Stress Analysis and Evaluation of the High-Temperature High-Pressure Wellbore Hole Simulator

-

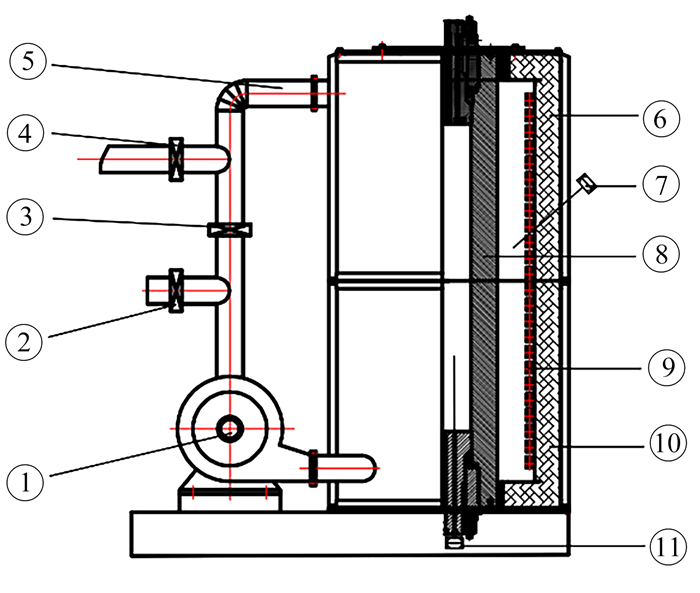

摘要: 模拟井筒是用于模拟油田井下高温高压环境的实验装置,为高温高压厚壁容器. 基于热力学及大涡模拟(LES)理论,建立了模拟井筒温度场物理方程. 基于热弹性力学理论,建立了热应力物理方程. 采用投影法求解温度场控制方程,采用梯形法数值积分求解热应力控制方程,给出了控制方程的离散格式. 通过虚拟密度法对流固耦合传热进行求解,根据应力叠加原理对模拟井筒热应力和压应力及其耦合作用进行了数值求解分析. 研究结果表明:设计壁厚最小值为0.18 m的模拟井筒,强度能够满足在400 ℃加热环境、内部加压220 MPa工作参数下进行高温高压实验. 通过实验验证了所建立的数学模型与数值求解方法的正确性,为高温高压厚壁容器设计提供了理论依据.Abstract: The wellbore hole simulator as a high-temperature high-pressure thick-walled container, is an experimental device used to simulate the high-temperature high-pressure downhole environment of oilfield. Based on thermodynamics and the large eddy simulation (LES) theory, a physical equation was established. The projection method was applied to solve the temperature field governing equation, and the trapezoidal-rule numerical integration was used to solve the thermal stress governing equation. The discrete scheme for the governing equation was given. The fluid-structure-interaction heat transfer was solved with the virtual density method, and the thermal stress, the pressure stress and their coupling effect of the wellbore hole simulator were numerically analyzed under the principle of stress superimposition. The research results indicate that, the wellbore hole simulator with a minimum wall thickness of 0.18 m could meet the strength requirements for high-temperature high-pressure experiments with 400 ℃ and 220 MPa working parameters. The experiments prove the correctness of the established mathematical model and the numerical solution methods, providing a theoretical basis for the design of thick-walled cylinder containers under high-temperature high-pressure conditions.

-

Key words:

- thermal stress /

- large eddy simulation /

- projection method /

- stress coupling /

- strength analysis

-

表 1 PcrNi3MoVA Ⅳ的力学参数

Table 1. Mechanical parameters of PcrNi3MoVA Ⅳ

temperature T/℃ elastic modulus E/GPa yield strength σs/GPa Poisson’s ratio ν linear expansion coefficient β/℃-1 20 206 1.40 0.3 1.06×10-5 200 192 1.33 400 175 1.15 600 153 0.92 800 125 0.68 -

