Application of Enthalpy Deficit Flamelet Model in Spray Combustion Simulation

-

摘要: 基于OpenFOAM的求解器,使用大涡模拟结合纯气相火焰面生成流形方法进行了喷雾燃烧模拟,并采用简单的扣焓处理来考虑蒸发热损失.该求解器首先借助悉尼乙醇喷雾火焰标模EtF7进行了验证.预测的气相平均温度和液滴统计数据与实验数据吻合良好,精度与喷雾火焰面模型接近.湍流-化学反应相互作用建模处理可能对模拟精度有更大影响.然后,对一个真实的航空发动机折流燃烧室进行了两组工况的数值模拟.仿真结果合理展现了两种工况下喷雾火焰燃烧的不同特征,并且预测的总压损失值接近于测量值.

-

关键词:

- 喷雾燃烧 /

- 大涡模拟 /

- 火焰面生成流形 /

- 航空发动机折流燃烧室

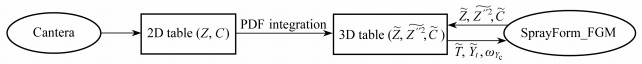

Abstract: An OpenFOAM-based solver for spray combustion simulation with the large eddy simulation (LES) and the flamelet generated manifold (FGM) method, was developed. A simple reduction of the temperature was employed to account for the evaporative heat loss. The solver was firstly validated against the Sydney piloted ethanol spray flame benchmark EtF7. The predicted mean gas temperature and droplet statistics correspond well with the experimental data and have similar accuracy to the spray flamelet model. The turbulence-chemistry interaction modeling may have a larger influence on the simulation accuracy. Then a realistic gas turbine slinger combustor was simulated with 2 sets of operating conditions. The simulation results reveal different flame characteristics of the 2 working conditions. The predicted total pressure losses are close to the measured values.-

Key words:

- spray combustion /

- large eddy simulation /

- flamelet generated manifold /

- gas turbine slinger combustor

edited-byedited-by1) (我刊编委王利坡来稿) -

表 1 液相引起的源项表达式

Table 1. Expressions of liquid source terms

source term expression Sρ $ -\frac{1}{V_c} \sum\limits_p \dot{m}_p N_p$ Su, i $ \frac{1}{V_c} \sum_p m_p N_p\left[\left(U_{p, i}^{t_n+\Delta t}-U_{p, i}^{t_n}\right) / \Delta t-g_i\right]-\frac{1}{V_c} \sum\limits_p \dot{m}_p N_p U_{p, i}^{t_n}$ 表 2 两组不同工况的测量数据

Table 2. Measured data in 2 working conditions

index working condition 1 working condition 2 air inlet mass flow rate ṁair/(kg·s-1) 2.313 2.707 fuel inlet mass flow rate ṁfuel/(g·s-1) 13.8 31.7 fuel air mass ratio (F/A)/% 0.596 6 1.171 7 air inlet temperature Tair/K 300 300 fuel inlet temperature Tfuel/K 300 300 air inlet total pressure Pt, air/kPa 305.103 408.172 total pressure loss ΔPt/kPa 50.912 74.861 表 3 进程变量源项在不同燃烧区域的条件均值

Table 3. Conditional means of progress variable source terms in different combustion zones

working condition ωY/(kg·m-3·s-1) ξ=-1 ξ=+1 working condition 1 5.03 4.44 working condition 2 13.82 7.03 -

