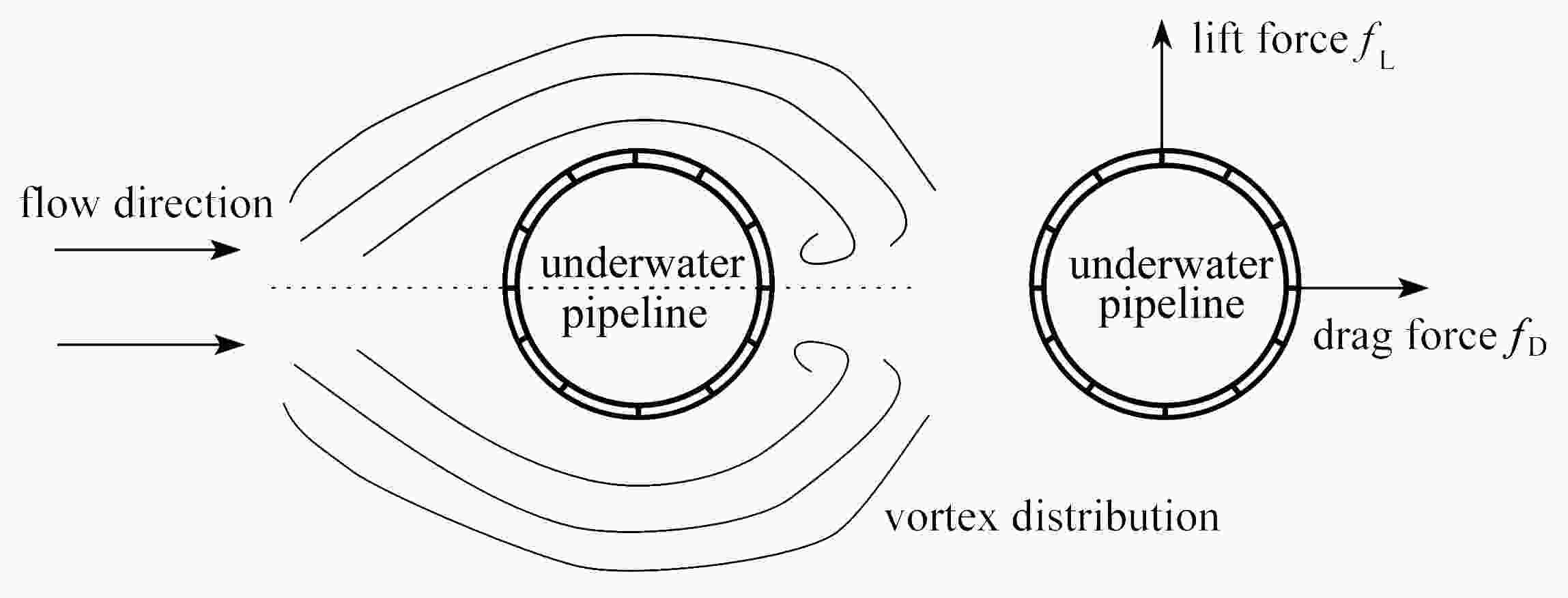

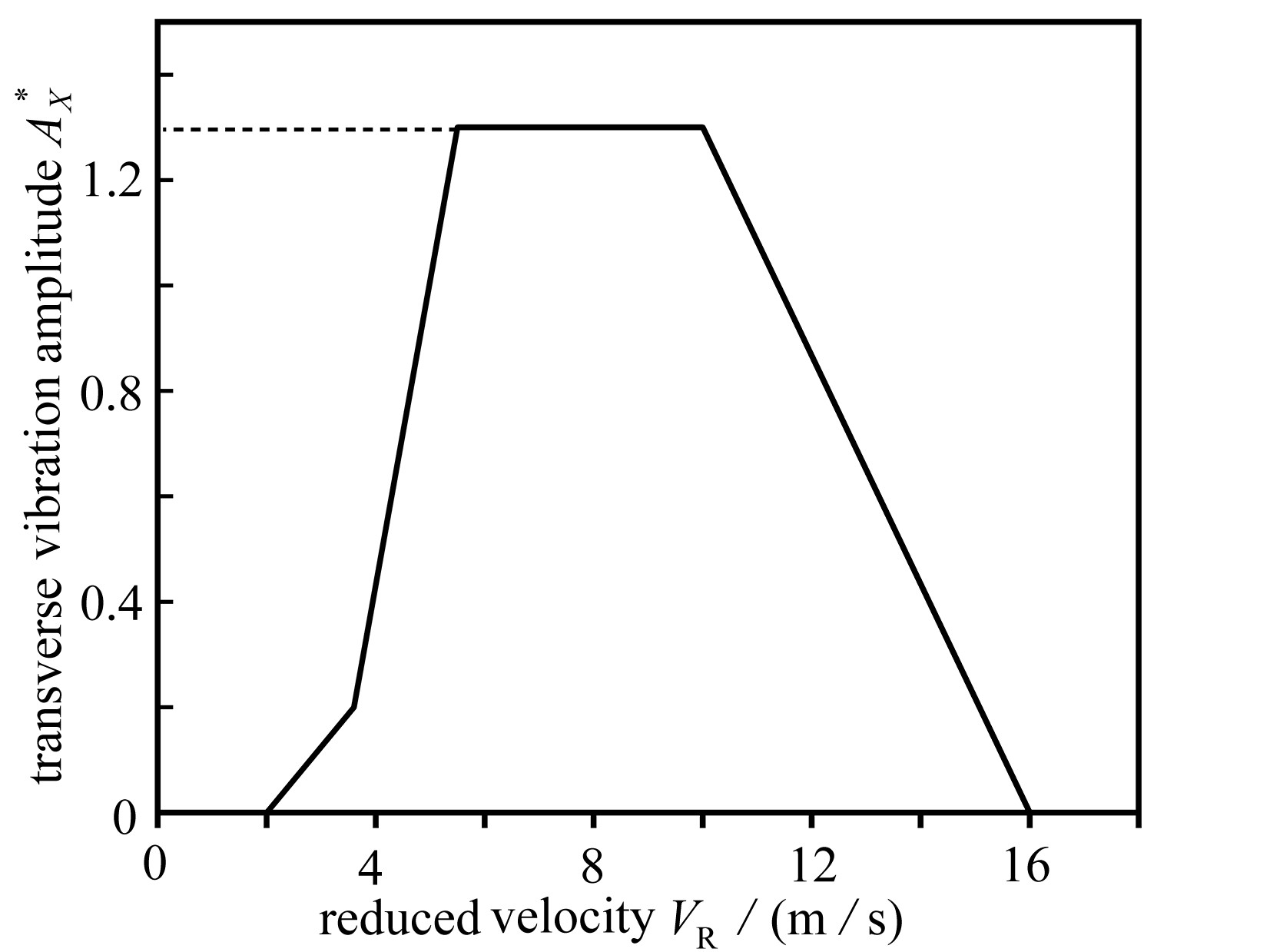

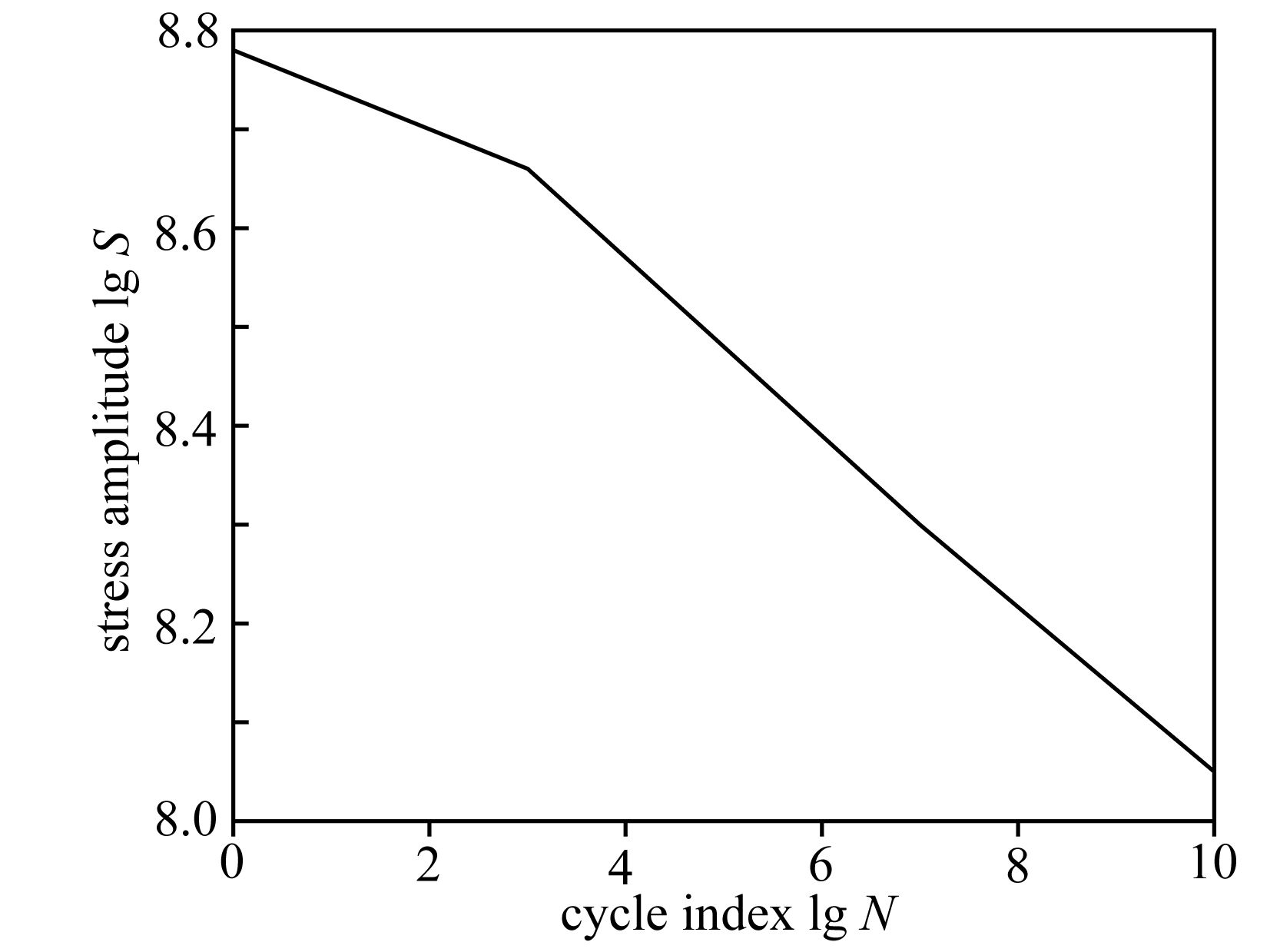

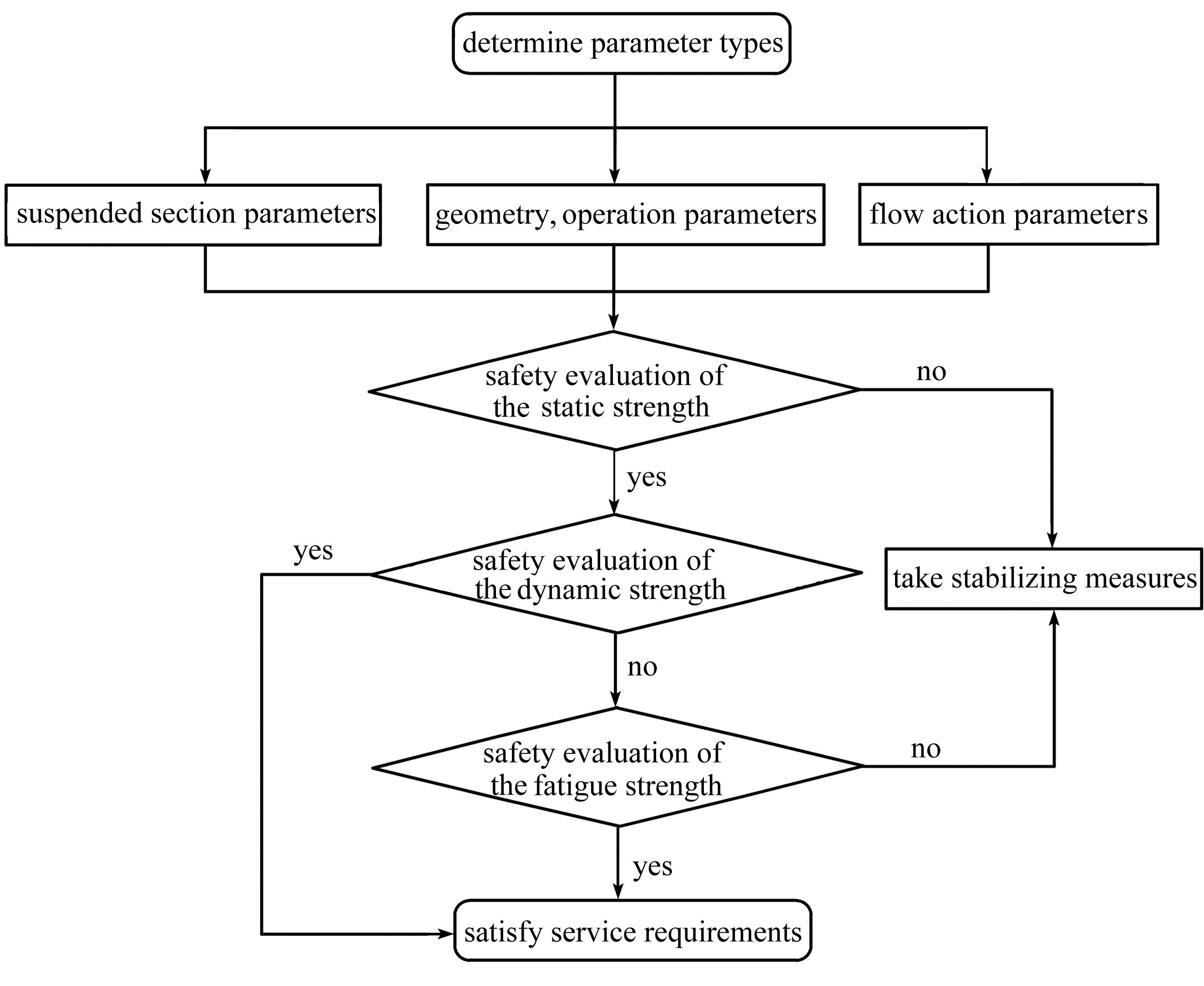

Abstract:The uneven riverbed, and the impact and scour actions by water flow, make the underwater buried pipeline vulnerable to exposure and suspension, and endanger the pipeline operation safety. To investigate the mechanical properties and failure behaviors of the suspended pipeline section under water impact, according to the failure mechanism of the pipeline, the statics and dynamics analyses of the pipeline were carried out, and the graded safety evaluation technique for the buried pipeline with suspended sections was presented. First, a “static strength safety evaluation under static loads” (level 1) was conducted according to the mechanical features and stress states of the pipeline’s suspended section. Second, a “resonance safety evaluation under dynamic loads” (level 2) was conducted based on the correlation between the natural vibration frequencies of the suspended pipeline and the vortex emission frequencies of water flow. Finally, the periodical change