| [1] |

CUI Y J, WANG B L, WANG K F, et al. Power output evaluation of a porous annular thermoelectric generator for waste heat harvesting[J]. International Journal of Heat and Mass Transfer, 2019, 137: 979-989. doi: 10.1016/j.ijheatmasstransfer.2019.03.157

|

| [2] |

CUI Y J, WANG B L, WANG K F, et al. Fracture mechanics analysis of delamination in a thermoelectric pn-junction sandwiched by an insulating layer[J]. Applied Mathematics and Mechanics (English Edition), 2018, 39(10): 1477-1484. doi: 10.1007/s10483-018-2379-8

|

| [3] |

CUI Y J, WANG B L, WANG K F, et al. Theoretical model of fatigue crack growth of a thermoelectric pn-junction bonded to an elastic substrate[J]. Mechanics of Materials, 2020, 151: 103623. doi: 10.1016/j.mechmat.2020.103623

|

| [4] |

SOLEIMANI Z, ZORAS S, CERANIC B, et al. A comprehensive review on the output voltage/power of wearable thermoelectric generators concerning their geometry and thermoelectric materials[J]. Nano Energy, 2021, 89(A): 106325.

|

| [5] |

LU Y, LI X, CAI K, et al. Enhanced-Performance PEDOT: PSS/Cu2Se-based composite films for wearable thermoelectric power generators[J]. ACS Applied Materials and Interfaces, 2021, 12: 631-638.

|

| [6] |

WANG L P, HU B L, ZHANG F Y, et al. A highly stable elastic electrode via direct covalent crosslinking for strain sensors[J]. Journal of Materials Chemistry C, 2023, 12: 4235-4242.

|

| [7] |

XIN B B, WANG L, FEBVRIER A L, et al. Mechanically flexible thermoelectric hybrid thin films by introduction of PEDOT: PSS in nanoporous Ca3Co4O9[J]. ACS Omega, 2022, 7(27): 23988-23994. doi: 10.1021/acsomega.2c02875

|

| [8] |

KARALIS G, TZOUNIS L, MYTAFIDES C K, et al. A high performance flexible and robust printed thermoelectric generator based on hybridized Te nanowires with PEDOT: PSS[J]. Applied Energy, 2021, 294: 117004. doi: 10.1016/j.apenergy.2021.117004

|

| [9] |

LIU J, LIU Q, LIN S P, et al. Wearable thermoelectric generators: materials, structures, fabrications, and applications[J]. Physica Status Solidi-Rapid Research Letters, 2023, 17(7): 2200502. doi: 10.1002/pssr.202200502

|

| [10] |

RAMESH V P, SARGOLZAEIAVAL Y, NEUMANN T, et al. Flexible thermoelectric generator with liquid metal interconnects and low thermal conductivity silicone filler[J]. NPJ Flexible Electronics, 2021, 5(1): 5. doi: 10.1038/s41528-021-00101-3

|

| [11] |

CUI Y J, LIU C, WANG K F, et al. Effect of negative Poisson's ratio architecture on fatigue life and output power of flexible wearable thermoelectric generators[J]. Engineering Fracture Mechanics, 2023, 281: 109142. doi: 10.1016/j.engfracmech.2023.109142

|

| [12] |

CUI Y J, WANG B L, WANG K F, et al. An analytical model to evaluate influence of negative Poisson's ratio architecture on fatigue life and energy conversion performance of wearable thermoelectric generator[J]. International Journal of Solids and Structures, 2022, 258: 112000. doi: 10.1016/j.ijsolstr.2022.112000

|

| [13] |

SELVAN K V, HASAN M N, ALI S M, et al. State-of-the-art reviews and analyses of emerging research findings and achievements of thermoelectric materials over the past years[J]. Journal of Electronic Materials, 2019, 48: 745-777. doi: 10.1007/s11664-018-06838-4

|

| [14] |

WEI W, LI J W, ZHANG H T, et al. Macrostructural influence on the thermoelectric properties of SiC ceramics[J]. Scripta Materialia, 2007, 57(12): 1081-1084. doi: 10.1016/j.scriptamat.2007.08.036

|

| [15] |

WANG N, HE H, LI X, et al. Thermoelectric properties of Nb-doped SrTiO3 ceramics enhanced by potassium titanate nanowires addition[J]. Journal of the Ceramic Society of Japan, 2010, 118: 1098-1101.

