Topology Optimizations of Integrated Thermal Protection Systems in Multiple Reentry Load Cases

-

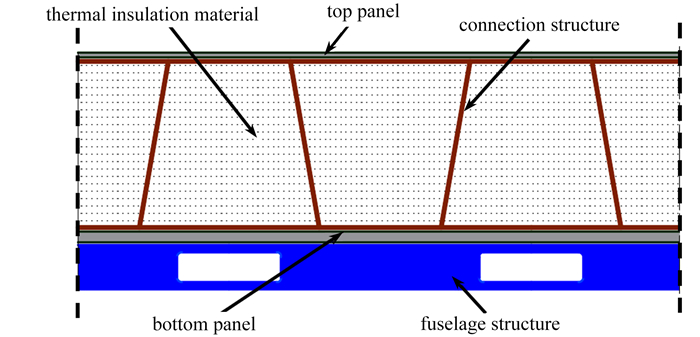

摘要: 一体化热防护系统(integrated thermal protection system, ITPS)需要同时满足承载与隔热的需求. 以波纹夹芯方案的ITPS为例,这需要其连接结构具有较高的力学性能与较低的热导率. 而再入环境的工况恶劣,如何合理地设计连接结构是ITPS性能提升的关键. 为解决这一问题,综合考虑了再入过程中气动热载荷最大时刻和气动压力载荷最大时刻对应的两种极端工况,以应变能和净传热速率的最小化作为目标函数,将质量作为约束条件,对ITPS的连接结构进行了拓扑优化. 随后对拓扑优化得到的构型重新建模并进行了热力耦合分析. 结果表明,拓扑优化得到的连接结构与文献中的初始波纹夹芯构型和单一工况下拓扑优化得到的构型相比,上面板的最大位移、下面板的温度和质量均有效降低. 由于材料用量的减少和结构复杂度的增加,连接结构在应力水平上有所增加,但仍满足使用需求. 这表明了考虑多再入工况的拓扑优化策略可以有效提升ITPS的刚度与隔热能力,缓解结构的热短路效应. 随着增材制造等相关技术的发展,拓扑优化在ITPS的连接结构以及其他的热结构设计中具有广阔的前景.Abstract: The integrated thermal protection system (ITPS) needs to meet both load-bearing and heat-insulating requirements. In terms of the ITPS with a corrugated sandwich structure, this requires the connection structure of the ITPS to have high mechanical properties with low thermal conductivity. However, the re-entry environment is severe, how to reasonably design the connection structure is key to improve the performances of the ITPS. To solve this problem, 2 extreme load conditions corresponding to the maximum aerodynamic heat load and the maximum aerodynamic pressure load during the reentry process were comprehensively considered, the objective function was constructed with the minimized strain energy and the net heat transfer rate, the mass was used as a constraint, and the topology optimization of the ITPS connection structure was carried out. Then, the configuration obtained through the topology optimization was reconstructed and the thermal mechanical coupling analysis was carried out. The results show that, the maximum displacement of the top panel, the temperature of the bottom panel and the mass of the optimized connection structure were reduced effectively compared with those of the initial corrugated sandwich configuration and the topology optimization configuration in single load cases in the literatures. Due to the reduction of material consumption and the increase of the structural complexity, the stress level of the connection structure increases, but it still meets the requirements of use. This means that, the topology optimization strategy considering multiple reentry load cases can effectively improve the stiffness and the insulation capacity of the ITPS and alleviate the thermal short-circuiting of the structure. With the development of additive manufacturing and other related technologies, the topology optimization method has broad prospects in the design of the connection structures for the ITPS and other thermal structures.

-

Key words:

- integrated thermal protection system /

- topology optimization /

- multiple load cases /

- thermo-mechanical coupling

edited-byedited-by1) (我刊编委唐光武来稿) -

表 1 ITPS的尺寸参数

Table 1. Sizes of the referenced ITPS design

parameter value parameter value tT/mm 2.1 h/mm 120.0 tW/mm 3.1 L/mm 117.0 tB/mm 5.3 θ/(°) 71.0 表 2 材料性能参数

Table 2. Material properties

material Inconel 718 TC4 Al 2024 Saffil density ρ/(kg/m3) 8 100 4 440 2 770 50 elastic modulus E/GPa 199(393 K)

153(1 033 K)115 71 - Poisson’s ratio μ 0.294 0.3 0.33 - thermal expansion coefficient α/K-1 1.26×10-5(373 K)

1.61×10-5(1 033 K)9.6×10-6 2.0×10-5 - thermal conductivity k/(W/(m·K)) 11.1(293 K)

28(1 273 K)7.6 816(255 K)

975(477 K)0.014(477 K)

0.154(1 144 K)specific heat c/(J/kg) 432(293 K)

620(1 070 K)560 944 942(389 K)

