Lamination Design Optimization for Continuous Fiber Reinforced Composites of Variable Thicknesses

-

摘要:

由于具备高的比强度、比刚度,利用连续纤维增强复合材料代替传统金属材料以实现结构轻量化正受到设计者们的广泛关注。然而,结构的复杂性给复合材料的铺层设计与优化带来了很大的挑战。针对航空用复合材料铺层设计约束多的问题,通过逐步构建设计变量准确表达结构的铺层信息。基于经典遗传算法框架,结合各设计变量特点,定义了铺层优化算法中的遗传算子,通过引入“修复”策略保证了每一代解都能满足设计约束,分布在可行域区间内。最后利用精英保留策略提高了算法的局部寻优能力,可以降低复杂复合材料结构铺层设计的计算成本。通过解决经典benchmark问题并与已有优化结果的比较,验证了前述铺层优化算法的全局、局部寻优能力,为工程实际中的复合材料铺层设计优化提供了理论支撑。

-

关键词:

- 连续纤维增强复合材料 /

- 铺层设计优化 /

- 遗传算法 /

- “修复”策略 /

- 寻优能力

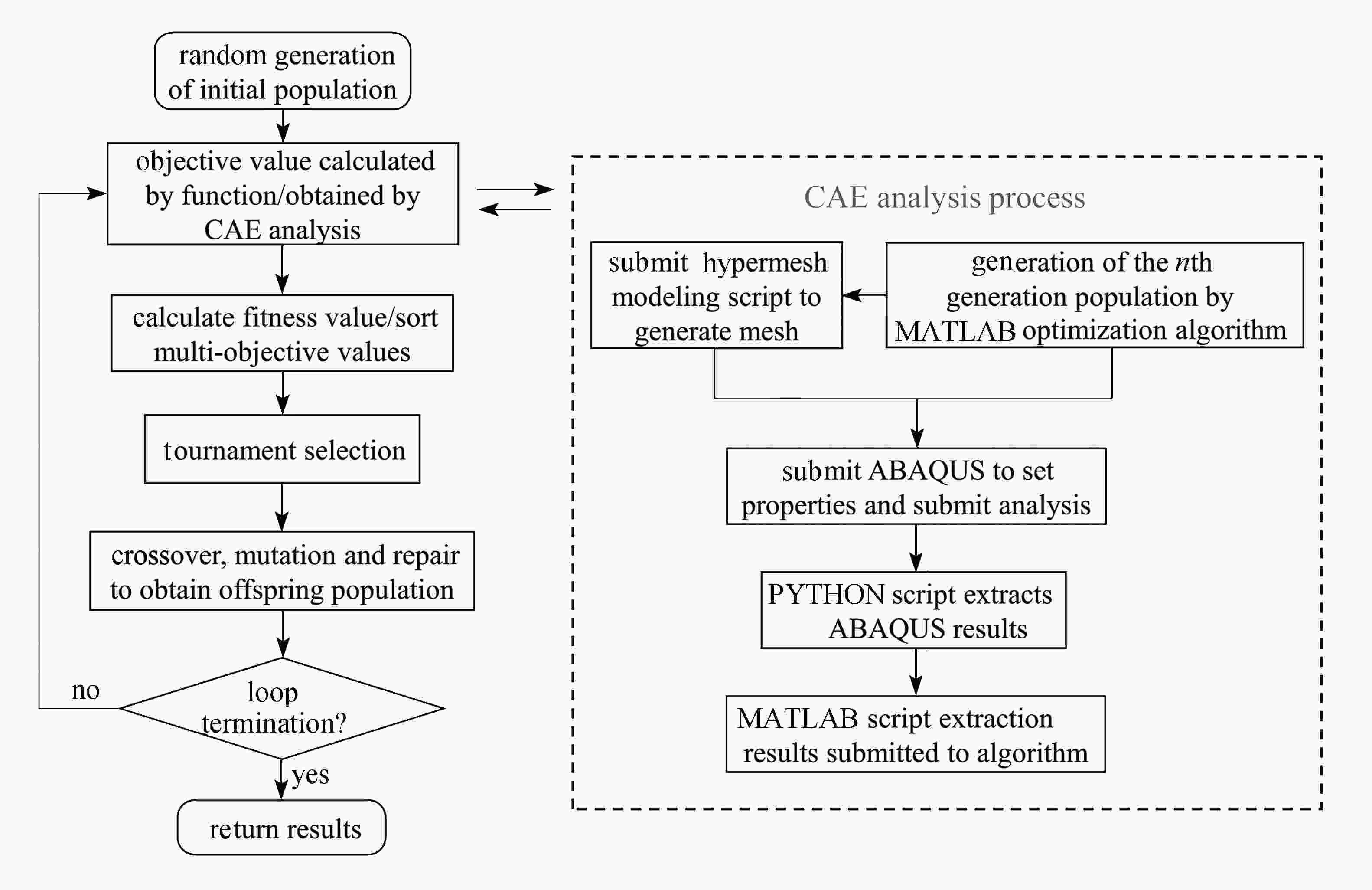

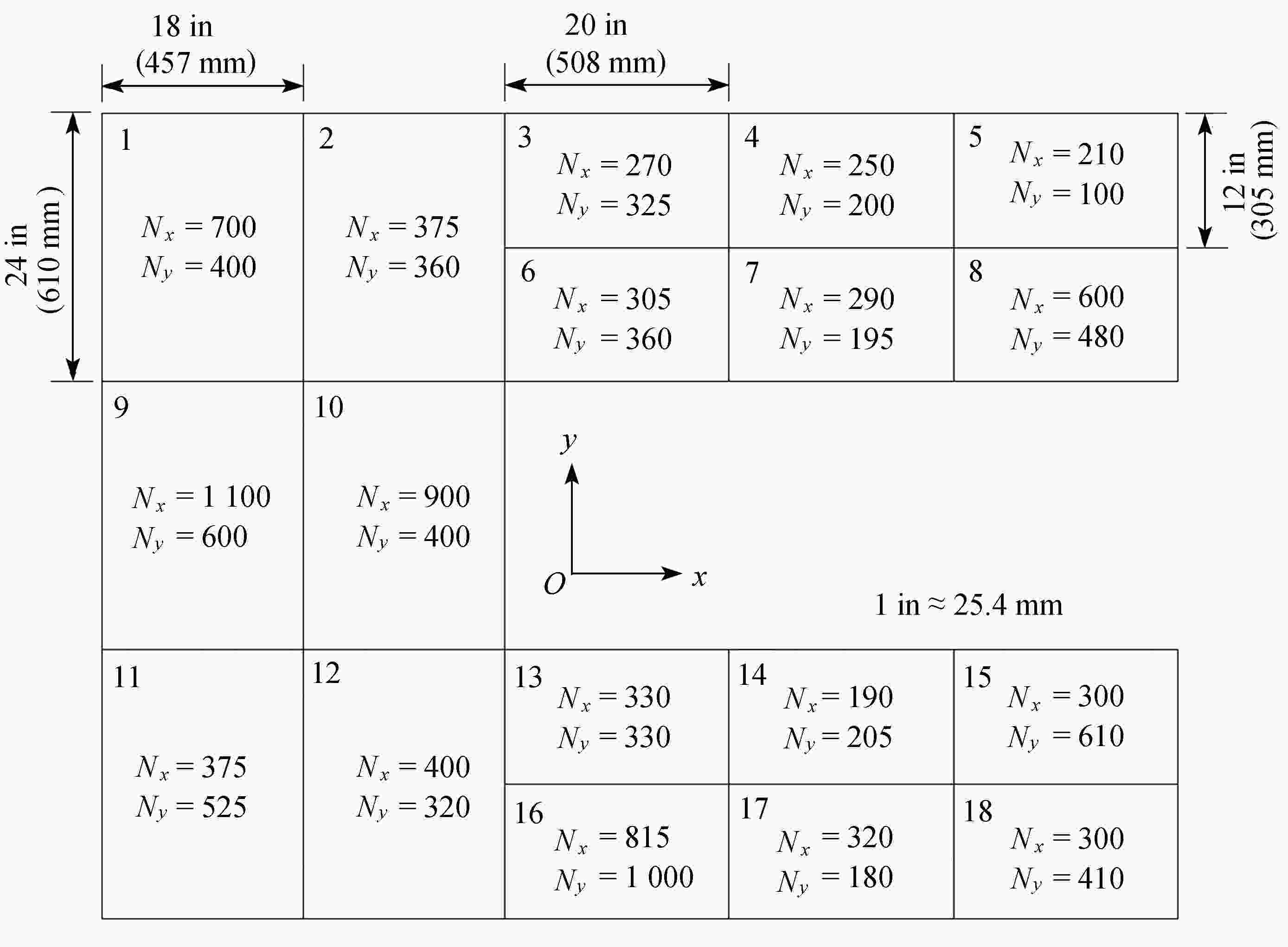

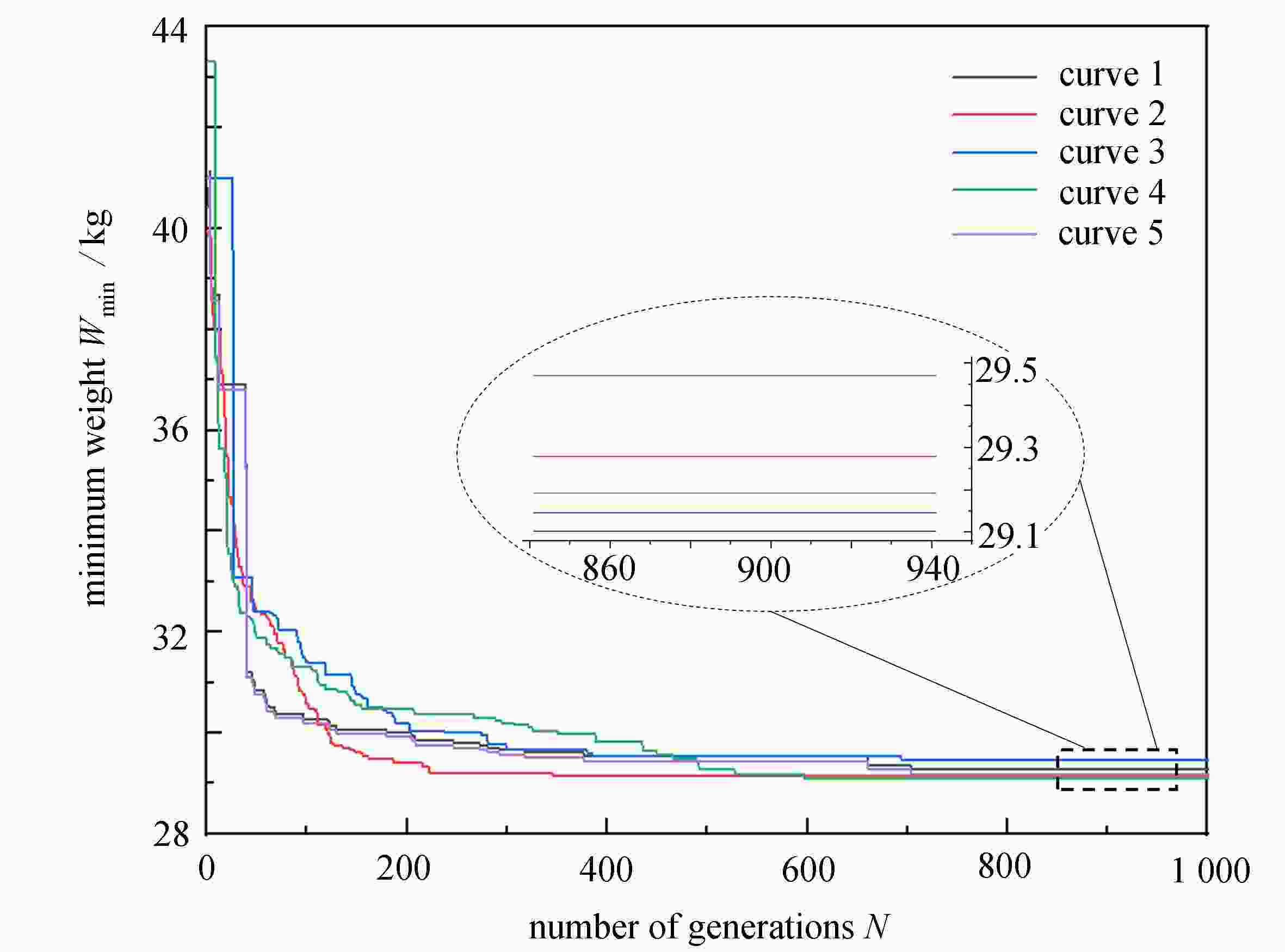

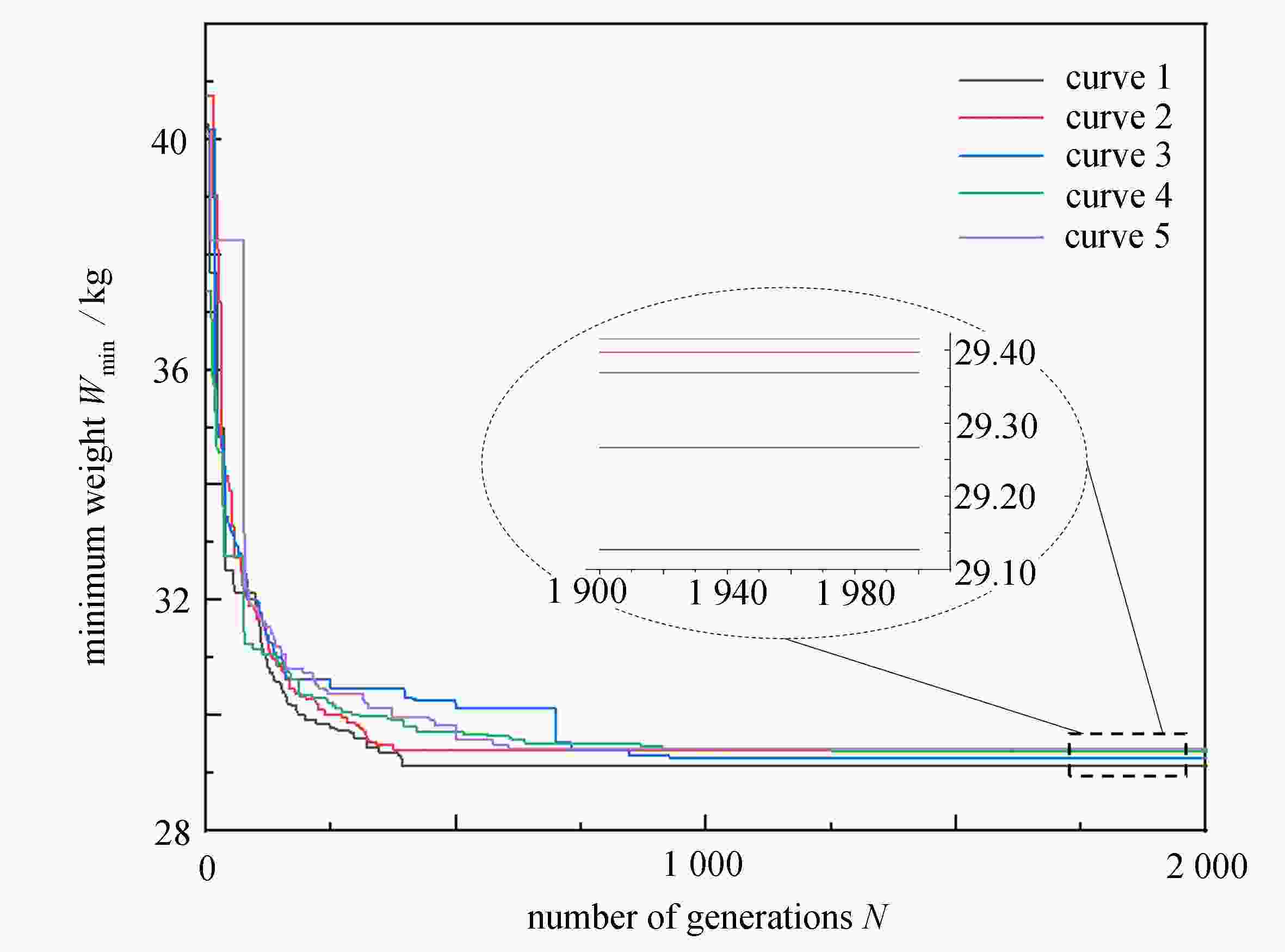