process of the pipeline’s alternating stress was studied to solve the fatigue damage and fatigue life of the pipeline, and the “fatigue strength safety evaluation under dynamic loads” (level 3) was performed. Thus, a 3-level safety assessment procedure for pipelines with suspended sections was proposed. The stabilizing measures for pipelines of poor safety were suggested, and through an example, a specific calculation process was provided. The work serves as a theoretical guide for the safety evaluation of the suspended sections of underwater buried pipelines.

-

-

[1] 王蒙蒙. 基于DNV规范的海底管线悬跨分析[D]. 硕士学位论文. 天津: 天津大学, 2014.WANG Mengmeng. Submarine pipeline span analysis based on DNV standard[D]. Master Thesis. Tianjin: Tianjin University, 2014. (in Chinese) [2] 李亮亮, 朱洁, 韩冰. 穿越河流管道悬跨安全长度判定[J]. 长江科学院院报, 2014, 31(2): 86-90LI Liangliang, ZHU Jie, HAN Bing. Determining the safety length of suspended span of river-crossing pipelines[J]. Journal of Yangtze River Scientific Research, 2014, 31(2): 86-90.(in Chinese) [3] 谢英, 麻秀芬, 宁海峰. 海底悬跨管道形成及破坏机理[J]. 油气储运, 2017, 36(12): 1436-1442XIE Yin, MA Xiufen, NING Haifeng. Formation and damage mechanism of free spanning submarine pipeline[J]. Oil & Gas Storage and Transportation, 2017, 36(12): 1436-1442.(in Chinese) [4] 袁嘉瑞, 丁虎, 陈立群. 微曲输流管道振动固有频率分析与仿真[J]. 应用数学和力学, 2022, 43(7): 719-726YUAN Jiarui, DING Hu, CHEN Liqun. Analysis and simulation of natural frequencies of slightly curved pipes[J]. Applied Mathematics and Mechanics, 2022, 43(7): 719-726.(in Chinese) [5] PARK H I, KIM C H. Analytical methods for the determination of allowable free span lengths[C]//Proceedings of the 7th International Offshore and Polar Engineering Conference. Honolulu, Hawaii, USA, 1997. [6] KANTARDGI I G, GOGIN A G. Submarine pipeline stability under stream and waves action[J]. Power Technology and Engineering, 2021, 55(3): 367-372. doi: 10.1007/s10749-021-01366-4 [7] XU W H, JIA K, MA Y, et al. Multispan classification methods and interaction mechanism of submarine pipelines undergoing vortex-induced vibration[J]. Applied Ocean Research, 2022, 120: 103027. doi: 10.1016/j.apor.2021.103027 [8] CHOI H S. Free spanning analysis of offshore pipelines[J]. Ocean Engineering, 2001, 28(10): 1325-1338. doi: 10.1016/S0029-8018(00)00071-8 [9] 张凯凯, 谭霞, 丁虎, 等. 