Symplectic Superposition-Based Analytical Solutions for Buckling of Non-Lévy-Type Orthotropic Cylindrical Shells

-

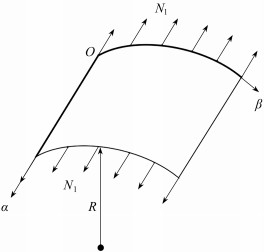

摘要: 该文基于笔者提出的辛叠加方法得到了经典解法难以直接获得的典型非Lévy型正交各向异性开口圆柱壳屈曲问题的解析解. 首先,基于Donnell薄壳理论建立了正交各向异性开口圆柱壳屈曲问题的Hamilton体系控制方程,然后将非Lévy型边界下的原问题拆分为两个子问题,在Hamilton体系下利用分离变量和辛本征展开等数学手段对子问题进行求解,最后基于原问题边界条件,通过子问题解的叠加求得原问题的解析解. 数值算例表明,辛叠加解析解与有限元数值解结果吻合良好. 同时,定量研究了长度和厚度等参数对屈曲载荷的影响. 相比于半逆解法等传统解析方法,辛叠加方法基于严格的数学推导,无需假定解的形式,可以获得更多类似问题的解析解.Abstract: Based on the symplectic superposition method (SSM) pioneered by the authors, the buckling problem of typical non-Lévy-type orthotropic cylindrical shells was solved analytically, which is difficult to handle with conventional analytical methods. The Hamiltonian system-based governing equations for buckling of orthotropic cylindrical shells were firstly established based on Donnell's shell theory. The original problem under non-Lévy-type boundary conditions was then divided into 2 subproblems, and each subproblem was solved with the mathematical techniques incorporating separation of variables and symplectic eigen expansion within the Hamiltonian framework. The analytical solution of the original problem was finally given through the superposition of the sub-solutions to satisfy the boundary conditions of the original problem. The numerical examples under consideration show that, the SSM-based analytical solutions are in good agreement with the finite element results. In addition, the effects of parameters including the length and the thickness on the critical buckling loads were quantitatively studied. Compared with the conventional analytical methods such as the semi-inverse method, the SSM works based on rigorous mathematical derivation without any assumption of the solution forms, and can obtain reliable analytical solutions to more similar issues.

-

Key words:

- orthotropic /

- cylindrical shell /

- buckling /

- symplectic superposition method /

- analytical solution

edited-byedited-by1) (我刊编委李锐来稿) -

表 1 a=b=R=1 m时,开口圆柱壳前十阶屈曲载荷的收敛性研究(单位:kN/m)

Table 1. Convergence of the 1st 10 buckling loads on the cylindrical shell with a=b=R=1 m (unit: kN/m)

δ/m number of series terms mode 1 2 3 4 5 6 7 8 9 10 1 10 1 220.2 1 392.5 1 501.8 1 531.1 1 830.1 1 887.1 1 986.8 2 049.8 2 201.7 2 286.1 20 1 220.2 1 392.5 1 501.8 1 531.1 1 830.1 1 887.1 1 986.7 2 049.8 2 201.7 2 286.0 30 1 220.2 1 392.5 1 501.8 1 531.1 1 830.1 1 887.1 1 986.7 2 049.8 2 201.7 2 286.0 0.05 10 285.61 300.36 307.11 322.16 367.86 374.32 383.09 385.92 406.60 430.85 20 285.61 300.35 307.08 322.16 367.86 374.30 383.07 385.91 406.58 430.84 30 285.61 300.35 307.08 322.16 367.86 374.30 383.07 385.91 406.58 430.84 表 2 b=1 m,δ=0.01 m时,开口圆柱壳的前十阶屈曲载荷(单位:kN/m)

Table 2. The 1st 10 buckling loads on the cylindrical shell with b=1 m and δ=0.01 m (unit: kN/m)

a/m R/m method mode 1 2 3 4 5 6 7 8 9 10 1 1 FEM 1 218.3 1 366.8 1 473.7 1 510.5 1 789.6 1 869.8 1 988.4 1 990.6 2 129.8 2 209.1 present 1 220.2 1 392.5 1 501.8 1 531.1 1 830.1 1 887.1 1 986.7 2 049.8 2 201.7 2 286.0 2 FEM 757.89 831.37 1 091.2 1 117.9 1 165.4 1 240.7 1 646.8 1 792.0 1 826.1 1 852.6 present 765.18 835.57 1 114.0 1 138.6 1 182.1 1 268.5 1 685.3 1 862.5 1 899.7 1 911.4 10 FEM 460.16 607.93 876.33 955.33 1 093.4 1 164.2 1 601.8 1 649.9 1 729.0 1 809.0 present 465.05 614.49 897.36 978.51 1 108.2 1 191.8 1 639.5 1 720.4 1 802.8 1 867.2 2 1 FEM 1 074.7 1 089.4 1 140.3 1 169.6 1 249.8 1 363.0 1 377.4 1 472.8 1 569.4 1 580.9 present 1 091.5 1 093.6 1 154.4 1 185.4 1 259.3 1 373.8 1 401.7 1 500.8 1 596.8 1 609.9 2 FEM 580.60 630.27 667.79 766.72 838.42 842.57 902.04 903.58 935.23 965.62 present 584.52 635.65 668.25 767.03 843.13 850.34 913.12 914.70 947.30 975.79 10 FEM 172.86 262.98 413.54 460.57 468.95 663.31 721.07 752.43 815.28 852.77 present 173.45 264.58 416.49 465.46 473.21 674.36 727.81 765.29 824.88 863.90 表 3 b=1 m,δ=0.005 m时,开口圆柱壳的前十阶屈曲载荷(单位:kN/m)

