A Hierarchical Aggregation Modelling Method for Mobile Manipulators

-

摘要: 移动机械臂因机械臂在动态作业过程中的耦合效应会影响移动平台的运动特性,增加了整个系统的复杂度和非线性,给系统建模带来了极大挑战. 为此提出了一种新的层级聚合建模方法. 该方法依据分析力学中Udwadia-Kalaba(U-K)理论的层级属性,首先将移动机械臂划分为3个子系统,并分别利用Lagrange方程建立各自的无约束动力学模型,然后基于移动机械臂机械结构上的约束利用Udwadia-Kalaba基本方程(UKE)建立整体系统模型. 此外,针对系统存在初始条件偏差的情况,利用基于Lyapunov稳定性理论来补偿初始条件偏差,以达到收敛理想轨迹的目的. 仿真结果验证了该文所提出的建模方法的可行性.

-

关键词:

- Udwadia-Kalaba方法 /

- 层级聚合建模方法 /

- 移动机械臂 /

- 动力学建模

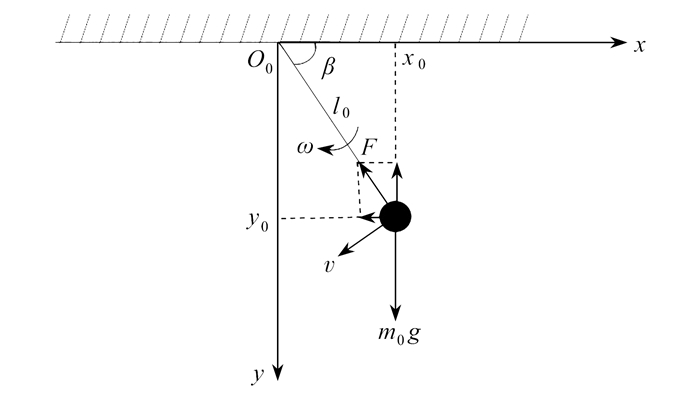

Abstract: The coupling effects of mobile manipulators on the motion characteristics of mobile platforms during the dynamic operation process, would increase the complexity and nonlinearity of the whole system and then bring great challenges to the system modelling. A new hierarchical aggregation modelling method was proposed to solve this issue. The method is based on the hierarchical properties of the Udwadia-Kalaba (UK) theory in the analytical mechanics. First, the mobile manipulator was divided into 3 subsystems, and the unconstrained dynamics of each one was modelled with the Lagrangian equations. Subsequently, the basic Udwadia-Kalaba equations (UKE) were employed to model the overall system, in view of the constraints within the mechanical structure of the mobile manipulator. In addition, the Lyapunov stability-based theory was used to compensate for the initial condition deviations to achieve convergence of the ideal trajectory. Simulation results validate the feasibility of the proposed modelling method. -

research institution robotic arm mass mr/kg platform mass mp/kg mass ratio δ University of Texas[2] 3.68 17.25 0.21 Ryerson University[3] 15.50 44.40 0.35 Hokkaido University[4] 4.40 20.56 0.21 Pukyong National University[5] 2.85 9.50 0.30 Iran University of Science and Technology[6] 0.72 6.00 0.12 Institute of Automation, CAS[7] 7.50 60.00 0.13 South China University of Technology[8] 2.00 10.00 0.20 表 2 机械臂几何参数

Table 2. Geometric parameters of the manipulator

joint number αi-1/(°) ai-1 di θi 1 0 0 0 θ1 2 90° 0 l1 θ2 3 0 l2 0 θ3 4 0 l3 0 0 表 3 系统动力学参数表

Table 3. System dynamics parameters

object mass m/kg length l/m moment of inertia I/(kg·m2) mobile platform 50 2 joint 1 2 0.5 0.625 joint 2 3 0.7 0.122 5 joint 3 2 0.5 0.042 end-effector 0.5 0.1 0.000 4 表 4 约束条件参数

Table 4. Constraint parameters

constraint initial condition $\begin{gathered}F_1: x(t)=\frac{\pi}{2} t; F_2: y(t)=\sin \left(\frac{\pi}{2} t\right); \\ F_3: \varphi(t)=\cos \left(\frac{\pi}{2} t\right); \\ F_4: x_{\mathrm{mp}}(t)=0.75+0.25 \cos (\pi t); \\ F_5: y_{\mathrm{mp}}(t)=\frac{0.25 \sqrt{2}}{2} \sin (\pi t); \\ F_6: z_{\mathrm{mp}}(t)=0.25-\frac{0.25 \sqrt{2}}{2} \sin (\pi t)\end{gathered}$ $\begin{gathered}x_0=1; y_0=1; \varphi_0=0; \\ \theta_1=-\frac{\pi}{2}; \theta_2=\frac{\pi}{2}; \theta_3=\frac{\pi}{6}; \\ \dot{x}_0=1; \dot{y}_0=1; \dot{\varphi}_0=0; \\ \dot{\theta}_1=-\frac{\pi}{2}; \dot{\theta}_2=\frac{\pi}{2}; \dot{\theta}_3=\frac{\pi}{6}\end{gathered}$ -

