The Perturbation Neural Network Surrogate Model Method for Size-Topology Synthetical Optimization of Wing Rib Trailing Edges With Flap Tracks

-

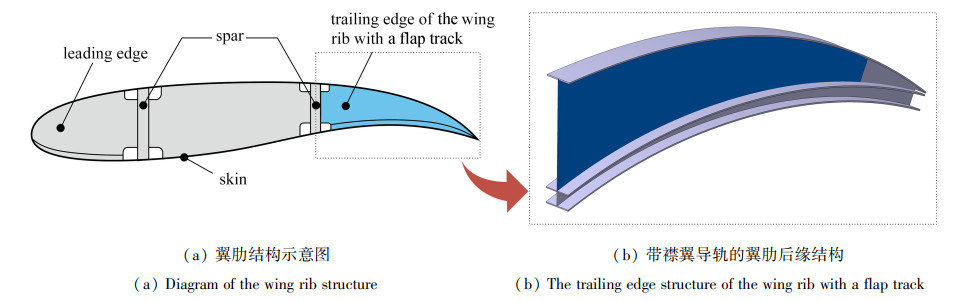

摘要: 带襟翼导轨的翼肋后缘设计需要确定肋缘条、腹板的尺寸和肋腹板的拓扑形状,对此提出了一种针对尺寸-拓扑综合优化的摄动神经网络(perturbation neural network, PNN)代理模型法. 其基本思想是基于拓扑优化对参数的敏感性,引入了对试验设计(design of experiments, DOE)样本点的摄动,通过过滤手段捕获拓扑突变点,并降低数值噪声,极大地提高了代理模型的预测精度,将拓扑优化过程作为黑盒,直接建立起尺寸变量与拓扑优化后结构响应的代理模型. 最后在代理模型上进行优化,得到了结构尺寸与拓扑形状的最优组合. 该文完成了一个翼肋后缘优化典型算例,证明了该方法的有效性和优越性.Abstract: The design of wing rib trailing edges with flap tracks requires the determination of sizes of the rib edge strips, the webs and the topological shapes of the rib webs. Therefore, a perturbation neural network surrogate model method was proposed for the size-topology synthetical optimization. The basic idea is that, based on the sensitivity of topology optimization to parameters, the perturbation is introduced in the DOE samples to capture the topological mutation points by means of the filtering measure, and reduce the numerical noise, which greatly improves the prediction accuracy of the surrogate model. With the topology optimization process viewed as a black box, the surrogate model for the size variables and topology optimized structural responses was directly built up. Finally, optimization was carried out on the surrogate model to obtain the optimal combination of structural sizes and topological shapes. A typical calculation example of wing rib trailing edge optimization demonstrates the validity and superiority of the proposed method.

-

Key words:

- perturbation neural network /

- size optimization /

- topology optimization /

- surrogate model /

- wing rib

-

surrogate model prediction accuracy characteristic PRS low high efficiency Kriging high sensitivity to digital noise RBF medium the best effect in general 表 2 变量说明及取值范围

Table 2. Variable description and range

variable name symbol range upper edge strip thickness t1/mm 3.0~8.0 middle edge strip thickness t2/mm 3.0~8.0 lower edge strip thickness t3/mm 3.0~8.0 lower web thickness t4/mm 3.0~8.0 upper web thickness t5/mm 1.0~4.0 表 3 传统优化中变量与响应各阶段结果

Table 3. Variable and response results at each stage in traditional optimization

variable or response initial value 1st size optimization final result t1/mm 3.00 3.26 3.00 t2/mm 3.00 3.00 3.00 t3/mm 3.00 3.00 3.00 t4/mm 3.00 3.70 4.54 t5/mm 1.00 1.49 1.56 δmax/mm 10.72 9.57 10.90 σmax/MPa 394.60 299.99 299.94 w/kg 1.842 2.12 2.06 表 4 基于PNN的优化结果