1 339(1 170 K)表 3 优化构型与参考构型的结构响应对比

Table 3. Comparison of structural responses between optimized configurations with reference configurations

ref #1 ref #2 opt #1 opt #2 DT, max/mm 5.16 2.97 1.90 1.87 TB, max/K 393.20 346.38 333.57 328.33 ST, max/MPa 579.61 289.36 327.80 312.99 SW, max/MPa 291.90 353.02 384.11 383.51 SB, max/MPa 199.30 52.43 99.67 88.38 Vf 0.045 2 0.045 1 0.032 0 0.029 0 -

[1] WEI K, HE R J, CHENG X M, et al. Fabrication and mechanical properties of lightweight ZrO2 ceramic corrugated core sandwich panels[J]. Materials & Design, 2014, 64: 91-95. [2] 郑辉, 邱雷, 袁慎芳, 等. C/C热防护结构高温气流损伤导波监测实验方法[J]. 航空学报, 2022, 43(8): 428-440. https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB202208031.htmZHENG Hui, QIU Lei, YUAN Shenfang, et al. Research on guided wave monitoring experimental method for high temperature airflow damage of C/C thermal protection structures[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(8): 428-440. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB202208031.htm [3] BAPANAPALLI S K, MARTINEZ O, GOGU C, et al. Analysis and design of corrugated-core sandwich panels for thermal protection system of space vehicles[C]// 47th AIAA Structures, Structural Dynamics and Materials Conference, Newport, American Institute of Aeronautics and Astronautics. Newport, Rhode Island, 2006. [4] WEI K, CHENG X M, MO F H, et al. Design and analysis of integrated thermal protection system based on lightweight C/SiC pyramidal lattice core sandwich panel[J]. Materials & Design, 2016, 111: 435-444. [5] LIANG H, WANG Y, TONG M, et al. Multi-scale strength analysis of bolted connections used in integral thermal protection system[J]. Chinese Journal of Aeronautics, 2018, 31(8): 1728-1740. doi: 10.1016/j.cja.2018.06.007 [6] 杨亚政, 杨嘉陵, 方岱宁. 高超声速飞行器热防护材料与结构的研究进展[J]. 应用数学和力学, 2008, 29(1): 47-56. http://www.applmathmech.cn/article/id/1021YANG Yazheng, YANG Jialing, FANG Daining. Research progress of thermal protection materials and structures for hypersonic vehicles[J]. Applied Mathematics and Mechanics, 2008, 29(1): 47-56. (in Chinese) http://www.applmathmech.cn/article/id/1021 [7] LE V T, HA N S, GOO N S. Advanced sandwich structures for thermal protection systems in hypersonic vehicles: a review[J]. Composites(Part B): Engineering, 2021, 226: 109301. doi: 10.1016/j.compositesb.2021.109301 [8] YANG Q, GAO B, XU Z Y, et al. Topology optimisations for integrated thermal protection systems considering thermo-mechanical constraints[J]. Applied Thermal Engineering, 2019, 150: 995-1001. doi: 10.1016/j.applthermaleng.2019.01.067 [9] 彭世彬, 郭瑞, 冯上升, 等. 主动冷却点阵夹层防热结构温度响应计算模型[J]. 应用数学和力学, 2022, 43(5): 477-489. doi: 10.21656/1000-0887.420405PENG Shibin, GUO Rui, FENG Shangsheng, et al. A calculation model for temperature responses of active cooling lattice sandwich structures for thermal protection[J]. Applied Mathematics and Mechanics, 2022, 43(5): 477-489. (in Chinese) doi: 10.21656/1000-0887.420405 [10] 王琪, 吉庭武, 谢公南, 等. 轻质热防护系统波纹夹芯结构热力耦合分析[J]. 应用数学和力学, 2013, 34(2): 172-182. doi: 10.3879/j.issn.1000-0887.2013.02.007WANG Qi, JI Tingwu, XIE Gongnan, et al. Thermal-mechanical coupling analysis of corrugated sandwich structure of lightweight thermal protection system[J]. Applied Mathematics and Mechanics, 2013, 34(2): 172-182. (in Chinese) doi: 10.3879/j.issn.1000-0887.2013.02.007 [11] CHEN Y, ZHANG L, HE C, et al. Thermal insulation performance and heat transfer mechanism of C/SiC corrugated lattice core sandwich panel[J]. Aerospace Science and Technology, 2021, 111: 106539. doi: 10.1016/j.ast.2021.106539 [12] SHI S B, DAI C X, WANG Y F. Design and optimization of an integrated thermal protection system for space vehicles[C]// 20th AIAA International Space Planes and Hypersonic Systems and Technologies Conference, Glasgow, American Institute of Aeronautics and Astronautics. Glasgow, Scotland, 2015: 3553. [13] XIE G, WANG Q, SUNDEN B, et al. Thermomechanical optimization of lightweight thermal protection system under aerodynamic heating[J]. Applied Thermal Engineering, 2013, 59(1/2): 425-434. [14] YANG Q, MENG S H, XIE W H, et al. Effective mitigation of the thermal short and expansion mismatch effects of an integrated thermal protection system through topology optimization[J]. Composites(Part B): Engineering, 2017, 118: 149-157. doi: 10.1016/j.compositesb.2017.03.038 [15] JIANG F, YE Z, YU W, et al. Analysis of reusable integrated thermal