Effects of Impact Positions on Dynamic Responses of Thin-Walled Cylindrical Shells Under Lateral Shock Loadings

-

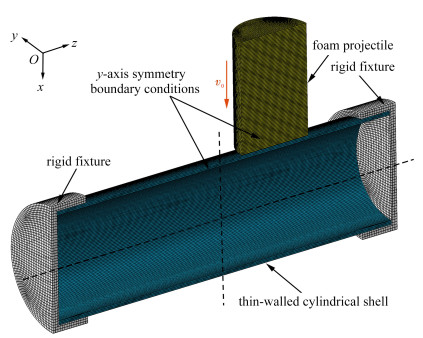

摘要: 采用有限元分析软件ABAQUS/Explicit研究泡沫子弹侧向冲击的冲击位置(偏置比)对Q235钢薄壁圆柱壳动态响应行为的影响. 基于已有的实验结果,验证了有限元模型的准确性,并通过该模型对比分析了不同偏置比下圆柱壳的动态变形演化、冲击侧与后侧冲击区域中心点的挠度值和圆柱壳的最终变形模式. 研究发现冲击侧冲击区域中心点的挠度均与冲击方向一致,而后侧冲击区域中心点的挠度均与冲击方向相反;圆柱壳的不对称变形模式随着偏置比的增大而更加明显. 进一步地,讨论了不同偏置比下,约束形式、初始动量及长径比对圆柱壳抗冲击能力的影响,结果表明,无论何种约束形式和初始动量大小,偏置比的增大降低了圆柱壳两侧冲击区域中心点挠度的绝对值,同时也减缓了后侧冲击区域中心点挠度在长径比影响下从凹陷到凸起的转变过程. 这种增强机制主要在于偏置比的增大显著提升了边界条件对圆柱壳的约束作用.Abstract: The effects of impact positions (offset ratios) on the dynamic behaviors of Q235 steel thin-walled cylindrical shells under lateral impacts by foam projectiles were explored with finite element software ABAQUS/Explicit. Based on existing experimental results, the accuracy of the finite element model was validated, and the model was employed to conduct a comparative analysis of the dynamic deformation evolution, the deflections at mid-points of the impact region on the impact and rear sides, and the final deformation modes of the cylindrical shell under different offset ratios. The results show that, the deflections at the mid-point of the impact region on the impact side are consistent with the impact direction, while those on the rear side are in the opposite direction; the asymmetric deformation mode of the cylindrical shell becomes more pronounced as the offset ratio increases. Subsequently, the effects of constraint types, initial momentums, and length-to-diameter ratios on the impact resistance of the cylindrical shell under offset lateral impact were studied. The comparisons indicate that, regardless of the constraint type or the initial momentum, an increase in the offset ratio will reduce the absolute values of the deflections at the mid-point of the impact region on both sides, which will also slow down the transition process of deflections at the mid-point of the impact region on the rear side from indentation to bulging, under the influence of the length-to-diameter ratio. This enhancement mechanism is primarily attributed to the significant improvement of the constraining effect of boundary conditions on the cylindrical shell as the offset ratio increases.

-

Key words:

- thin-walled cylindrical shell /

- lateral shock loading /

- foam projectile /

- offset ratio

-

表 1 Q235钢的J-C塑性模型参数

Table 1. The J-C plasticity model parameters of Q235

material ρ/(kg/m3) E/GPa νe A/MPa B/MPa n C $\dot{\varepsilon}_0$/s-1 Q235 7 800 200 0.3 293.8 230.2 0.578 0.065 2 0.002 1 -

