Study on Constitutive Relations and Boundary Value Problems of Granular Materials Based on Artificial Neural Networks

-

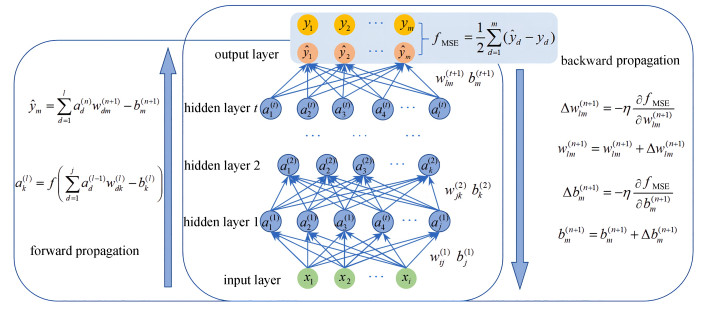

摘要: 颗粒材料被广泛运用于工程实践中,通过数值模拟解决颗粒材料有关的边值问题,对于指导工程实践具有重要意义.通过应用人工神经网络算法,将基于离散颗粒模型的离散单元法与基于连续介质模型的有限单元法有机结合以求解颗粒材料边值问题,形成了一套新的、完整的模型及解决方案,即细观模型离线计算的细-宏观两尺度模型及求解系统.具体为:先基于离散单元法获取颗粒材料的主应力、主应变以及对应的应力-应变矩阵等数据;再将获取的数据利用人工神经网络算法构建在主空间上描述颗粒材料本构关系的人工神经网络模型;最后,通过用户自定义材料子程序UMAT将人工神经网络模型导入ABAQUS中求解颗粒材料边值问题.通过平板受压以及边坡稳定性数值试验,并与经典弹塑性模型求解结果进行对比,表明了训练后的人工神经网络模型能够有效地反映颗粒材料的本构关系,并能够运用于实践求解边值问题,验证了该求解方案的可行性.Abstract: Granular materials are widely used in engineering practice, where the numerical simulation of boundary value problems related to granular materials is of great significance. By the artificial neural network algorithm, the discrete element method based on discrete particle models and the finite element method based on continuous models were organically combined to solve the boundary value problems of granular materials. A new and complete model and the solution were formed, namely, the micro-macroscopic 2-scale model and its solution system for offline calculation of the meso model. Specifically, the principal stress, the principal strain, and the corresponding stress-strain matrix of a granular material were first obtained based on the discrete element method. Then an artificial neural network model was built in the main space to describe the constitutive relationship of the granular material by an artificial neural network algorithm. Finally, the artificial neural network model was imported into ABAQUS to solve the boundary value problem of the granular material with the user-defined material subroutine UMAT. Through the numerical tests of plate compression and slope stability, and the comparison with the solution results of the classical elastoplastic model, it is seen that the trained artificial neural network model can effectively reflect the constitutive relationship of granular materials, and can be used in practice to solve boundary value problems. The results show the feasibility of the solution scheme.

-

表 1 样本模型参数

Table 1. Sample model parameters

parameter value ball normal stiffness Kn/(N/m) 108 shear stiffness Ks/(N/m) 5×107 friction coefficient 0.0(before servo) / 0.3(after servo) porosity 0.15 density ρ/(kg/m3) 2 600 damping coefficient 0.7 wall normal stiffness Kn/(N/m) 109 shear stiffness Ks/(N/m) 5×108 friction coefficient 0 表 2 神经网络结构参数

Table 2. Structural parameters of the neural networks

neural network 1 neural network 2 input data ε1, ε2 ε1, ε2 output data σ1 , σ2 C1111 ,C1122 ,C2211 ,C2222 number of hidden layers 3 4 number of neurons in hidden layer 1 10 10 number of neurons in hidden layer 2 10 10 number of neurons in hidden layer 3 10 10 number of neurons in hidden layer 4 10 learning rate 0.1 0.05 number of epochs 200 000 200 000 -

