Experimental Study on Dynamic Responses of Fuel Tanks Under Fragment Impacts

edited-by

edited-by

(Contributed by TANG Guangwu, M. AMM Editorial Board)-

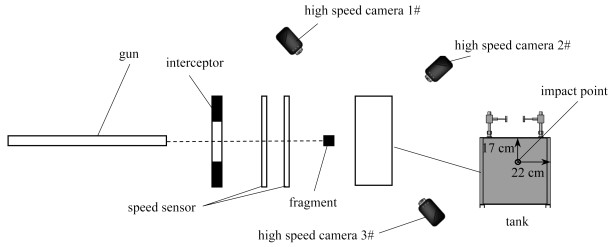

摘要: 研究了破片冲击作用下的油箱动力学响应行为. 通过开展弹道冲击实验,使用高速摄像机对实验过程进行记录,利用三维数字图像相关技术测试了后壁板的响应历史,分析了油箱在不同破片入射速度下的毁伤形式及动态响应行为. 结果表明:当破片以955~1 667 m/s的速度冲击油箱时,前壁板的损伤形式为圆形孔洞,后壁板损伤形式为花瓣形破口;随着破片入射速度的提升,后壁板的动态响应速度和应变水平都有了显著提升;后壁板的动态响应主要包括后壁板中心区域塑性变形和后壁板整体变形两个阶段;随着后壁板变形程度增大,在对角线和板边位置处产生了塑性铰线.Abstract: The dynamic responses of fuel tanks under fragment impacts were investigated. The ballistic impact tests on fuel tanks were carried out, the test processes were recorded with a high-speed camera, the dynamic morphologies of the fuel tank back wall were obtained with the 3D digital image correlation technique, and the damage forms and dynamic responses of the tanks under different fragment impact velocities were analyzed. The results show that, the damage to the tank front wall is in the form of circular holes and that to the back wall is in the form of "petal-shaped" breaches with radial cracks at fragment impact velocities of 955~1 667 m/s. The dynamic response speed and strain level of the tank back wall dramatically increases with the fragment impact velocity. The dynamic response of the tank back wall mainly includes 2 parts: the plastic deformation of the wall center and the overall deformation of the wall. With the increase of the deformation extent of the tank back wall, plastic hinge lines will occur along the wall diagonals and edges.

-

Key words:

- fragment impact /

- fuel tank /

- hydrodynamic ram /

- dynamic response /

- digital image correlation

edited-byedited-by1) (我刊编委唐光武来稿) -

表 1 实验工况

Table 1. The experimental working conditions

$\text { № . }$ fragment mass m/g fragment impact velocity v/(m·s-1) 1 6.7 955 2 6.8 1 195 3 6.8 1 364 4 6.7 1 667 -