[1] 沈志远. 含裂纹薄壁圆管的承载力学特性研究[D]. 武汉: 华中科技大学, 2022.SHEN Zhiyuan. Study on mechanical load-bearing characteristics of cracked thin-walled pipe[D]. Wuhan: Huazhong University of Science and Technology, 2022. (in Chinese) [2] 邹广平, 闫安石, 唱忠良, 等. 金属薄壁夹层结构变形形式及吸能特性研究[J]. 机械强度, 2023, 45(5): 1249-1253.ZOU Guangping, YAN Anshi, CHANG Zhongliang, et al. Study on deformation form and energy absorption characteristics of metal thin-walled sandwich structure[J]. Journal of Mechanical Strength, 2023, 45(5): 1249-1253. (in Chinese) [3] 洪金昌. 冲击载荷作用下圆柱壳支承结构的动态响应分析[D]. 哈尔滨: 哈尔滨工程大学, 2021.HONG Jinchang. Analysis on dynamic response of cylindrical shell supporting structure under impact load[D]. Harbin: Harbin Engineering University, 2021. (in Chinese) [4] POONAYA S, TEEBOONMA U, THINVONGPITUK C. Plastic collapse analysis of thin-walled circular tubes subjected to bending[J]. Thin-Walled Structures, 2009, 47(6/7): 637-645. [5] ZHANG R, ZHI X D, FAN F. Plastic behavior of circular steel tubes subjected to low-velocity transverse impact[J]. International Journal of Impact Engineering, 2018, 114: 1-19. doi: 10.1016/j.ijimpeng.2017.12.003 [6] SONG K, LONG Y, JI C, et al. Plastic deformation of metal tubes subjected to lateral blast loads[J]. Mathematical Problems in Engineering, 2014, 2014: 250379. doi: 10.1155/2014/250379 [7] 陈卫, 汤智宏, 彭林欣. 基于分层法的功能梯度三明治壳线性弯曲无网格分析[J]. 应用数学和力学, 2024, 45(5): 539-553. doi: 10.21656/1000-0887.440262CHEN Wei, TANG Zhihong, PENG Linxin. Linear bending analysis of functionally graded sandwich shells with the meshless method based on the layer-wise theory[J]. Applied Mathematics and Mechanics, 2024, 45(5): 539-553. (in Chinese) doi: 10.21656/1000-0887.440262 [8] WEIHS D, RITTEL D. Off-center high velocity impact on cylindrical pipes and shells[J]. Journal of Dynamic Behavior of Materials, 2021, 7(4): 526-537. doi: 10.1007/s40870-021-00299-3 [9] MOHAMMAD Z, GUPTA P K, BAQI A, et al. Energy dissipation characteristics of single curvature metallic shells subjected to ballistic impact[J]. European Journal of Mechanics A: Solids, 2021, 89: 104279. doi: 10.1016/j.euromechsol.2021.104279 [10] PARLOC 92. The update of loss of containment data for offshore pipelines: OTH-93-424[R]. 1994. [11] KHALILI S M R, SOROUSH M, DAVAR A, et al. Finite element modeling of low-velocity impact on laminated composite plates and cylindrical shells[J]. Composite Structures, 2011, 93(5): 1363-1375. doi: 10.1016/j.compstruct.2010.10.003 [12] CHEN K, SHEN W Q. Further experimental study on the failure of fully clamped steel pipes[J]. International Journal of Impact Engineering, 1998, 21(3): 177-202. doi: 10.1016/S0734-743X(97)00083-3 [13] KARAMANOS S A, ANDREADAKIS K P. Denting of internally pressurized tubes under lateral loads[J]. International Journal of Mechanical Sciences, 2006, 48(10): 1080-1094. doi: 10.1016/j.ijmecsci.2006.03.018 [14] LU G Y, ZHANG S Y, LEI J P, et al. Dynamic responses and damages of water-filled pre-pressurized metal tube impacted by mass[J]. International Journal of Impact Engineering, 2007, 34(10): 1594-1601. doi: 10.1016/j.ijimpeng.2006.07.006 [15] YU J X, ZHAO Y Y, LI T Y, et al. A three-dimensional numerical method to study pipeline deformations due to transverse impacts from dropped anchors[J]. Thin-Walled Structures, 2016, 103: 22-32. doi: 10.1016/j.tws.2016.02.006 [16] BROOKER D C. Denting of pressurised pipelines under localised radial loading[J]. International Journal of Mechanical Sciences, 2004, 46(12): 1783-1805. doi: 10.1016/j.ijmecsci.2004.11.004 [17] JONES N, BIRCH S E, BIRCH R S, et al. An experimental study on the lateral impact of fully clamped mild steel pipes[J]. Proceedings of the Institution of Mechanical Engineers (Part E): Journal of Process Mechanical Engineering, 1992, 206(2): 111-127. doi: 10.1243/PIME_PROC_1992_206_207_02 [18] WATSON A R, REID S R, JOHNSON W, et al. Large deformations of thin-walled circular tubes under