|

| [16] |

CUI Y J, WANG K F, WANG B L, et al. A comprehensive analysis of delamination and thermoelectric performance of thermoelectric pn-junctions with temperature-dependent material properties[J]. Composite Structures, 2019, 229: 111484. doi: 10.1016/j.compstruct.2019.111484

|

| [17] |

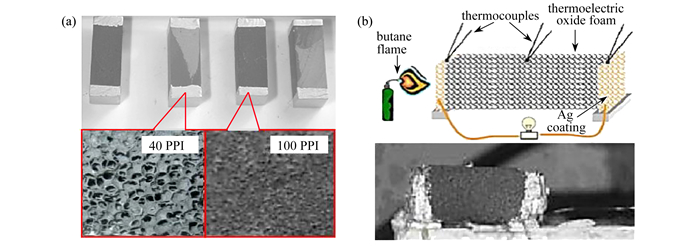

REDDY E S, NOUDEM J G, GOUPIL C. Open porous foam oxide thermoelectric elements for hot gases and liquid environments[J]. Energy Conversion and Management, 2007, 48(4): 1251-1254. doi: 10.1016/j.enconman.2006.09.025

|

| [18] |

NOUDEM J G, LEMONNIER S, PREVEL M, et al. Thermoelectric ceramics for generators[J]. Journal of the European Ceramic Society, 2008, 28(1): 41-48. doi: 10.1016/j.jeurceramsoc.2007.05.012

|

| [19] |

NITHYANANDAM K, MAHAJAN R L. Evaluation of metal foam based thermoelectric generators for automobile waste heat recovery[J]. International Journal of Heat and Mass Transfer, 2018, 122: 877-883. doi: 10.1016/j.ijheatmasstransfer.2018.02.029

|

| [20] |

YILBAS B S, AKHTAR S S, SAHIN A Z. Thermal and stress analyses in thermoelectric generator with tapered and rectangular pin configurations[J]. Energy, 2016, 114: 52-63. doi: 10.1016/j.energy.2016.07.168

|

| [21] |

SHITTU S, LI G Q, ZHAO X D, et al. High performance and thermal stress analysis of a segmented annular thermoelectric generator[J]. Energy Conversion and Management, 2019, 184: 180-193. doi: 10.1016/j.enconman.2019.01.064

|

| [22] |

朱明明, 李联和. 含正三角形孔口热电材料的断裂力学分析[J]. 应用数学和力学, 2021, 42(6): 656-664. doi: 10.21656/1000-0887.410232ZHU Mingming, LI Lianhe. Fracture mechanics analysis of thermoelectric materials with equilateral triangle holes[J]. Applied Mathematics and Mechanics, 2021, 42(6): 656-664. (in Chinese) doi: 10.21656/1000-0887.410232

|

| [23] |

徐华, 曹政, 邹云鹏, 等. 裂纹面分布加载裂尖SIFs分析的广义参数Williams单元[J]. 应用数学和力学, 2022, 43(7): 752-760. doi: 10.21656/1000-0887.420317XU Hua, CAO Zheng, ZOU Yunpeng, et al. Williams elements with generalized degrees of freedom for crack tip SIFs analysis under crack surface distributed loading[J]. Applied Mathematics and Mechanics, 2022, 43(7): 752-760. (in Chinese) doi: 10.21656/1000-0887.420317

|

| [24] |

CUI Y J, WANG B L, LI J E, et al. Performance evaluation and lifetime prediction of a segmented photovoltaic-thermoelectric hybrid system[J]. Energy Conversion and Management, 2020, 211: 112744. doi: 10.1016/j.enconman.2020.112744

|

| [25] |

TADA H, PAUL C, GEORGE R. The Stress Analysis of Cracks Handbook[M]. 3rd ed. ASME Press, 2000.

|

| [26] |

张晓敏, 万凌, 严波, 等. 断裂力学[M]. 北京: 清华大学出版社, 2012: 142-143.ZHANG Xiaomin, WAN Ling, YAN Bo, et al. Fracture Mechanics[M]. Beijing: Tsinghua University Press, 2012: 142-143. (in Chinese)

|

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号