A Study on the Fatigue Life of the Laser Additive Manufactured Metallic Material

-

摘要:

随着军用飞机上越来越多的结构件使用增材制造(AM)技术成形,对增材制造材料和结构疲劳特性的研究就变得十分迫切。为了研究激光增材制造(选区激光熔化成形,SLM)铝合金以及钛合金的疲劳寿命特性,设计了一系列带各种结构细节的模拟试验件,进行常幅谱和随机谱下的试验,统计分析了各组试验的基本可靠性寿命,并得到了可靠度安全寿命曲线。断口分析发现铝合金试验件缺陷较多,存在混合失效特征,而钛合金试验件疲劳分散性较锻件大。

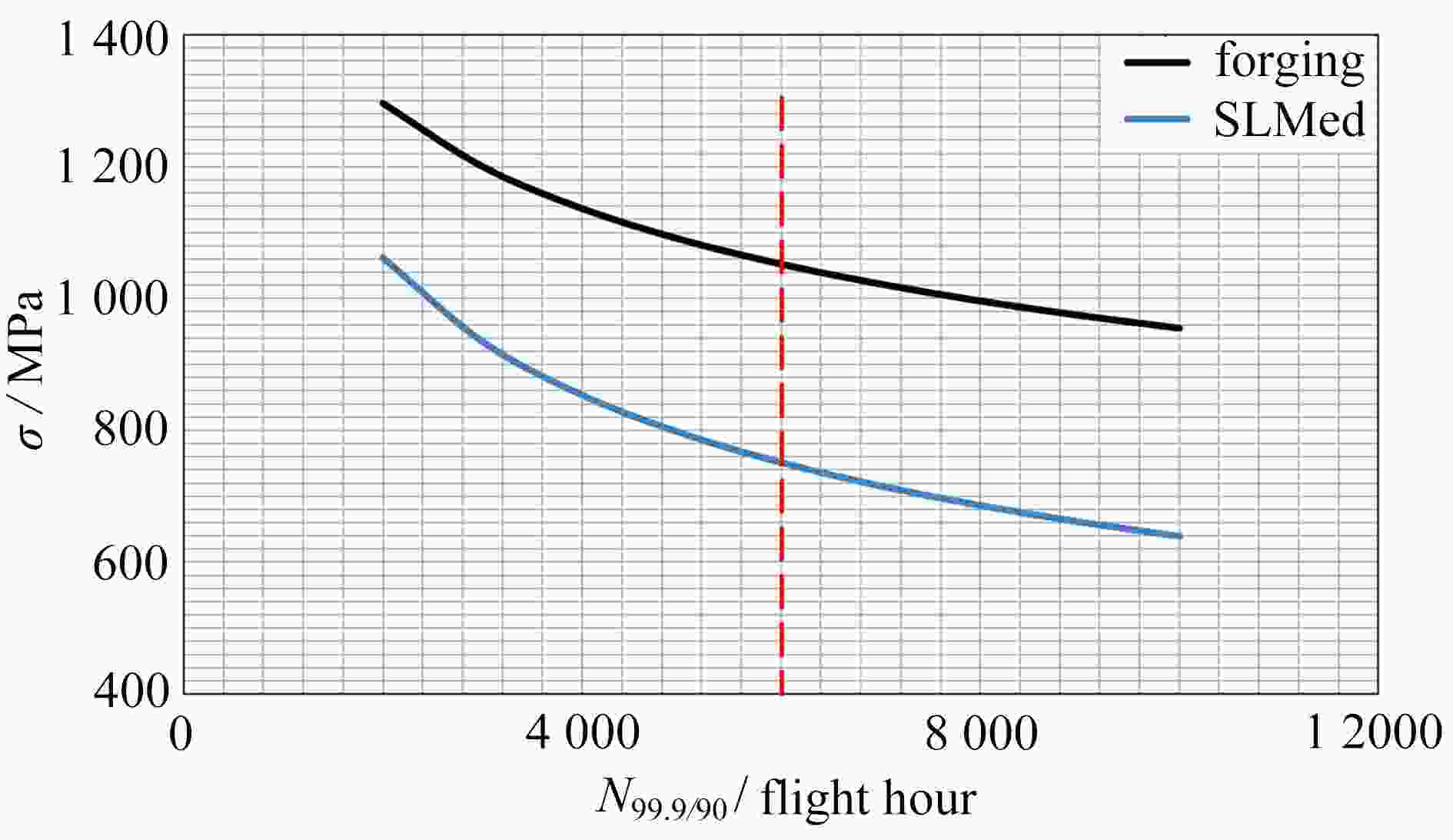

Abstract:As more and more structural parts of military aircraft are formed with the additive manufacturing (AM) technology, it is very urgent to study the fatigue characteristics of the additive manufactured materials and structures. To investigate the fatigue life characteristics of the aluminum alloy and the titanium alloy manufactured with the selective laser melting (SLM) technology, a series of specimens with various structural details were designed and tested under the constant amplitude spectrum and the random spectrum. The basic reliable life of each test specimen was statistically analyzed and the reliable safety life curve was obtained. The fractography analysis shows that, more defects and mixed failure characteristics exist in the aluminum alloy specimens, while the fatigue scatter of the titanium alloy specimens is larger than that of forge pieces.

-

表 1 AlSi10Mg粉末和TC4 ELI粉末的主要化学成分

Table 1. Main chemical compositions of the AlSi10Mg powder and the TC4 ELI powder

AlSi10Mg element Al Si Mg Fe Mn Ti mass fraction balance 9.0% ~ 11.0% 0.2% ~ 0.5% < 0.55% < 0.45% < 0.15% TC4 ELI ellement Ti V Al Sn Mo Cu Mn mass fraction balance 3.4% ~ 4.5% 5.5% ~ 6.5% < 0.1% < 0.1% < 0.1% < 0.1% no more than 0.2% in total 表 2 试验矩阵

Table 2. The test matrix