Table 4. Optimization results based on PNN

variable or response t1/mm t2/mm t3/mm t4/mm t5/mm δ/mm σ/MPa w/kg result 3.00 3.00 3.00 3.71 1.72 7.44 300.15 1.90 表 5 代理模型精度对比

Table 5. Surrogate model accuracy comparison

criterion Kriging with PNN PRS with PNN RBF with PNN Kriging without PNN R2 0.915 0.536 0.897 0.782 RRMSE 0.105 0.254 0.112 0.197 -

[1] 张广圣, 王其祚. 机械结构多级优化的问题与对策[J]. 合肥工业大学学报(自然科学版), 1990, 13(1): 52-58.ZHANG Guangsheng, WANG Qizuo. Multilevel mechanical structure optimization difficulties and strategis[J]. Journal of Hefei University of Technology (Natural Science), 1990, 13(1): 52-58. (in Chinese) [2] 谢浩然, 贺媛媛, 陶志坚. 扑旋翼飞行器气动特性分析及机翼拓扑优化设计[J]. 南京航空航天大学学报, 2020, 52(2): 280-287.XIE Haoran, HE Yuanyuan, TAO Zhijian. Aerodynamic characteristics analysis and topology optimization design of wing of flapping rotorcraft[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2020, 52(2): 280-287. (in Chinese) [3] KUTYŁOWSKI R, SZWECHŁOWICZ M. Application of topology optimization to thighbone and thighbone/implant structure modelling[J]. Archives of Civil and Mechanical Engineering, 2019, 19(4): 1006-1019. doi: 10.1016/j.acme.2019.05.007 [4] BRIOT S, GOLDSZTEJN A. Topology optimization of industrial robots: application to a five-bar mechanism[J]. Mechanism and Machine Theory, 2018, 120: 30-56. doi: 10.1016/j.mechmachtheory.2017.09.011 [5] GAO X, MA H. Topology optimization of continuum structures under buckling constraints[J]. Computers & Structures, 2015, 157: 142-152. [6] 张东东, 栾福强, 赵礼辉, 等. 基于变体积约束的阻尼材料微结构拓扑优化研究[J]. 应用数学和力学, 2022, 43(6): 648-659. doi: 10.21656/1000-0887.420206ZHANG Dongdong, LUAN Fuqiang, ZHAO Lihui, et al. Research on topology optimization of damping material microstructures with varied volume constraints[J]. Applied Mathematics and Mechanics, 2022, 43(6): 648-659. (in Chinese) doi: 10.21656/1000-0887.420206 [7] LÓPEZ J, ANITESCU C, RABCZUK T. Isogeometric structural shape optimization using automatic sensitivity analysis[J]. Applied Mathematical Modelling, 2021, 89(2): 1004-1024. [8] GHOMMEM M, COLLIER N, NIEMI A H, et al. On the shape optimization of flapping wings and their performance analysis[J]. Aerospace Science and Technology, 2014, 32(1): 274-292. doi: 10.1016/j.ast.2013.10.010 [9] 刘宏亮, 祝雪峰, 杨迪雄. 基于等几何分析的结构优化设计研究进展[J]. 固体力学学报, 2018, 39(3): 248-267.LIU Hongliang, ZHU Xuefeng, YANG Dixiong. Research advances in isogeometric analysis-based optimum design of structure[J]. Chinese Journal of Solid Mechanics, 2018, 39(3): 248-267. (in Chinese) [10] 荣见华, 姜节胜, 胡德文, 等. 基于应力及其灵敏度的结构拓扑渐进优化方法[J]. 