| [1] |

沈璐璐, 蔡方圆, 杨博. 功能梯度压电板柱面弯曲的弹性力学解[J]. 应用数学和力学, 2023, 44(3): 272-281. doi: 10.21656/1000-0887.430224SHEN Lulu, CAI Fangyuan, YANG Bo. Elasticity solutions for cylindrical bending of functionally graded piezoelectric material plates[J]. Applied Mathematics and Mechanics, 2023, 44(3): 272-281. (in Chinese) doi: 10.21656/1000-0887.430224

|

| [2] |

LORD H W, SHULMAN Y. A generalized dynamical theory of thermoelasticity[J]. Journal of the Mechanics and Physics of Solids, 1967, 15(5): 299-309. doi: 10.1016/0022-5096(67)90024-5

|

| [3] |

GREEN A E, LINDSAY K. Thermoelasticity[J]. Journal of elasticity, 1972, 2(1): 1-7. doi: 10.1007/BF00045689

|

| [4] |

GREEN A, NAGHDI P. On undamped heat waves in an elastic solid[J]. Journal of Thermal Stresses, 1992, 15(2): 253-264. doi: 10.1080/01495739208946136

|

| [5] |

段晓宇, 马永斌. 分数阶热弹理论下重力场对二维纤维增强介质的影响[J]. 应用数学和力学, 2021, 42(5): 452-459. doi: 10.21656/1000-0887.410125DUAN Xiaoyu, MA Yongbin. Effects of the gravity field on 2D fiber-reinforced media under the fractional order theory of thermoelasticity[J]. Applied Mathematics and Mechanics, 2021, 42(5): 452-459. (in Chinese) doi: 10.21656/1000-0887.410125

|

| [6] |

刘旭, 姚林泉. 热环境中旋转功能梯度纳米环板的振动分析[J]. 应用数学和力学, 2020, 41(11): 1224-1236. doi: 10.21656/1000-0887.410090LIU Xu, YAO Linquan. Vibration analysis of rotating functionally gradient nano annular plates in thermal environment[J]. Applied Mathematics and Mechanics, 2020, 41(11): 1224-1236. (in Chinese) doi: 10.21656/1000-0887.410090

|

| [7] |

ABD-ALLA A, ABO-DAHAB S, AHMED S, et al. Rayleigh surface wave propagation in an orthotropic rotating magneto-thermoelastic medium subjected to gravity and initial stress[J]. Mechanics of Advanced Materials and Structures, 2020, 27(16): 1400-1411. doi: 10.1080/15376494.2018.1512019

|

| [8] |

SHARMA J N, PAL M. Propagation of Lamb waves in a transversely isotropic piezothermoelastic plate[J]. Journal of Sound & Vibration, 2004, 270(4/5): 587-610.

|

| [9] |

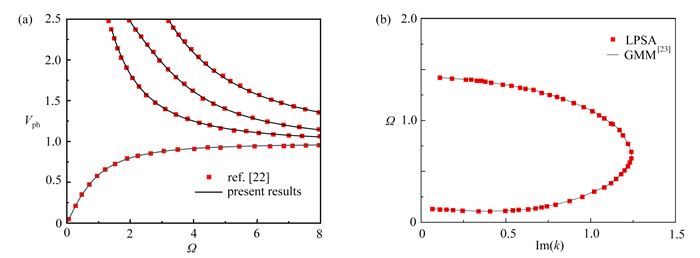

王现辉, 李方琳, 刘宇建, 等. 板中热弹波传播: 一种改进的勒让德多项式方法[J]. 力学学报, 2020, 52(5): 1277-1285. https://www.cnki.com.cn/Article/CJFDTOTAL-LXXB202005007.htmWANG Xianhui, LI Fanglin, LIU Yujian, et al. Thermoelastic wave propagation in plates: an improved Legendre polynomial approach[J]. Chinese Journal of Theoretical and Applied Mechanics, 2020, 52(5): 1277-1285. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-LXXB202005007.htm