Table 3. The 1st 10 buckling loads on the cylindrical shell with b=1 m and δ=0.005 m (unit: kN/m)

a/m R/m method mode 1 2 3 4 5 6 7 8 9 10 1 1 FEM 284.75 299.42 306.74 320.64 366.45 372.05 382.91 384.16 407.24 429.56 present 285.61 300.35 307.08 322.16 367.86 374.30 383.07 385.91 406.58 430.84 2 FEM 154.95 174.48 188.02 192.21 228.72 237.54 252.14 255.64 274.23 284.70 present 154.94 175.10 188.71 192.72 229.59 238.04 251.97 257.08 276.15 286.74 10 FEM 63.880 79.045 115.44 123.84 139.42 149.47 204.84 215.42 224.94 232.71 present 64.008 79.224 116.00 124.47 139.74 150.21 205.71 217.29 226.92 234.12 2 1 FEM 267.91 270.50 272.42 274.90 291.75 300.12 306.17 309.58 313.35 334.04 present 268.73 270.68 273.02 275.64 292.06 301.30 306.66 311.87 314.53 335.13 2 FEM 138.49 138.74 144.98 148.91 159.28 172.95 175.71 187.93 199.89 201.64 present 138.79 138.92 145.27 149.24 159.52 173.18 176.28 188.62 200.38 202.34 10 FEM 29.704 41.073 54.651 61.639 63.996 88.736 92.837 97.687 104.21 109.03 present 29.727 41.116 54.736 61.757 64.127 89.029 93.008 98.038 104.43 109.30 -

