Dynamic Response and Energy Absorption Performances of Multi-Walled Tube Reinforced Aluminum Foam Structure

-

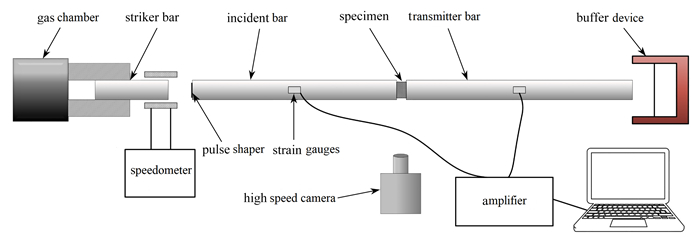

摘要: 为了提高泡沫铝吸能性能,该文将多壁管及泡沫铝材料相结合,提出了一种多壁管增强泡沫铝结构. 通过Hopkinson压杆试验以及有限元分析软件ABAQUS/Explicit,研究了泡沫铝、多壁管及其增强泡沫铝的动态压溃特性. 对比分析了泡沫铝复合多壁管前后的变形模式、吸能性能,并讨论了多壁管增强泡沫铝的应变率效应以及应变率对多壁管增强泡沫铝耦合增强作用的影响. 研究表明,有限元仿真能够较好地模拟试验结果. 测试结果表明所采用的泡沫铝应变率效应不明显,而多壁管及多壁管增强泡沫铝应变率效应较为明显,在高应变率下其能量吸收可进一步提升. 在动态冲击条件下,多壁管增强泡沫铝峰值力相比单一多壁管或泡沫有明显的耦合增强,其能量吸收相比单一多壁管及泡沫铝能量吸收之和提升10.34%. 通过研究多壁管增强泡沫铝的动态压溃特性,可为承载吸能构件的应用提供依据和参考.Abstract: In order to improve the energy absorption performance of the aluminum foam, a multi-wall tube reinforced aluminum foam was proposed. The dynamic crushing characteristics of the aluminum foam, the multi-wall tube, and the multi-wall tube reinforced aluminum foam were studied by Hopkinson pressure rod tests & finite element analysis with software ABAQUS/Explicit. The deformation mode and energy absorption of the aluminum foam was compared with those of the multi-wall tube reinforced aluminum foam, with the strain rate effect on the coupling enhancement discussed. The results show that, the finite element analysis can simulate the test results well. The strain rate effect on the aluminum foam is not obvious, while that on the multi-walled tube and the multi-wall tube reinforced aluminum foam is considerably obvious, and the energy absorption improves with higher strain rates. Under the dynamic impact condition, the peak strength of the multi-walled tube reinforced aluminum foam has obvious coupling enhancement compared with that of the multi-walled tube or the aluminum foam, and the corresponding energy absorption of the former increases by 10.34% over the sum of those of the latter ones. The study on dynamic crushing characteristics of the multi-walled tube reinforced aluminum foam provides a reference for the application of energy-absorbing load-carrying components.

-

Key words:

- multiwalled tube /

- aluminum foam /

- dynamic characteristic /

- strain rate /

- coupling enhancement

-

表 1 动态冲击试验试样参数

Table 1. Specimen parameters for dynamic impact tests

specimen number height h/mm diameter d1/mm diameter d2/mm thickness t/mm mass M/g AF-9 40 - 56.78 - 40.4 AF-5 40.015 - 56.715 - 43.2 AF-1 40.04 - 56.73 - 43.8 EMWT-2 40.00 31.80 31.80 1 16 EMWT-3 40.08 31.92 31.92 1 16.2 EMWT-1 40.02 31.99 31.99 1 16.2 EMWT-4 40.08 31.95 31.95 1 16.2 MWTRF-3 40.16 31.80 56.86 1 59 MWTRF-4 40.092 31.92 56.77 1 58.4 MWTRF-1 40.08 31.99 56.79 1 60.2 MWTRF-5 40.056 31.95 56.78 1 58.2 MWTRF-6 40.204 56.85 59.2 表 2 试验设置

Table 2. The test setup

sample speed 4 m/s 9 m/s 13 m/s 18 m/s AF √ √ - - EMWT √ √ - - MWTRF √ √ √ √ 表 3 材料参数

Table 3. Material parameters

material density ρ/(kg/m3) Young’s modulus E/MPa yield strength σy/MPa tensile strength σt/MPa Poisson’s ratio ν Al6061 2 700 70 000 190 230 0.3 Al foam 400 500 6.09 - 0.11 -