[1] CUNDALL P A. The measurement and analysis of accelerations in rock slopes[D]. London: University of London, 1971. [2] CUNDALL P A, STRACK O D. A discrete numerical model for granular assemblies[J]. Geotechnique, 1979, 29(1): 47-65. doi: 10.1680/geot.1979.29.1.47 [3] 李典哲, 刘璐, 季顺迎. 基于扩展多面体组合单元的非规则颗粒材料离散元方法[J]. 应用数学与力学, 2023, 44(7): 769-783. https://www.cnki.com.cn/Article/CJFDTOTAL-YYSX202307002.htmLI Dianzhe, LIU Lu, JI Shunying. A discrete element method for irregular granular materials based on multi-dilated polyhedron elements[J]. Applied Mathematics and Mechanics, 2023, 44(7): 769-783. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YYSX202307002.htm [4] XIU C, CHU X. A micromechanics-based gradient model and the effect of high-order stress and particle rolling on localizations for granular materials[J]. Granular Matter, 2017, 19: 1-21. doi: 10.1007/s10035-016-0682-5 [5] CHU X, YU C, XIU C, et al. Two scale modeling of behaviors of granular structure: size effects and displacement fluctuations of discrete particle assembly[J]. Structural Engineering and Mechanics, 2015, 55(2): 315-334. doi: 10.12989/sem.2015.55.2.315 [6] JANSSEN H. Tests on grain pressure silos[J]. Zeitschrift des Vereines Deutscher Ingenieure, 1895, 39(35): 1045. [7] ROBERTS I I. Determination of the vertical and lateral pressures of granular substances[J]. Proceedings of the Royal Society of London, 1883, 36(228/231): 225-240. [8] HONG D C, QUINN P V, LUDING S. Reverse Brazil nut problem: competition between percolation and condensation[J]. Physical Review Letters, 2001, 86(15): 3423. doi: 10.1103/PhysRevLett.86.3423 [9] LUDING S, CLÉMENT E, RAJCHENBACH J, et al. Simulations of pattern formation in vibrated granular media[J]. Europhysics Letters, 1996, 36(4): 247. doi: 10.1209/epl/i1996-00217-9 [10] VANEL L, CLAUDIN P, BOUCHAUD J P, et al. Stresses in silos: comparison between theoretical models and new experiments[J]. Physical Review Letters, 2000, 84(7): 1439. doi: 10.1103/PhysRevLett.84.1439 [11] 刘嘉, 冯德銮. 考虑土颗粒微细观运动的多尺度耦合有限元分析方法[J]. 岩土力学, 2021, 42(4): 1186-1199. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202104032.htmLIU Jia, FENG Deluan. A multi-scale coupling finite element method based on the microscopic soil particle motions[J]. Rock and Soil Mechanics, 2021, 42(4): 1186-1199. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202104032.htm [12] MUNJIZA A. The Combined Finite-Discrete Element Method[M]. Chichester: John Wiley & Sons, 2004. [13] MUNJIZA A, OWEN D, BICANIC N. A combined finite-discrete element method in transient dynamics of fracturing solids[J]. Engineering Computations, 1995, 12(2): 145-174. doi: 10.1108/02644409510799532 [14] MASI F, STEFANOU I, VANNUCCI P, et al. Thermodynamics-based artificial neural networks for constitutive modeling[J]. Journal of the Mechanics and Physics of Solids, 2021, 147: 104277. doi: 10.1016/j.jmps.2020.104277 [15] BENVENUTI L, KLOSS C, PIRKER S. Identification of DEM simulation parameters by artificial neural networks and bulk experiments[J]. Powder Technology, 2016, 291: 456-465. doi: 10.1016/j.powtec.2016.01.003 [16] ZHANG P, YIN Z Y, JIN Y F, et al. An AI-based model for describing cyclic characteristics of granular materials[J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2020, 44(9): 1315-1335. doi: 10.1002/nag.3063 [17] WANG M, QU T, GUAN S, et al. Data-driven strain-stress modelling of granular materials via temporal convolution neural network[J]. Computers and Geotechnics, 2022, 152: 105049. doi: 10.1016/j.compgeo.2022.105049 [18] QU T, DI S, FENG Y, et al. Towards data-driven constitutive modelling for granular materials via micromechanics-informed deep learning[J]. International Journal of Plasticity, 2021, 144: 103046. doi: 10.1016/j.ijplas.2021.103046 [19] KOHONEN T. An introduction to neural computing[J]. Neural Networks, 1988, 1(1): 3-16. doi: 10.1016/0893-6080(88)90020-2 [20] 瞿同明, 冯云田, 王孟琦, 等. 基于深度学习和细观力学的颗粒材料本构关系研究[J]. 力学学报, 2021, 53(9): 2404-2415. https://www.cnki.com.cn/Article/CJFDTOTAL-LXXB202109006.htmQU Tongming, FENG Yuntian, WANG Mengqi, et al. Constitutive relations of granular materials by integrating micromechanical knowledge with deep learning[J]. Chinese Journal of Theoretical and Applied Mechanics, 2021, 53(9): 2404-2415. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-LXXB202109006.htm [21] 周志华. 机器学习[M]. 北京: 清华大学出版社, 2016.ZHOU Zhihua. Machine Learning[M]. Beijing: Tsinghua University Press, 2016. (in Chinese) [22] GUAN S, QU T, FENG Y, et al. A machine learning-based multi-scale computational framework for granular materials[J]. Acta Geotechnica, 2023, 18: 1699-1720. doi: 10.1007/s11440-022-01709-z -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号