Abstract:Due to the high specific strength and stiffness, the use of continuous fiber reinforced composites instead of traditional metal materials to achieve structural lightweight has been widely considered by designers. However, the structural complexity brings great challenges to the design and optimization of composite lamination. Aimed at the problem of multiple constraints in the design of aviation composite laminates, the ply information of the structure was accurately expressed with gradually constructed design variables. Based on the classical genetic algorithm framework and the characteristics of all design variables, the genetic operators in the lamination optimization algorithm were defined, and the repair strategy was introduced to ensure that each generation of solutions could satisfy the design constraints and be distributed in the feasible region. Finally, the elite reservation strategy was used to improve the local optimization ability of the algorithm, which can reduce the computation cost of the lamination design of complex composite structures. Through the resolution of the classical benchmark problem and the comparison with the existing optimization results, the global and local optimization ability of the proposed lamination optimization algorithm was verified. The work provides theoretical supports for the optimization of composite lamination design in engineering practice.

-

表 1 优化算法参数取值

Table 1. Optimization algorithm parameter values

parameter value populationsize S 100 number of generations G 1000, 2 000 probability of chiasma Pc/% 0.9 probability of mutation Pm/% 0.1 elite reserved individual I 2 number of competition selections c 2 表 2 四种可选铺层角度下最优解变量取值