material specimen test spectrum structural detail AlSi10Mg type 1 constant amplitude/ LT=20% type 3 random spectrum Kt=1.37 TC4 ELI type 2 constant amplitude/ LT=20% type 4 random spectrum Kt=5.10 表 3 试验结果

Table 3. Test results

AlSi10Mg TC4 ELI specimen σmax/MPa N99.9/90 specimen σmax/MPa N99.9/90 constant amplitude spectrum (N99.9/90 in cycles) type 1 121 35 635 type 2 314 47 214 110 76 232 280 84 662 type 3 200 44 799 type 4 607 23 346 196 42 044 552 39 926 random spectrum (N99.9/90 in flight hour) type 1 171 1 683 type 2 572 2 924 155 5 461 520 4 563 140 7 449 468 8 238 type 3 252 2 629 type 4 933 2 959 230 5 281 877 4 205 220 7 282 786 5 239 表 4 拟合结果

Table 4. Fitting results

material specimen structural detail fitting equation AlSi10Mg type 1 LT=20% σ7.334= 5×1019 N type 3 Kt=1.37 σ7.522= 3×1021 N TC4 ELI type 2 LT=20% σ5.170= 5×1017 N type 4 Kt=5.10 σ3.173= 8×1012 N 表 5 试件1疲劳分散性对比

Table 5. Comparison of fatigue scatter for specimen type 1

material AlSi10Mg 7475-T7351 7050-T7651 logarithmic standard deviation 0.116 0.115 0.201 0.116 0.230 0.117 0.167 0.131 0.209 average 0.133 0.159 0.176 表 6 试件4疲劳分散性对比

Table 6. Comparison of the fatigue scatter for specimen type 4

material spectrum σmax/MPa number fatigue life (cycles) number of defects TC4 ELI constant amplitude 524 05 >100 0000 0 08 >400 000 (uncracked) 4 09 72 000 5 13 36 000 0 表 7 试验件断口反推结果

Table 7. The inference results from the fractography of the specimens

specimen material total life (cycles) life of crack initiation (cycles) life of crack growth (cycles) growth life to total life fig. 5(a) AlSi10Mg 115 000 108 000 7 000 6.10% fig. 5(c) TC4 ELI 455 000 437 000 18 000 4.00% -