超临界输流管道3∶1内共振下参激振动响应[J]. 应用数学和力学, 2018, 39(11): 1227-1235ZHANG Kaikai, TAN Xia, DING Hu, et al. Parametric vibration responses of supercritical fluid-conveying pipes in 3∶1 internal resonance[J]. Applied Mathematics and Mechanics, 2018, 39(11): 1227-1235.(in Chinese) [10] 黄小光, 韩忠英. 海底管道疲劳损伤与疲劳寿命的可靠性计算[J]. 油气储运, 2010, 29(11): 827-831HUANG Xiaoguang, HAN Zhongying. Reliability calculation of fatigue damage and fatigue life of submarine pipeline[J]. Oil & Gas Storage and Transportation, 2010, 29(11): 827-831.(in Chinese) [11] YTTERVIK R, LARSEN C M, FUMES G K. Fatigue from vortex-induced vibrations of free span pipelines using stafisfics of current speed and direction[C]//Proceedings of OMAE. Cancun, Mexico, 2003: 687-698. [12] 向敏, 刁洪涛, 张子涛, 等. 水下穿越油气管道水流冲击作用下强度安全研究[J]. 工业安全与环保, 2017, 43(5): 66-68 doi: 10.3969/j.issn.1001-425X.2017.05.020XIANG Ming, DIAO Hongtao, ZHANG Zitao, et al. Study on strengthen safety of oil and gas pipelines under the impact of water flow[J]. Industrial Safety and Environmental Protection, 2017, 43(5): 66-68.(in Chinese) doi: 10.3969/j.issn.1001-425X.2017.05.020 [13] 杨庆华, 张宇倩, 杨乾, 等. 水下穿越管道悬空段受力特性的试验研究[J]. 