Table 2. Variable value of the optimal solution under 4 alternative ply angles

variable variable value Nstr [35 29 23 19 17 23 19 25 39 36 31 29 23 19 26 32 19 23] final Nstr [34 29 21 19 16 22 19 25 39 36 31 29 22 19 26 32 19 23] Slam [−45° 0° −45° 90° 45° 90° −45° −45° 0° −45° −45° 90° 45° 0° 45° 0° 0° 45° 0° 0° 45° 90° 45° 0°] Sins [0 1 2 2 0 1 6 1 5 1 0 0 8 4 1 4 0 1 1 1 7 0 9 1 3 1 0 7 5 6 0 3] 表 3 与SST方法最优解的比较

Table 3. Comparison with the optimal solution of the SST method

panel this paper solution SST number of plies Nplie margin η/% number of plies Nplie margin η/% 1 34(0) 2.7 34 17.2 2 29(−1) 0.6 30 15.9 3 21(−1) 1.4 22 36.4 4 19( + 1) 9.6 18 13.3 5 16(−2) 10.3 18 59.3 6 22(0) 4.4 22 22.6 7 19( + 1) 6.2 18 9.8 8 25(−1) 2.8 26 31.9 9 39( + 1) 0.6 38 6.9 10 36(−2) 0.6 38 25.6 11 31( + 1) 5.7 30 10.0 12 29(−1) 0.1 30 27.1 13 22(0) 9.3 22 28.3 14 19( + 1) 16.3 18 20.2 15 26(0) 11.9 26 27.8 16 32( + 2) 3.2 30 6.8 17 19( + 1) 7.7 18 11.3 18 23( + 1) 8.0 22 11.2 number of total plies Ntotal 461 460 weight W/kg 28.829 1 28.85 表 4 12种可选铺层角度下最优解变量取值

Table 4. Variable values of the optimal solution under 12 alternative ply angles

variable variable value Nstr [34 29 21 19 16 22 19 25 40 36 31 31 22 19 27 32 19 23] final Nstr [34 29 21 19 16 22 19 25 39 36 31 29 22 19 26 31 19 23] Slam [90° −45° −30° 0° −30° 0° −45° −30° −60° −45° 90° 45° 30° 45° 60° 30° 60° 30° 45° 0° 30° 0° −30° 0°] Sins [0 9 1 3 1 1 0 1 0 7 1 6 0 2 0 8 1 7 6 0 1 5 0 1 2 3 5 0 4 1 4 1] 表 5 与SST方法最优解的比较