[1] 王向明, 苏亚东, 吴斌. 增材技术在飞机结构研制中的应用[J]. 航空制造技术, 2014, 57(22): 16-20WANG Xiangming, SU Yadong, WU bin. Application of additive manufacturing technology on aircraft structure development[J]. Aeronautical Manufacturing Technology, 2014, 57(22): 16-20.(in Chinese) [2] 苏亚东, 吴斌, 王向明. 增材制造技术在航空装备深化应用中的研究[J]. 航空制造技术, 2016, 59(12): 42-48SU Yadong, WU bin, WANG Xiangming. Research on further application of additive manufacturing technology on aviation equipment[J]. Aeronautical Manufacturing Technology, 2016, 59(12): 42-48.(in Chinese) [3] 张学军, 唐思熠, 肇恒跃, 等. 3D打印技术研究现状和关键技术[J]. 材料工程, 2016, 44(2): 122-128 doi: 10.11868/j.issn.1001-4381.2016.02.019ZHANG Xuejun, TANG Siyi, ZHAO Hengyue, et al. Research status and key technologies of 3D printing[J]. Journal of Materials Engineering, 2016, 44(2): 122-128.(in Chinese) doi: 10.11868/j.issn.1001-4381.2016.02.019 [4] 王华明. 高性能大型金属构件激光增材制造: 若干材料基础问题[J]. 航空学报, 2014, 35(10): 2690-2698WANG Huaming. Materials’ fundamental issues of laser additive manufacturing for high-performance large metallic components[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(10): 2690-2698.(in Chinese) [5] 林鑫, 黄卫东. 高性能金属构件的激光增材制造[J]. 中国科学:信息科学, 2015, 45(9): 1111-1126 doi: 10.1360/N112014-00245LIN Xin, HUANG Weidong. Laser additive manufacturing of high-performance metal components[J]. Scientia Sinica Informationis, 2015, 45(9): 1111-1126.(in Chinese) doi: 10.1360/N112014-00245 [6] 潘新, 张英伟, 刘艳梅, 等. 金属增材制造技术应用于军用飞机维修保障浅析[J]. 航空制造技术, 2021, 64(3): 34-43PAN Xin, ZHANG Yingwei, LIU Yanmei, et al. Applications of metal additive manufacturing technology in maintenance and support for military aircraft[J]. Aeronautical Manufacturing Technology, 2021, 64(3): 34-43.(in Chinese) [7] 杨占尧, 赵敬云. 增材制造与3D打印技术及应用[M]. 北京: 清华大学出版社, 2017: 69-70.YANG Zhanyao, ZHAO Jingyun. Additive Manufacturing and 3D Printing Technology and Application[M]. Beijing: Tsinghua University Press, 2017: 69-70. (in Chinese) [8] 顾冬冬, 张红梅, 陈洪宇, 等. 航空航天高性能金属材料构件激光增材制造[J]. 中国激光, 2020, 47(5): 0500002 doi: 10.3788/CJL202047.0500002GU Dongdong, ZHANG Hongmei, CHEN Hongyu, et al. Laser additive manufacturing of high-performance metallic aerospace components[J]. Chinese Journal of Lasers, 2020, 47(5): 0500002.(in Chinese) doi: 10.3788/CJL202047.0500002 [9] 常坤, 梁恩泉, 张韧, 等. 金属材料增材制造及其在民用航空领域的应用研究现状[J]. 材料导报, 2021, 35(3): 3176-3182 doi: 10.11896/cldb.19100153CHANG Kun, LIANG Enquan, ZHANG Ren, et al. Status of metal additive manufacturing and its application research in the field of civil aviation[J]. Materials Reports, 2021, 35(3): 3176-3182.(in Chinese) doi: 10.11896/cldb.19100153 [10] 邹田春, 陈敏英, 祝贺, 等. 激光选区熔化AlSi7Mg合金高周疲劳性能研究[J]. 激光与光电子学进展, 2020, 57(23): 234-241ZHOU Tianchun, CHEN Minying, ZHU He, et al. Research on high cycle fatigue performance of AlSi7Mg alloy fabricated by selective laser melting[J]. Laser and Optoelectronics Progress, 2020, 57(23): 234-241.