力学学报, 2003, 35(5): 584-591. doi: 10.3321/j.issn:0459-1879.2003.05.010RONG Jianhua, JIANG Jiesheng, HU Dewen, et al. A structural topology evolutionary optimization method based on stresses and their sensitivity[J]. Chinese Journal of Theoretical and Applied Mechanics, 2003, 35(5): 584-591. (in Chinese) doi: 10.3321/j.issn:0459-1879.2003.05.010 [11] BENNACEUR M, XU Y, LAYACHI H. Wing rib stress analysis and design optimization using constrained natural element method[J]. IOP Conference Series: Materials Science and Engineering, 2017, 234(3): 12-18. [12] AZID I A, KWAN A S K, SEETHARAMU K N. An evolutionary approach for layout optimization of a three-dimensional truss[J]. Structural and Multidisciplinary Optimization, 2002, 24(4): 333-337. doi: 10.1007/s00158-002-0244-9 [13] RAJAN S D. Sizing, shape, and topology design optimization of trusses using genetic algorithm[J]. Journal of Structural Engineering, 1995, 121(10): 1480-1487. doi: 10.1061/(ASCE)0733-9445(1995)121:10(1480) [14] DUAN B Y, YE S H. A mixed method for shape optimization of skeletal structures[J]. Engineering Optimization, 1986, 10(3): 183-197. doi: 10.1080/03052158608902536 [15] 隋允康, 高峰, 龙连春, 等. 基于层次分解方法的桁架结构形状优化[J]. 计算力学学报, 2006, 23(1): 46-51.SUI Yunkang, GAO Feng, LONG Lianchun, et al. Shape optimization of truss structure based on hierarchical decomposition method[J]. Chinese Journal of Computational Mechanics, 2006, 23(1): 46-51. (in Chinese) [16] FLAGER F, ADYA A, HAYMAKER J, et al. A bi-level hierarchical method for shape and member sizing optimization of steel truss structures[J]. Computers & Structures, 2014, 131: 1-11. [17] 石连栓, 王跃方, 孙焕纯. 具有动应力、位移和稳定性约束的离散变量桁架结构布局优化设计算法[J]. 应用数学和力学, 2006, 27(5): 527-532. doi: 10.3321/j.issn:1000-0887.2006.05.004SHI Lianshuan, WANG Yuefang, SUN Huanchun. Approach for layout optimization of truss structures with discrete variables under dynamic stress, displacement and stability constraints[J]. Applied Mathematics and Mechanics, 2006, 27(5): 527-532. (in Chinese) doi: 10.3321/j.issn:1000-0887.2006.05.004 [18] 高普阳, 赵子桐, 杨扬. 基于卷积神经网络模型数值求解双曲型偏微分方程的研究[J]. 应用数学和力学, 2021, 42(9): 932-947. doi: 10.21656/1000-0887.420050GAO Puyang, ZHAO Zitong, YANG Yang. Study on numerical solutions to hyperbolic partial differential equations based on the convolutional neural network model[J]. Applied Mathematics and Mechanics, 2021, 42(9): 932-947. (in Chinese) doi: 10.21656/1000-0887.420050 [19] 吴雨程, 殷红, 彭珍瑞. 基于Kriging模型和提升小波变换的随机模型修正[J]. 应用数学和力学, 2022, 43(7): 761. doi: 10.21656/1000-0887.420128WU Yucheng, YIN Hong, PENG Zhenrui. Stochastic model updating based on Kriging model and lifting wavelet transform[J]. Applied Mathematics and Mechanics, 2022, 43(7): 761. (in Chinese) doi: 10.21656/1000-0887.420128 [20] 陶然, 周焕林, 孟增, 等. 基于响应面法和改进算术优化算法的抱杆优化设计[J]. 应用数学和力学, 2022, 43(10): 1113. doi: 10.21656/1000-0887.420318TAO Ran, ZHOU Huanlin, MENG Zeng, et al. Optimization design of holding poles based on the response surface methodology and the improved arithmetic optimization algorithm[J]. Applied Mathematics and Mechanics, 2022, 43(10): 1113. (in Chinese) doi: 10.21656/1000-0887.420318 [21] 穆雪峰, 姚卫星, 余雄庆, 等. 多学科设计优化中常用代理模型的研究[J]. 计算力学学报, 2005, 22(5): 608-612.MU Xuefeng, YAO Weixing, YU Xiongqing, et al. A survey of surrogate models used in mdo[J]. Chinese Journal of Computational Mechanics, 2005, 22(5): 608-612. (in Chinese) -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号