[1] GOUNDER J D, KOURMATZIS A, MASRI A R. Turbulent piloted dilute spray flames: flow fields and droplet dynamics[J]. Combustion and Flame, 2012, 159(11): 3372-3397. doi: 10.1016/j.combustflame.2012.07.014 [2] YAN Y, ZHAO J, ZHANG J, et al. Large-eddy simulation of two-phase spray combustion for gas turbine combustors[J]. Applied Thermal Engineering, 2008, 28(11/12): 1365-1374. [3] JONES W, MARQUIS A, VOGIATZAKI K. Large-eddy simulation of spray combustion in a gas turbine combustor[J]. Combustion and Flame, 2014, 161(1): 222-239. doi: 10.1016/j.combustflame.2013.07.016 [4] PETERS N. Laminar diffusion flamelet models in non-premixed turbulent combustion[J]. Progress in Energy and Combustion Science, 1984, 10(3): 319-339. doi: 10.1016/0360-1285(84)90114-X [5] PIERCE C D, MOIN P. Progress-variable approach for large-eddy simulation of non-premixed turbulent combustion[J]. Journal of Fluid Mechanics, 2004, 504: 73-97. doi: 10.1017/S0022112004008213 [6] VREMAN A W, ALBRECHT B A, VAN OIJEN J A, et al. Premixed and nonpremixed generated manifolds in large-eddy simulation of Sandia flame D and F[J]. Combustion and Flame, 2008, 153(3): 394-416. doi: 10.1016/j.combustflame.2008.01.009 [7] NGUYEN P D, VERVISCH L, SUBRAMANIAN V, et al. Multidimensional flamelet-generated manifolds for partially premixed combustion[J]. Combustion and Flame, 2010, 157(1): 43-61. doi: 10.1016/j.combustflame.2009.07.008 [8] CHEN J, LIU M, CHEN Y. Optimizing progress variable definition in flamelet-based dimension reduction in combustion[J]. Applied Mathematics and Mechanics (English Edition), 2015, 36(11): 1481-1498. doi: 10.1007/s10483-015-1997-7 [9] LI T, KONG F, XU B, et al. Turbulent combustion modeling using a flamelet generated manifold approach: a validation study in openfoam[J]. Applied Mathematics and Mechanics (English Edition), 2019, 40(8): 1197-1210. doi: 10.1007/s10483-019-2503-6 [10] MOIN P, APTE S V. Large-eddy simulation of realistic gas turbine combustors[J]. AIAA Journal, 2006, 44(4): 698-708. doi: 10.2514/1.14606 [11] BABA Y, KUROSE R. Analysis and flamelet modelling for spray combustion[J]. Journal of Fluid Mechanics, 2008, 612: 45-79. doi: 10.1017/S0022112008002620 [12] MA L, ROEKAERTS D. Modeling of spray jet flame under mild condition with non-adiabatic FGM and a new conditional droplet injection model[J]. Combustion and Flame, 2016, 165: 402-423. doi: 10.1016/j.combustflame.2015.12.025 [13] KONG F, LI T, CHENG C, et al. Modeling of spray flame in gas turbine combustors with LES and FGM[J]. Fuel, 2022, 325: 124756. doi: 10.1016/j.fuel.2022.124756 [14] GUTHEIL E, SIRIGNANO W A. Counterflow spray combustion modeling with detailed transport and detailed chemistry[J]. Combustion and Flame, 1998, 113(1/2): 92-105. [15] YI R, ZHANG X, CHEN C. Large eddy simulation of a turbulent dilute ethanol flame using the two-phase spray flamelet generated manifold approach[J]. Combustion Science and Technology, 2022. DOI: 10.1080/00102202.2022.2139612. [16] HU Y, KAI R, KUROSE R, et al. Large eddy simulation of a partially pre-vaporized ethanol reacting spray using the multiphase DTF/flamelet model[J]. International Journal of Multiphase Flow, 2020, 125: 103216. doi: 10.1016/j.ijmultiphaseflow.2020.103216 [17] FRANZELLI B, VIÉ A, IHME M. On the generalisation of the mixture fraction to a monotonic mixing-describing variable for the flamelet formulation of spray flames[J]. Combustion Theory and Modelling, 2015, 19(6): 773-806. doi: 10.1080/13647830.2015.1099740 [18] WANG Y, CAI R, SHAO C, et al. A priori and a posteriori studies of a novel spray flamelet tabulation methodology considering evaporation effects[J]. Fuel, 2023, 331(2): 125892. [19] GERMANO M, PIOMELLI U, MOIN P, et al. A dynamic subgrid-scale eddy viscosity model[J]. Physics of Fluids A: Fluid Dynamics, 1991, 3(7): 1760-1765. doi: 10.1063/1.857955 [20] BILGER R, STARNER S, KEE R. On reduced mechanisms for methane air combustion in nonpremixed flames[J]. Combustion and Flame, 1990, 80(2): 135-149. doi: 10.1016/0010-2180(90)90122-8 [21] CHRIGUI M, GOUNDER J, SADIKI A, et al. Partially premixed reacting acetone spray using les and fgm tabulated chemistry[J]. Combustion and Flame, 2012, 159(8): 2718-2741. doi: 10.1016/j.combustflame.2012.03.009 [22] RANZ W, MARSHALL W. Evaporation from droplets[J]. Chemical Engineering Progress, 1952, 48(3): 141-146. [23] WEHRFRITZ A, KAARIO O, VUORINEN V, et al. Large eddy simulation of n-dodecane spray flames using flamelet generated manifolds[J]. Combustion and Flame, 2016, 167: 113-131. doi: 10.1016/j.combustflame.2016.02.019 [24] KORNEV N, KRÖGER H, TURNOW J, et al. Synthesis of artificial turbulent fields with prescribed second-order statistics using the random-spot method[J]. PAMM: Proceedings in Applied Mathematics and Mechanics, 2007, 7(1): 2100047-2100048. doi: 10.1002/pamm.200700460 [25] YAO T, PEI Y, ZHONG B J, et al. A compact skeletal mechanism for n-dodecane with optimized semi-global low-temperature chemistry for diesel engine simulations[J]. Fuel, 2017, 191: 339-349. doi: 10.1016/j.fuel.2016.11.083 [26] 曾川, 王洪铭, 单鹏. 微涡喷发动机离心甩油盘环形折流燃烧室的设计与实验研究[J]. 航空动力学报, 2003, 18(1): 92-96. https://www.cnki.com.cn/Article/CJFDTOTAL-HKDI200301016.htmZENG Chuan, WANG Hongming, SHAN Peng. The design and study of the annular combustion chamber with centrifugal fuel injection[J]. Journal of Aerospace Power, 2003, 18(1): 92-96. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKDI200301016.htm -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号