工程科学与技术, 2021, 53(2): 19-27YANG Qinghua, ZHANG Yuqian, YANG Qian, et al. Experimental study on the loading capacity of suspended section of underwater crossing pipeline[J]. Advanced Engineering Sciences, 2021, 53(2): 19-27.(in Chinese) [14] 柳军, 郭晓强, 刘清友, 等. 考虑顺流向和横流向耦合作用的海洋立管涡激振动响应特性[J]. 石油学报, 2019, 40(10): 1270-1280 doi: 10.7623/syxb201910012LIU Jun, GUO Xiaoqiang, LIU Qinyou, et al. Vortex induced vibration response characteristics of marine riser considering the in-line and cross flow coupling effect[J]. Acta Petrolei Sinica, 2019, 40(10): 1270-1280.(in Chinese) doi: 10.7623/syxb201910012 [15] 申国兵. 考虑管土作用的海底多跨管道振动特性研究[D]. 硕士学位论文. 天津: 天津大学, 2015.SHEN Guobin. Vibration characteristics of subsea multi-span pipe considering pipe-soil interaction[D]. Master Thesis. Tianjin: Tianjin University, 2015. (in Chinese) [16] 恽秋琴, 艾尚茂, 孙丽萍. 海底多跨管道涡激振动疲劳简化分析[J]. 中国造船, 2010, 51(4): 111-117YUN Qiuqin, AI Shangmao, SUN Liping. Simplified fatigue analysis on the vortex induced vibration of the multi-spanning subsea pipeline[J]. Shipbuilding of China, 2010, 51(4): 111-117.(in Chinese) -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号