[1] 熊健, 李志彬, 刘惠彬, 等. 航空航天轻质复合材料壳体结构研究进展[J]. 复合材料, 2021, 38(6): 1629-1650.XIONG Jian, LI Zhibin, LIU Huibin, et al. Advances in aerospace lightweight composite shell structure[J]. Acta Materiae Compositae Sinica, 2021, 38(6): 1629-1650. (in Chinese) [2] WEI K, PENG Y, QU Z, et al. Lightweight composite lattice cylindrical shells with novel character of tailorable thermal expansion[J]. International Journal of Mechanical Sciences, 2018, 137: 77-85. doi: 10.1016/j.ijmecsci.2018.01.017 [3] 王晓旭, 张典堂, 钱坤, 等. 深海纤维增强树脂复合材料圆柱耐压壳力学性能的研究进展[J]. 复合材料学报, 2020, 37(1): 16-26.WANG Xiaoxu, ZHANG Diantang, QIAN Kun, et al. Research progress on mechanical properties of deep-sea fiber reinforced resin composite cylindrical pressure shells[J]. Acta Materiae Compositae Sinica, 2020, 37(1): 16-26. (in Chinese) [4] TENG J G, YU T, FERNANDO D. Strengthening of steel structures with fiber-reinforced polymer composites[J]. Journal of Constructional Steel Research, 2012, 78: 131-143. doi: 10.1016/j.jcsr.2012.06.011 [5] MOROZOV E V, LOPATIN A V, NESTEROV V A. Finite-element modelling and buckling analysis of anisogrid composite lattice cylindrical shells[J]. Composite Structures, 2011, 93(2): 308-323. doi: 10.1016/j.compstruct.2010.09.014 [6] RAVARI M R K, TALEBI S, SHAHIDI A R. Analysis of the buckling of rectangular nanoplates by use of finite-difference method[J]. Meccanica, 2014, 49(6): 1443-1455. doi: 10.1007/s11012-014-9917-x [7] LOPATIN A V, MOROZOV E V. Buckling of the composite sandwich cylindrical shell with clamped ends under uniform external pressure[J]. Composite Structures, 2015, 122: 209-216. doi: 10.1016/j.compstruct.2014.11.048 [8] LOPATIN A V, MOROZOV E V. Buckling of composite cylindrical shells with rigid end disks under hydrostatic pressure[J]. Composite Structures, 2017, 173: 136-143. doi: 10.1016/j.compstruct.2017.03.109 [9] 张磊, 张文明, 王林, 等. 基于小波Galerkin法的矩形薄板二次屈曲分析[J]. 应用数学和力学, 2023, 44(1): 25-35. doi: 10.21656/1000-0887.430097ZHANG Lei, ZHANG Wenming, WANG Lin, et al. Secondary buckling analysis of thin rectangular plates based on the wavelet Galerkin method[J]. Applied Mathematics and Mechanics, 2023, 44(1): 25-35. (in Chinese) doi: 10.21656/1000-0887.430097 [10] GHAHFAROKHI D S, RAHIMI G. An analytical approach for global buckling of composite sandwich cylindrical shells with lattice cores[J]. International Journal of Solids and Structures, 2018, 146: 69-79. doi: 10.1016/j.ijsolstr.2018.03.021 [11] SAFARPOUR H, GHANBARI B, GHADIRI M. Buckling and free vibration analysis of high speed rotating carbon nanotube reinforced cylindrical piezoelectric shell[J]. Applied Mathematical Modelling, 2019, 65: 428-442. doi: 10.1016/j.apm.2018.08.028 [12] YOSHIDA K, SADAMOTO S, SETOYAMA Y, et al. Meshfree flat-shell formulation for evaluating linear buckling loads and mode shapes of structural plates[J]. Journal of Marine Science and Technology, 2017, 22(3): 501-512. doi: 10.1007/s00773-017-0433-2 [13] ZOU R D, FOSTER C G. Simple solution for buckling of orthotropic circular cylindrical shells[J]. Thin-Walled Structures, 1995, 22(3): 143-158. doi: 10.1016/0263-8231(94)00026-V [14] 张俊霖, 倪一文, 李庆东, 等. 吸湿老化影响下天然纤维增强复合圆柱壳屈曲分析的辛方法[J]. 应用数学和力学, 2021, 42(12): 1238-1247. doi: 10.21656/1000-0887.420018ZHANG Junlin, NI Yiwen, LI Qingdong, et al. A symplectic approach for buckling analysis of natural fiber reinforced composite shells under hygrothermal aging[J]. Applied Mathematics and Mechanics, 2021, 42(12): 1238-1247. (in Chinese) doi: 10.21656/1000-0887.420018 [15] 桂夷斐, 马建敏. 弹性介质中受轴向冲击载荷作用的圆柱壳的屈曲临界载荷计算分析[J]. 应用数学和力学, 2020, 41(4): 353-366. doi: 10.21656/1000-0887.400137GUI Yifei, MA Jianmin. Buckling critical load calculation and analysis of axially impacted cylindrical shells embedded in elastic media[J]. Applied Mathematics and Mechanics, 2020, 41(4): 353-366. (in Chinese) doi: 10.21656/1000-0887.400137 [16] SUN F, FAN H, ZHOU C, et al. Equivalent analysis and failure prediction of quasi-isotropic composite sandwich cylinder with lattice core under uniaxial compression[J]. Composite Structures, 2013, 101: 180-190. doi: 10.1016/j.compstruct.2013.02.005 [17] CHEN W, LIU D, KITIPORNCHAI S, et al. Bifurcation of pressurized functionally graded elastomeric hollow cylinders[J]. Composites (Part B): Engineering, 2017, 109: 259-276. doi: 10.1016/j.compositesb.2016.10.063 [18] REDDY J, STARNES J. General buckling of stiffened circular cylindrical-shells according to a layerwise theory[J]. Computers & Structures, 1993, 49(4): 605-616. [19] SHADMEHRI F, HOA S, HOJJATI M. The effect of displacement field on bending, buckling, and vibration of cross-ply circular cylindrical shells[J]. Mechanics of Advanced Materials and Structures, 2014, 21(1): 14-22. doi: 10.1080/15376494.2012.677102 [20] LI R, ZHENG X, WANG H, et al. New analytic buckling solutions of rectangular thin plates with all edges free[J]. International Journal of Mechanical Sciences, 2018, 144: 67-73. doi: 10.1016/j.ijmecsci.2018.05.041 [21] LI R, ZHENG X, WANG P, et al. New analytic free vibration solutions of orthotropic rectangular plates by a novel symplectic approach[J]. Acta Mechanica, 2019, 230(9): 3087-3101. doi: 10.1007/s00707-019-02448-1 [22] 王海阳. 矩形板屈曲问题的若干新解析解研究[D]. 硕士学位论文. 大连: 大连理工大学, 2019.WANG Haiyang. New analytical buckling solutions of rectangular plates[D]. Master Thesis. Dalian: Dalian University of Technology, 2019. (in Chinese) [23] DONNELL L. A new theory for the buckling of thin cylinders under axial compression and bending[J]. Trans ASME, 1934, 13: 795-806. [24] 姚伟岸, 钟万勰. 辛弹性力学[M]. 北京: 高等教育出版社, 2002.YAO Weian, ZHONG Wanxie. Symplectic Elasticity[M]. Beijing: Higher Education Press, 2002. (in Chinese) [25] ZHENG X, NI Z, XU D, et al. New analytic buckling solutions of non-Lévy-type cylindrical panels within the symplectic framework[J]. Applied Mathematical Modelling, 2021, 98: 398-415. doi: 10.1016/j.apm.2021.05.017 [26] CRAWLEY E. Natural-modes of graphite-epoxy cantilever plates and shells[J]. Journal of Composite Materials, 1979, 13: 195-205. doi: 10.1177/002199837901300302 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号