[1] 罗欣, 丁晓军. 地面移动作业机器人运动规划与控制研究综述[J]. 哈尔滨工业大学学报, 2021, 53(1): 1-15.LUO Xin, DING Xiaojun. Research and prospective on motion planning and control of ground mobile manipulators[J]. Journal of Harbin Institute of Technology, 2021, 53(1): 1-15. (in Chinese) [2] TANG C P, MILLER P T, KROVI V N, et al. Differential-flatness-based planning and control of a wheeled mobile manipulator: theory and experiment[J]. IEEE/ASME Transactions on Mechatronics, 2010, 16(4): 768-773. [3] LIU Y, LIU G. Interaction analysis and online tip-over avoidance for a reconfigurable tracked mobile modular manipulator negotiating slopes[J]. IEEE/ASME Transactions on Mechatronics, 2009, 15(4): 623-635. [4] ZHONG G, KOBAYASHI Y, HOSHINO Y, et al. System modeling and tracking control of mobile manipulator subjected to dynamic interaction and uncertainty[J]. Nonlinear Dynamics, 2013, 73(1): 167-182. [5] VIET T D, DOAN P T, HUNG N, et al. Tracking control of a three-wheeled omnidirectional mobile manipulator system with disturbance and friction[J]. Journal of Mechanical Science and Technology, 2012, 26(7): 2197-2211. doi: 10.1007/s12206-012-0541-1 [6] KORAYEM M H, ESFEDEN R A, NEKOO S R. Path planning algorithm in wheeled mobile manipulators based on motion of arms[J]. Journal of Mechanical Science and Technology, 2015, 29(4): 1753-1763. doi: 10.1007/s12206-015-0349-x [7] TAN X W, ZHAO D B, YI J. Motion control of omnidirectional mobile manipulators, part Ⅰ: modeling and control[J]. Journal of Mechanical Engineering, 2009, 45(1): 35-41. doi: 10.3901/JME.2009.01.035 [8] LI Z, YANG C, TANG Y. Decentralised adaptive fuzzy control of coordinated multiple mobile manipulators interacting with non-rigid environments[J]. IET Control Theory & Applications, 2013, 7(3): 397-410. [9] LIU K, LEWIS F L. Decentralized continuous robust controller for mobile robots[C]//Proceedings, IEEE International Conference on Robotics and Automation. Cincinnati, OH, USA, 1990: 1822-1827. [10] 杨贺贺, 陈炜, 童嘉琦, 等. 含柔性关节的轮式移动机械臂的动力学分析[J]. 天津理工大学学报, 2022, 38(2): 45-51.YANG Hehe, CHEN Wei, TONG Jiaqi, et al. Dynamic analysis of wheeled mobile manipulator with flexible joints[J]. Journal of Tianjin University of Technology, 2022, 38(2): 45-51. (in Chinese) [11] 陈良港, 张方, 张建光, 等. 基于对偶四元数移动机械臂运动学建模与控制[J]. 科技创新与应用, 2022, 12(5): 1-5.CHEN Lianggang, ZHANG Fang, ZHANG Jianguang, et al. Dynamic analysis of wheeled mobile manipulator with flexible joints[J]. Technology Innovation and Application, 2022, 12(5): 1-5. (in Chinese) [12] 魏丽君, 吴海波, 刘海龙, 等. 基于D-H算法的移动机械臂正运动学研究[J]. 计量与测试技术, 2020, 47(10): 1-5.WEI Lijun, WU Haibo, LIU Hailong, et al. Research on trajectory planning of mobile manipulator based on improved gradient projection algorithm[J]. Metrology & Measurement Technique, 2020, 47(10): 1-5. (in Chinese) [13] ZHONG G, KOBAYASHI Y, HOSHINO Y, et al. System modeling and tracking control of mobile manipulator subjected to dynamic interaction and uncertainty[J]. Nonlinear Dynamics, 2013, 73(1): 167-182. [14] UDWADIA F E, KALABA R E. Analytical Dynamics: a New Approach[M]. New York: Cambridge University Press, 1996. [15] UDWADIA F E, KALABA R E. A new perspective on constrained motion[J]. Proceedings of the Royal Society of London (Series A): Mathematical and Physical Sciences, 1992, 439(1906): 407-410. doi: 10.1098/rspa.1992.0158 [16] UDWADIA F E, KALABA R E. Explicit equations of motion for mechanical systems with nonideal constraints[J]. Journal of Applied Mechanics, 2001, 68(3): 462-467. doi: 10.1115/1.1364492 [17] HUANG J, CHEN Y H, GUO K. Novel approach to multibody system modeling: cascading and clustering[J]. Journal of Aerospace Engineering, 2014, 27(2): 279-290. doi: 10.1061/(ASCE)AS.1943-5525.0000217 [18] 董方方, 喻斌, 赵晓敏, 等. 双移动机械臂空间协作动力学建模研究[J]. 应用数学和力学, 2022, 43(8): 846-856. doi: 10.21656/1000-0887.420223DONG Fangfang, YU Bin, ZHAO Xiaomin, et al. Dynamic modeling of spatial cooperation between dual-arm mobile manipulators[J]. Applied Mathematics and Mechanics, 2022, 43(8): 846-856. (in Chinese) doi: 10.21656/1000-0887.420223 [19] 韩江, 汪鹏, 董方方, 等. 基于Udwadia-Kalaba方法的平面冗余并联机器人建模与轨迹跟踪控制[J]. 应用数学和力学, 2020, 41(11): 1183-1196. doi: 10.21656/1000-0887.400363HAN Jiang, WANG Peng, DONG Fangfang, et al. Modeling and control of planar redundant parallel robots based on the Udwadia-Kalaba method[J]. Applied Mathematics and Mechanics, 2020, 41(11): 1183-1196. (in Chinese) doi: 10.21656/1000-0887.400363 [20] UDWADIA F E. A new perspective on the tracking control of nonlinear structural and mechanical systems[J]. Proceedings of the Royal Society of London (Series A): Mathematical, Physical and Engineering Sciences, 2003, 459(2035): 1783-1800. doi: 10.1098/rspa.2002.1062 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号