[1] AL-SAHLANI K, BROXTERMANN S, LELL D, et al. Effects of particle size on the microstructure and mechanical properties of expanded glass-metal syntactic foams[J]. Materials Science and Engineering A: Structural Materials: Properties, Microstructure and Processing, 2018, 728: 80-87. doi: 10.1016/j.msea.2018.04.103 [2] CIARDIELLO R, DRZAL L T, BELINGARDI G. Effects of carbon black and graphene nano-platelet fillers on the mechanical properties of syntactic foam[J]. Composite Structures, 2017, 178: 9-19. doi: 10.1016/j.compstruct.2017.07.057 [3] MARX J, PORTANOVA M, RABIEI A. A study on blast and fragment resistance of composite metal foams through experimental and modeling approaches[J]. Composite Structures, 2018, 194: 652-661. doi: 10.1016/j.compstruct.2018.03.075 [4] ZHOU R, CROCKER M J. Sound transmission loss of foam-filled honeycomb sandwich panels using statistical energy analysis and theoretical and measured dynamic properties[J]. Journal of Sound and Vibration, 2010, 329(6): 673-686. doi: 10.1016/j.jsv.2009.10.002 [5] ASHBY M F, EVANS A, FLECK N A, et al. Metal foams: a design guide[J]. Applied Mechanics Reviews, 2002, 23(6): 119. [6] BANHART J. Manufacture, characterization and application of cellular metals and metal foams[J]. Progress in Materials Science, 2001, 46(6): 559-632. doi: 10.1016/S0079-6425(00)00002-5 [7] GUO Q, LI W B, YAO W J, et al. Mechanical properties and constitutive model applied to the high-speed impact of aluminum foam that considers its meso-structural parameters[J]. Materials, 2021, 14(20): 6206. doi: 10.3390/ma14206206 [8] BANHART J. Metal foams: production and stability[J]. Advanced Engineering Materials, 2006, 8(9): 781-794. doi: 10.1002/adem.200600071 [9] MOVAHEDI N, CONWAY S, BELOVA I V, et al. Influence of particle arrangement on the compression of functionally graded metal syntactic foams[J]. Materials Science and Engineering A: Structural Materials: Properties, Microstructure and Processing, 2019, 764: 138242. doi: 10.1016/j.msea.2019.138242 [10] YANG K M, YANG X D, HE C N, et al. Damping characteristics of Al matrix composite foams reinforced by in-situ grown carbon nanotubes[J]. Materials Letters, 2017, 209: 68-70. doi: 10.1016/j.matlet.2017.07.126 [11] DU Y, LI A B, ZHANG X X, et al. Enhancement of the mechanical strength of aluminum foams by SiC nanoparticles[J]. Materials Letters, 2015, 148: 79-81. doi: 10.1016/j.matlet.2015.02.066 [12] BHOGI S, NAMPOOTHIRI J, RAVI K R, et al. Influence of nano and micro particles on the expansion and mechanical properties of aluminum foams[J]. Materials Science and Engineering A: Structural Materials: Properties, Microstructure and Processing, 2017, 685: 131-138. doi: 10.1016/j.msea.2016.12.127 [13] DUARTE I, VENTURA E, OLHERO S, et al. A novel approach to prepare aluminium-alloy foams reinforced by carbon-nanotubes[J]. Materials Letters, 2015, 160: 162-166. doi: 10.1016/j.matlet.2015.07.115 [14] YANG K M, YANG X D, LIU E Z, et al. Elevated temperature compressive properties and energy absorption response of in-situ grown CNT-reinforced Al composite foams[J]. Materials Science and Engineering A: Structural Materials: Properties, Microstructure and Processing, 2017, 690: 294-302. doi: 10.1016/j.msea.2017.03.004 [15] LINUL E, MARSAVINA L, LINUL P A, et al. Cryogenic and high temperature compressive properties of metal foam matrix composites[J]. Composite Structures, 2019, 209: 490-498. doi: 10.1016/j.compstruct.2018.11.006 [16] 杨旭东, 许佳丽, 邹田春, 等. 泡沫铝填充金属薄壁管复合结构的研究进展[J]. 材料导报, 2019, 33(21): 111-117.YANG Xudong, XU Jiali, ZOU Tianchun, et al. Advances in the composite structure of aluminum foam filled metal thin-walled tube[J]. Materials Reports, 2019, 33(21): 111-117. (in Chinese) [17] YAN L L, ZHAO Z Y, HAN B, et al. Tube enhanced foam: a novel way for aluminum foam enhancement[J]. Materials Letters, 2018, 227: 70-73. doi: 10.1016/j.matlet.2018.04.115 [18] ZHANG Z J, HUANG L, LI B, et al. Design of a novel multi-walled tube-reinforced aluminum foam for energy absorption[J]. Composite Structures, 2021, 276: 114584. doi: 10.1016/j.compstruct.2021.114584 [19] ZHANG Z J, WANG J, WANG Y J, et al. Elevated temperature axial crushing performance of multi-walled tube-reinforced aluminum foam[J]. Thin-Walled Structures, 2023, 185: 110582. doi: 10.1016/j.tws.2023.110582 [20] YIN H F, XIAO Y Y, WEN G L. Multi-objective robust optimization of foam-filled bionic thin-walled structures[J]. Thin-Walled Structures, 2016, 109: 332-343. doi: 10.1016/j.tws.2016.10.011 [21] CHEN W G, WIERZBICKI T. Relative merits of single-cell, multi-cell and foam-filled thin-walled structures in energy absorption[J]. Thin-Walled Structures, 2001, 39(4): 287-306. doi: 10.1016/S0263-8231(01)00006-4 [22] SUN Y, LI Q M. Dynamic compressive behavior of cellular materials: a review of phenomenon, mechanism and modelling[J]. International Journal of Impact Engineering, 2018, 112: 74-115. doi: 10.1016/j.ijimpeng.2017.10.006 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号