|

| [10] |

PENG W, CHEN L, HE T. Nonlocal thermoelastic analysis of a functionally graded material microbeam[J]. Applied Mathematics and Mechanics, 2021, 42(6): 855-870. doi: 10.1007/s10483-021-2742-9

|

| [11] |

HEYDARPOUR Y, MALEKZADEH P, DIMITRI R, et al. Thermoelastic analysis of functionally graded cylindrical panels with piezoelectric layers[J]. Applied Sciences, 2020, 10(4): 1397. doi: 10.3390/app10041397

|

| [12] |

KHOSHGOFTAR M, ARANI A G, AREFI M. Thermoelastic analysis of a thick walled cylinder made of functionally graded piezoelectric material[J]. Smart Materials and Structures, 2009, 18(11): 115007. doi: 10.1088/0964-1726/18/11/115007

|

| [13] |

DAI H L, JIANG H J. Analytical study for electromagnetothermoelastic behavior of a functionally graded piezoelectric solid cylinder[J]. Mechanics of Advanced Materials and Structures, 2013, 20(10): 811-818. doi: 10.1080/15376494.2012.676715

|

| [14] |

OOTAO Y, AKAI T, TANIGAWA Y. Transient piezothermoelastic analysis for a functionally graded thermopiezoelectric hollow cylinder[J]. Journal of Thermal Stresses, 2008, 31(10): 935-955. doi: 10.1080/01495730802250508

|

| [15] |

AREFI M, RAHIMI G. General formulation for the thermoelastic analysis of an arbitrary structure made of functionally graded piezoelectric materials, based on the energy method[J]. Mechanical Engineering, 2011, 62: 221-235.

|

| [16] |

EL-NAGGAR A, KISHKA Z, ABD-ALLA A, et al. On the initial stress, magnetic field, voids and rotation effects on plane waves in generalized thermoelasticity[J]. Journal of Computational and Theoretical Nanoscience, 2013, 10(6): 1408-1417. doi: 10.1166/jctn.2013.2862

|

| [17] |

ZHU J, CHEN W, YE G, et al. Waves in fluid-filled functionally graded piezoelectric hollow cylinders: a restudy based on the reverberation-ray matrix formulation[J]. Wave Motion, 2013, 50(3): 415-427. doi: 10.1016/j.wavemoti.2012.10.006

|

| [18] |

LIU C, YU J, XU W, et al. Theoretical study of elastic wave propagation through a functionally graded micro-structured plate base on the modified couple-stress theory[J]. Meccanica, 2020, 55: 1153-1167. doi: 10.1007/s11012-020-01156-8

|

| [19] |

OTHMANI C, ZHANG H, LV C, et al. Orthogonal polynomial methods for modeling elastodynamic wave propagation in elastic, piezoelectric and magneto-electro-elastic composites: a review[J]. Composite Structures, 2022, 286: 115245.

|

| [20] |

ZHENG M, MA H, LYU Y, et al. Derivation of circumferential guided waves equations for a multilayered laminate composite hollow cylinder by state-vector and Legendre polynomial hybrid formalism[J]. Composite Structures, 2021, 255: 112950.

|

| [21] |

CAO X, JIN F, JEON I. Calculation of propagation properties of Lamb waves in a functionally graded material (FGM) plate by power series technique[J]. NDT & E International, 2011, 44(1): 84-92.

|

| [22] |

SHATALOV M Y, EVERY A G, YENWONG-FAI A S. Analysis of non-axisymmetric wave propagation in a homogeneous piezoelectric solid circular cylinder of transversely isotropic material[J]. International Journal of Solids & Structures, 2010, 46(3/4): 837-850.

|

| [23] |

WANG X H, LI F L, ZHANG B, et al. Wave propagation in thermoelastic inhomogeneous hollow cylinders by analytical integration orthogonal polynomial approach[J]. Applied Mathematical Modelling, 2021, 99: 57-80.

|

| [24] |

GUHA S, SINGH A K. Plane wave reflection/transmission in imperfectly bonded initially stressed rotating piezothermoelastic fiber-reinforced composite half-spaces[J]. European Journal of Mechanics A: Solids, 2021, 88: 104242.

|

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号