[1] VARAS D, ZAERA R, LÓPEZ-PUENTE J. Numerical modelling of partially filled aircraft fuel tanks submitted to hydrodynamic ram[J]. Aerospace Science & Technology, 2012, 16 (1): 19-28. [2] NISHIDA M, TANAKA K. Experimental study of perforation and cracking of water-filled aluminum tubes impacted by steel spheres[J]. International Journal of Impact Engineering, 2006, 32 (12): 2000-2016. doi: 10.1016/j.ijimpeng.2005.06.010 [3] DELETOMBE E, FABIS J, DUPAS J, et al. Experimental analysis of 7.62 mm hydrodynamic ram in containers[J]. Journal of Fluids and Structures, 2013, 37 : 1-21. doi: 10.1016/j.jfluidstructs.2012.11.003 [4] 马丽英, 李向东, 周兰伟, 等. 高速破片撞击充不同介质液体容器的数值计算及实验研究[J]. 振动与冲击, 2018, 37 (24): 115-122. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201824019.htmMA Liying, LI Xiangdong, ZHOU Lanwei, et al. Numerical simulation and experimental study on high-speed fragment impact filling different liquid containers[J]. Journal of Vibration and Shock, 2018, 37 (24): 115-122. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201824019.htm [5] 张伟, 郭子涛, 肖新科, 等. 弹体高速入水特性实验研究[J]. 爆炸与冲击, 2011, 31 (6): 579-584. https://www.cnki.com.cn/Article/CJFDTOTAL-BZCJ201106005.htmZHANG Wei, GUO Zitao, XIAO Xinke, et al. Experimental investigations on behaviors of projectile high-speed water entry[J]. Explosion and Shock Waves, 2011, 31 (6): 579-584. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BZCJ201106005.htm [6] 张伟, 黄威, 任鹏, 等. 高速弹体水平入水产生冲击波特性[J]. 哈尔滨工业大学学报, 2016, 48 (4): 37-41. https://www.cnki.com.cn/Article/CJFDTOTAL-HEBX201604007.htmZHANG Wei, HUANG Wei, REN Peng, et al. The underwater shock wave characteristics caused by high speed horizontal water entry projectile[J]. Journal of Harbin Institute of Technology, 2016, 48 (4): 37-41. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HEBX201604007.htm [7] 解江, 李翰, 周书婷, 等. 爆炸冲击载荷下航空铝合金平板动态响应数值分析方法[J]. 应用数学和力学, 2017, 38 (4): 410-420. doi: 10.21656/1000-0887.370252XIE Jiang, LI Han, ZHOU Shuting, et al. A numerical method for dynamic responses of aviation aluminum alloy plates under blast loads[J]. Applied Mathematics and Mechanics, 2017, 38 (4): 410-420. (in Chinese) doi: 10.21656/1000-0887.370252 [8] 张宇, 王彬文, 刘小川, 等. 球形弹丸对不同构型充液油箱的毁伤效应[J]. 科学技术与工程, 2018, 18 (35): 26-32. https://www.cnki.com.cn/Article/CJFDTOTAL-KXJS201835004.htmZHANG Yu, WANG Binwen, LIU Xiaochuan, et al. Study on the damage effects of spherical projectiles on different configuration fuel tanks[J]. Science Technology and Engineering, 2018, 18 (35): 26-32. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-KXJS201835004.htm [9] KWON Y W, YANG K, ADAMS C. Modeling and simulation of high-velocity projectile impact on storage tank[J]. Journal of Pressure Vessel Technology, 2016, 138 (4): 041303. [10] KWON Y, YUN K. Numerical parametric study of hydrodynamic ram[J]. International Journal of Multiphysics, 2017, 11 (1): 15-47. [11] 杨砚世, 肖志华, 李向东. 破片撞击燃料箱时水锤效应的数值仿真研究[J]. 爆破器材, 2014, 43 (4): 26-31. https://www.cnki.com.cn/Article/CJFDTOTAL-BPQC201404006.htmYANG Yanshi, XIAO Zhihua, LI Xiangdong. Numerical simulation study on hydrodynamic ram due to the penetration of fuel tank by high energy fragments[J]. Explosive Materials, 2014, 43 (4): 26-31. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BPQC201404006.htm [12] 陈照峰, 刘国繁, 高伟, 等. 高速子弹穿透充液油箱的数值模拟[J]. 航空计算技术, 2014, 44 (1): 98-101. https://www.cnki.com.cn/Article/CJFDTOTAL-HKJJ201401025.htmCHEN Zhaofeng, LIU Guofan, GAO Wei, et al. Numerical simulation of filled fuel tank submitted high-speed bullet penetrated[J]. Aeronautical Computing Technique, 2014, 44 (1): 98-101. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKJJ201401025.htm [13] 李亚智, 陈钢. 充液箱体受弹丸撞击下动态响应的数值模拟[J]. 机械强度, 2007, 29 (1): 143-147. https://www.cnki.com.cn/Article/CJFDTOTAL-JXQD200701028.htmLI Yazhi, CHEN Gang. Numerical simulation of liquid-filled tank response to projectile impact[J]. Journal of Mechanical Strength, 2007, 29 (1): 143-147. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXQD200701028.htm [14] SUTTON M A, WOLTERS W J, PETERS W H, et al. Determination of displacements using an improved digital correlation method[J]. Image & Vision Computing, 1983, 1 (3): 133-139. [15] HELM J D, SUTTON M A, MCNEILL S R. Improved three-dimensional image correlation for surface displacement measurement[J]. Optical Engineering, 1996, 35 (7): 1911-1920. [16] TIWARI V, SUTTON M A, MCNEILL S R. Assessment of high-speed imaging systems for 2D and 3D deformation measurements: methodology development and validation[J]. Experimental Mechanics, 2007, 47 (4): 561-579. [17] 徐晓建, 邓子辰. 基于简化的应变梯度理论下Kirchhoff板模型边值问题的提法及其应用[J]. 应用数学和力学, 2022, 43 (4): 363-373. doi: 10.21656/1000-0887.420286XU Xiaojian, DENG Zichen. Boundary value problems of a kirchhoff type plate model based on the simplified strain gradient elasticity and the application[J]. Applied Mathematics and Mechanics, 2022, 43 (4): 363-373. (in Chinese) doi: 10.21656/1000-0887.420286 [18] 姚术健. 箱形结构内部爆炸等效缩比实验方法及破坏特性研究[D]. 博士学位论文. 长沙: 国防科学技术大学, 2016.YAO Shujian. Investigations on the scaling method and damage features of box-shaped structures under internal blast loading[D]. PhD Thesis. Changsha: National University of Defense Technology, 2016. (in Chinese) [19] 柳占立, 初东阳, 王涛, 等. 爆炸和冲击载荷下金属材料及结构的动态失效仿真[J]. 应用数学和力学, 2021, 42 (1): 1-14. doi: 10.21656/1000-0887.410262LIU Zhanli, CHU Dongyang, WANG Tao, et al. Dynamic failure simulation of metal materials and structures under blast and impact loading[J]. Applied Mathematics and Mechanics, 2021, 42 (1): 1-14. (in Chinese) doi: 10.21656/1000-0887.410262 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号