transverse loading, Ⅱ: experimental study of the crushing of circular tubes by centrally applied opposed wedge-shaped indenters[J]. International Journal of Mechanical Sciences, 1976, 18(7/8): 387-397. [19] WATSON A R, REID S R, JOHNSON W. Large deformations of thin-walled circular tubes under transverse loading, Ⅲ: further experiments on the bending of simply supported tubes[J]. International Journal of Mechanical Sciences, 1976, 18(9/10): 501-502. [20] CHRISTOFOROU A P, SWANSON S R. Analysis of simply-supported orthotropic cylindrical shells subject to lateral impact loads[J]. Journal of Applied Mechanics, 1990, 57(2): 376. doi: 10.1115/1.2892000 [21] CORBETT G G, REID S R, JOHNSON W. Impact loading of plates and shells by free-flying projectiles: a review[J]. International Journal of Impact Engineering, 1996, 18(2): 141-230. doi: 10.1016/0734-743X(95)00023-4 [22] LI S, YU B, KARAGIOZOVA D, et al. Experimental, numerical, and theoretical studies of the response of short cylindrical stainless steel tubes under lateral air blast loading[J]. International Journal of Impact Engineering, 2019, 124: 48-60. doi: 10.1016/j.ijimpeng.2018.10.004 [23] WU J, JI C, LONG Y, et al. Dynamic responses and damage of cylindrical shells under the combined effects of fragments and shock waves[J]. Thin-Walled Structures, 2017, 113: 94-103. doi: 10.1016/j.tws.2017.01.009 [24] ZHU L, LIU Q, JONES N, et al. Experimental study on the deformation of fully clamped pipes under lateral impact[J]. International Journal of Impact Engineering, 2018, 111: 94-105. doi: 10.1016/j.ijimpeng.2017.09.008 [25] RADFORD D D, DESHPANDE V S, FLECK N A. The use of metal foam projectiles to simulate shock loading on a structure[J]. International Journal of Impact Engineering, 2005, 31(9): 1152-1171. doi: 10.1016/j.ijimpeng.2004.07.012 [26] YUE Z, WANG X, HE C, et al. Elevated shock resistance of all-metallic sandwich beams with honeycomb-supported corrugated cores[J]. Composites Part B: Engineering, 2022, 242: 110102. doi: 10.1016/j.compositesb.2022.110102 [27] JOHNSON G R, COOK W H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures[J]. Engineering Fracture Mechanics, 1983, 21: 541-548. [28] 郭子涛, 高斌, 郭钊, 等. 基于J-C模型的Q235钢的动态本构关系[J]. 爆炸与冲击, 2018, 38(4): 804-810.GUO Zitao, GAO Bin, GUO Zhao, et al. Dynamic constitutive relation based on J-C model of Q235 steel[J]. Explosion and Shock Waves, 2018, 38(4): 804-810. (in Chinese) [29] FAN Z S, GE S H, YUE Z S, et al. Dynamic response of clamped metallic thin-walled cylindrical shells under lateral shock loading[J]. Thin-Walled Structures, 2024, 200: 111922. doi: 10.1016/j.tws.2024.111922 [30] 张荣. 建筑用圆钢管构件侧向冲击响应及失效机理[D]. 哈尔滨: 哈尔滨工业大学, 2018.ZHANG Rong. Dynamic response and failure mechanism of structural tubular steel members subjected to transverse impact[D]. Harbin: Harbin Institute of Technology, 2018. (in Chinese) [31] REID S R, WANG B, HUA Y L. Triple plastic hinge mechanism for a bent cantilever beam subjected to an out-of-plane tip force pulse of finite duration[J]. International Journal of Impact Engineering, 1995, 16(1): 75-93. doi: 10.1016/0734-743X(94)00034-T [32] JONES N. Structural Impact[M]. Cambridge, UK: Cambridge University Press, 2011. [33] JONES N. The influence of large deflections on the behavior of rigid-plastic cylindrical shells loaded impulsively[J]. Journal of Applied Mechanics, 1970, 37(2): 416-425. doi: 10.1115/1.340852211922 [34] TIMOSHENKO S P, GERE J M. Theory of Elastic Stability[M]. 2nd ed. Mineola, NY: Dover Publications, 2009. [35] ZEINODDINI M, PARKE G A R, HARDING J E. Axially pre-loaded steel tubes subjected to lateral impacts: an experimental study[J]. International Journal of Impact Engineering, 2002, 27(6): 669-690. doi: 10.1016/S0734-743X(01)00157-9 [36] LU G X, YU T X. Energy Absorption of Structures and Materials[M]. Cambridge: Woodhead, 2003. -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号