(in Chinese) [11] 孙文博, 马玉娥. 选区激光熔化TC4钛合金疲劳裂纹扩展行为研究[J]. 航空科学技术, 2022, 33(3): 71-76SUN Wenbo, MA Yu’e. Research on fatigue crack growth behavior of selective laser melted TC4 titanium alloy[J]. Aeronautics Science & Technology, 2022, 33(3): 71-76.(in Chinese) [12] 张继奎, 孔祥艺, 马少俊, 等. 激光增材制造高强高韧TC11钛合金力学性能及航空主承力结构应用分析[J]. 航空学报, 2021, 42(10): 525430ZHANG Jikui, KONG Xiangyi, MA Shaojun, et al. Laser additive manufactured high strength-toughness TC11 titanium alloy: mechanical properties and application in airframe load-bearing structure[J]. Acta Aeronautica et Astronautica Sinica, 2021, 42(10): 525430.(in Chinese) [13] 肖来荣, 谭威, 刘黎明, 等. 激光增材制造GH3536合金的低周疲劳行为[J]. 中国激光, 2021, 48(22): 2202009 doi: 10.3788/CJL202148.2202009XIAO Lairong, TAN Wei, LIU Liming, et al. Low cycle fatigue behavior of GH3536 alloy formed via laser additive manufacturing[J]. Chinese Journal of Lasers, 2021, 48(22): 2202009.(in Chinese) doi: 10.3788/CJL202148.2202009 [14] 薛志远. 选区激光熔化Inconel 625疲劳裂纹扩展行为研究[D]. 硕士学位论文. 南昌: 南昌航空大学, 2019.XUE Zhiyuan. Fatigue crack growth behavior of a selective laser melting Inconel 625[D]. Master Thesis. Nanchang: Nanchang Hangkong University, 2019. (in Chinese) [15] 李亚, 易志坚, 王敏, 等. 裂纹面局部均布荷载下Ⅰ型裂纹有限宽板应力强度因子[J]. 应用数学和力学, 2020, 41(10): 538-546LI Ya, YI Zhijian, WANG Min, et al. The stress intensity factor of a finite-width plate with a mode-Ⅰ center crack subjected to uniform stress on the crack surface near the crack tip[J]. Applied Mathematics and Mechanics, 2020, 41(10): 538-546.(in Chinese) [16] 万华亮, 王奇志. 增材制造铝镁合金AlSi10Mg的疲劳性能研究[J]. 强度与环境, 2019, 46(3): 20-26 doi: 10.19447/j.cnki.11-1773/v.2019.03.004WAN Hualiang, WANG Qizhi. Research on the fatigue behavior of additive manufacture materials of AlSi10Mg[J]. Structure & Environment Engineering, 2019, 46(3): 20-26.(in Chinese) doi: 10.19447/j.cnki.11-1773/v.2019.03.004 [17] 刘建涛, 杜平安, 黄明镜, 等. 结构疲劳长裂纹扩展速率新模型研究[J]. 应用数学和力学, 2009, 30(5): 538-546 doi: 10.3879/j.issn.1000-0887.2009.05.004LIU Jiantao, DU Ping’an, HUANG Mingjing, et al. Research on new model of long fatigue crack propagation rates for structures[J]. Applied Mathematics and Mechanics, 2009, 30(5): 538-546.(in Chinese) doi: 10.3879/j.issn.1000-0887.2009.05.004 [18] 彭梦瑶, 顾水涛, 周洋靖, 等. 基于LiToSim平台的疲劳寿命评估LtsFatigue软件开发及应用[J]. 应用数学和力学, 2022, 43(9): 976-986PENG Mengyao, GU Shuitao, ZHOU Yangjing, et al. Development and application of fatigue life evaluation software LtsFatigue based on LiToSim[J]. Applied Mathematics and Mechanics, 2022, 43(9): 976-986.(in Chinese) [19] 董彦民, 刘文珽, 杨超. 军用飞机结构耐久性设计的细节疲劳额定值方法[J]. 航空学报, 2010, 31(12): 2357-2364DONG Yanmin, LIU Wenting, YANG Chao. Military aircraft durability design method based on detail fatigue rating[J]. Acta Aeronautica et Astronautica Sinica, 2010, 31(12): 2357-2364.(in Chinese) -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号