[1] SASSINE N, DONZÉ F V, HARTHONG B, et al. Thermal stress numerical study in granular packed bed storage tank[J]. Granular Matter, 2018, 20(3): 44. doi: 10.1007/s10035-018-0817-y [2] TALER J, DZIERWA P, JAREMKIEWICZ M. Thermal stress monitoring in thick-walled pressure components based on the solutions of the inverse heat conduction problems[J]. Multidiscipline Modeling in Materials and Structures, 2018, 41(10): 1501-1524. [3] KUMAR A E, NAVURI K, MANIDEEP K, et al. Effect of thermal environment on buckling of thick cylinder subjected to combined axial compressive and external pressure loads[J]. Materials Today: Proceedings, 2018, 5(2): 3298-3305. doi: 10.1016/j.matpr.2017.11.572 [4] 赵玉峰, 刘泓杉. 非均匀长圆柱超导体的热应力分析[J]. 兰州理工大学学报, 2018, 44(6): 167-172. doi: 10.3969/j.issn.1673-5196.2018.06.031ZHAO Yufeng, LIU Hongshan. Analysis of thermal stress in inhomogeneous long cylindrical superco-nductor[J]. Journal of Lanzhou University of Technology, 2018, 44(6): 167-172. (in Chinese) doi: 10.3969/j.issn.1673-5196.2018.06.031 [5] 李若愚, 王天宏. 薄板热力耦合的屈曲分析[J]. 应用数学和力学, 2020, 41(8): 877-886. doi: 10.21656/1000-0887.400308LI Ruoyu, WANG Tianhong. Thermo-mechanical buckling analysis of thin plates[J]. Applied Mathematics and Mechanics, 2020, 41(8): 877-886. (in Chinese) doi: 10.21656/1000-0887.400308 [6] 申彪, 廖振强, 李洪强, 等. 厚壁圆筒热-结构耦合应力分析[J]. 弹箭与制导学报, 2019, 39(3): 49-52.SHEN Biao, LIAO Zhenqiang, LI Hongqiang, et al. Calculating for thermo-mechanical coupling stress in thick wall cylinders[J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2019, 39(3): 49-52. (in Chinese) [7] ALMASI A, BAGHANI M, MOALLEMI A, et al. Investigation on thermal stresses in FGM hyperelastic thick-walled cylinders[J]. Journal of Thermal Stresses, 2018, 41(2): 204-221. doi: 10.1080/01495739.2017.1395719 [8] 杨阳, 王凯模, 沈火明, 等. 温差影响下的局部滑移接触行为的研究[J]. 应用数学和力学, 2023, 44(2): 123-132. doi: 10.21656/1000-0887.430334YANG Yang, WANG Kaimo, SHEN Huoming, et al. Research on partial slip contact behaviors under temperature effects[J]. Applied Mathematics and Mechanics, 2023, 44(2): 123-132. (in Chinese) doi: 10.21656/1000-0887.430334 [9] MANTHENA V R, KEDAR G D. Transient thermal stress analysis of a functionally graded thick hollow cylinder with temperature-dependent material properties[J]. Journal of Thermal Stresses, 2018, 41(5): 568-582. doi: 10.1080/01495739.2017.1402669 [10] TAKUMA K, JUNNOSUKE O, ATSUKI K. Large eddy simulation of turbulent natural convection between symmetrically heated vertical parallel plates for water[J]. International Journal of Heat and Mass Transfer, 2016, 101: 870-877. doi: 10.1016/j.ijheatmasstransfer.2016.04.083 [11] HANAE D, STÉPHANE A, MOHAMED L L. Large eddy simulation of turbulent natural convection in an inclined tall cavity[J]. Numerical Heat Transfer (Part A): Applications, 2018, 74(4): 1175-1189. doi: 10.1080/10407782.2018.1509602 [12] ORTIZ A V, KOLOSZAR L, PLANQUART P. Large eddy simulations on a natural convection boundary layer at Pr=0.1 and 0.025[J]. Nuclear Engineering and Design, 2019, 353: 1-8. [13] 冯志鹏, 张毅雄, 臧峰刚. 直管束流固耦合振动的数值模拟[J]. 应用数学和力学, 2013, 34(11): 1165-1172. doi: 10.3879/j.issn.1000-0887.2013.11.006FENG Zhipeng, ZHANG Yixiong, ZANG Fenggang. Numerical simulation of fluid-structure interaction for tube bundles[J]. Applied Mathematics and Mechanics, 2013, 34(11): 1165-1172. (in Chinese) doi: 10.3879/j.issn.1000-0887.2013.11.006 [14] 邓诗雨, 卢涛, 邓坚, 等. 液态铅铋合金湍流普朗特数及RANS模型优选[J]. 核动力工程, 2023, 44(2): 98-103.DENG Shiyu, LU Tao, DENG Jian, et al. Optimization of turbulent Prandtl numbers and RANS models for liquid lead-bismuth eutectic[J]. Nuclear Power Engineering, 2023, 44(2): 98-103. (in Chinese) [15] 刘淼儿, 任玉新, 张涵信. 求解不可压Navier-Stokes方程的三阶精度投影方法[J]. 清华大学学报(自然科学版), 2005, 44(2): 285-288.LIU Miaoer, REN Yuxin, ZHANG Hanxin. Third-order projection method for solving the incompressible Navier-Stokes equations[J]. Journal of Tsinghua University (Science and Technology), 2023, 44(2): 285-288. (in Chinese) [16] HAFIZ U A, HODA A, ASRAR W. A numerical investigation of explicit pressure-correction projection methods for incompressible flows[J]. Engineering Applications of Computational Fluid Mechanics, 2019, 9(1): 50-65. [17] TABBAKH Z, SEAID M, ELLAIA R, et al. A local radial basis function projection method for incompressible flows in water eutrophication[J]. Engineering Analysis With Boundary Elements, 2019, 106: 528-540. [18] 超高压容器: GB/T 34019—2017[S]. 北京: 中国标准出版社, 2017.Ultra-high pressure vessels: GB/T 34019 —2017[S]. Beijing: Standards Press of China, 2017. (in Chinese)) -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号