Table 5. Comparison with the optimal solution of the SST method

panel this paper solution SST number of plies Nplie margin η/% number of plies Nplie margin η/% 1 34(0) 5.8 34 17.2 2 29(− 1) 2.9 30 15.9 3 21(− 1) 1.4 22 36.4 4 19( + 1) 9.4 18 13.3 5 16(− 2) 8.6 18 59.3 6 22(0) 4.6 22 22.6 7 19( + 1) 6.0 18 9.8 8 25(− 1) 2.8 26 31.9 9 39( + 1) 4.6 38 6.9 10 36(− 2) 3.1 38 25.6 11 31( + 1) 10.5 30 10.0 12 29(− 1) 2.4 30 27.1 13 22(0) 9.5 22 28.3 14 19( + 1) 16.1 18 20.2 15 26(0) 11.7 26 27.8 16 31( + 1) 4.6 30 6.8 17 19( + 1) 7.5 18 11.3 18 23( + 1) 7.7 22 11.2 number of total plies Ntotal 460 460 weight W/kg 28.782 6 28.85 -

[1] 朱迪, 姚远, 彭雄奇. 碳纤维汽车底盘后纵臂CAE设计的优化算法[J]. 应用数学和力学, 2018, 39(8): 925-934ZHU Di, YAO Yuan, PENG Xiongqi. An optimization algorithm for CAE design of carbon fiber reinforced composite chassis longitudinal arms[J]. Applied Mathematics and Mechanics, 2018, 39(8): 925-934.(in Chinese) [2] ZEHNDER N, ERMANNI P. A methodology for the global optimization of laminated composite structures[J]. Composite Structures, 2006, 72(3): 311-320. doi: 10.1016/j.compstruct.2005.01.021 [3] KIM J S, KIM C G, HONG C S. Optimum design of composite structures with ply drop using genetic algorithm and expert system shell[J]. Composite Structures, 1999, 46(2): 171-187. doi: 10.1016/S0263-8223(99)00052-5 [4] KRISTINSDOTTIR B P, ZABINSKY Z B, et al. Optimal design of large composite panels with varying loads[J]. Composite Structures, 2001, 51(1): 93-102. doi: 10.1016/S0263-8223(00)00128-8 [5] SOREMEKUN G, GURDAL Z, KASSAPOGLOU C, et al. Stacking sequence blending of multiple composite laminates using genetic algorithms[J]. Composite Structures, 2002, 56(1): 53-62. doi: 10.1016/S0263-8223(01)00185-4 [6] LIU D, TOROPOV V V, QUERIN O M, et al. Bi-level optimization of blended composite panels[J]. Journal of Aircraft, 2011, 48(1): 107-18. doi: 10.2514/1.C000261 [7] YANG J, SONG B, ZHONG X, et al. Optimal design of blended composite laminate structures using ply drop sequence[J]. Composite Structures, 2016, 135: 30-37. doi: 10.1016/j.compstruct.2015.08.101 [8] IRISARRI F X, LASSEIGNE A, LEROY F H, et al. Optimal design of laminated composite structures with ply drops using stacking sequence tables[J]. Composite Structures, 2014, 107: 559-569. doi: 10.1016/j.compstruct.2013.08.030 [9] GHIASI H, PASINI D, LESSAED L. Optimum stacking sequence design of composite materials part Ⅰ: constant stiffness design[J]. Composite Structures, 2009, 90(1): 1-11. doi: 10.1016/j.compstruct.2009.01.006 [10] 张洁. 复合材料铺层设计准则的一些理解[J]. 科技创新导报, 2013(14): 57-58.ZHANG Jie. Some understandings of design guidelines for composite laminated layers[J]. Science and Technology Innovation Review, 2013(14): 57-58. (in Chinese) [11] FEDON N, WEAVER P M, PIRRERA A, et al. A repair algorithm for composite laminates to satisfy lay-up design guidelines[J]. Composite Structures, 2021, 259: 113448. doi: 10.1016/j.compstruct.2020.113448 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号