protection panel elements with various insulating core options[C]// 55th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Maryland, American Institute of Aeronautics and Astronautics. National Harbor, Maryland, 2014: 0351. [16] DEATON J D, GRANDHI R V. Stiffening of restrained thermal structures via topology optimization[J]. Structural and Multidisciplinary Optimization, 2013, 48(4): 731-745. doi: 10.1007/s00158-013-0934-5 [17] DEATON J D, GRANDHI R V. Stress-based design of thermal structures via topology optimization[J]. Structural and Multidisciplinary Optimization, 2016, 53(2): 253-270. [18] TAKEZAWA A, YOON G H, JEONG S H, et al. Structural topology optimization with strength and heat conduction constraints[J]. Computer Methods in Applied Mechanics & Engineering, 2014, 276: 341-361. [19] ZHANG W, YANG J, XU Y, et al. Topology optimization of thermoelastic structures: mean compliance minimization or elastic strain energy minimization[J]. Structural and Multidisciplinary Optimization, 2014, 49(3): 417-429. [20] WANG B, YAN J, CHENG G. Optimal structure design with low thermal directional expansion and high stiffness[J]. Engineering Optimization, 2011, 43(6): 581-595. [21] YANG Z H, ZHANG Y C, LIU S T, et al. Microstructural topology optimization for patch-based sandwich panel with desired in-plane thermal expansion and structural stiffness[J]. Structural and Multidisciplinary Optimization, 2021, 64(2): 779-795. [22] KIM W, GRANDHI R V, HANEY M. An evolutionary optimization method for designing a thermal protection system for dynamics[J]. Mechanics Based Design of Structures and Machines, 2006, 34(1): 1-24. [23] KIM W, GRANDHI R V, HANEY M. Multi-objective evolutionary optimization method for thermal protection system design[C]// 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics & Materials Conference, Austin, American Institute of Aeronautics and Astronautics. Austin, Texas, 2005: 2311. [24] PENMETSA R C, GRANDHI R V, HANEY M. Topology optimization for an evolutionary design of a thermal protection system[J]. AIAA Journal, 2012, 44(11): 2663-2671. [25] XU Q, LI S, MENG Y. Optimization and re-design of integrated thermal protection systems considering thermo-mechanical performance[J]. Applied Sciences, 2021, 11(15): 6916. [26] 杨强. 一体化热防护系统设计与综合效能评估方法研究[D]. 硕士学位论文. 哈尔滨: 哈尔滨工业大学, 2013.YANG Qiang. Design and performance evaluation method of integrated thermal protection systems[D]. Master Thesis. Harbin: Harbin Institute of Technology, 2013. (in Chinese) [27] 杜鹏. 大型箱体结构拓扑优化设计研究[D]. 硕士学位论文. 郑州: 郑州大学, 2016.DU Peng. A research on topology optimization design of large-scale box structure[D]. Master Thesis. Zhengzhou: Zhengzhou University, 2016. (in Chinese) [28] 叶红玲, 隋允康. 基于ICM方法三维连续体结构拓扑优化[J]. 固体力学学报, 2006, 27(4): 387-393. https://www.cnki.com.cn/Article/CJFDTOTAL-GTLX200604010.htmYE Hongling, SUI Yunkang. ICM based topological optimization of 3D continuum structure[J]. Chinese Journal of Solid Mechanics, 2006, 27(4): 387-393. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GTLX200604010.htm [29] 方子帆, 杨磊, 杜道佳, 等. 支撑结构多目标拓扑优化设计研究[J]. 中国机械工程, 2010, 21(15): 1836-1839. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGJX201015018.htmFANG Zifan, YANG Lei, DU Daojia, et al. Research on topology optimization design for support structure[J]. Chinese Mechanical Engineering, 2010, 21(15): 1836-1839. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGJX201015018.htm [30] BENDSØE M P, SIGMUND O. Material interpolation schemes in topology optimization[J]. Archive of Applied Mechanics, 1999, 69(9/10): 635-654. [31] MYERS D E, MARTIN C J, BLOSSER M L. Parametric weight comparison of current and proposed thermal protection system (TPS) concepts[C]// 33rd Thermophysics Conference, Norfolk, American Institute of Aeronautics and Astronautics. Norfolk, VA, 1999. [32] KRYSKO A V, AWREJCEWICZ J, PAVLOV S P, et al. Topological optimization of thermoelastic composites with maximized stiffness and heat transfer[J]. Composites(Part B): Engineering, 2019, 158: 319-327. [33] SVANBERG K. A class of globally convergent optimization methods based on conservative convex separable approximations[J]. SIAM Journal on Optimization, 2002, 12(2): 555-573. [34] 钛及钛合金棒材: GB/T 2965—2007[S]. 北京: 中国标准出版社, 2007.Titanium and titanium alloy bars: GB/T 2965—2007[S]. Beijing: Standards Press of China, 2007. (in Chinese) -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号