Hydraulic Characterization and Impeller Optimization Design of Indoor Fire Pumps

-

摘要:

为了提高工程实际中的离心式消防泵性能,在原型泵的基础上,优化设计了一种高效、低振且扬程曲线平坦的高性能离心式消防泵. 针对消防泵目前存在的问题,基于计算流体力学方法,采用增加副叶片、改变副叶片长度的措施,设计和比较了3种优化方案. 结果表明:三种优化方案都在一定程度提高了消防泵性能. 优化方案2在设计点的扬程为42.6 m,效率为68.46%,消除了驼峰现象,降低了轴功率,并且提高了效率,综合考虑为最佳方案. 研究结果对工程实际中提升消防泵的性能、降低消防泵轴功率具有指导意义.

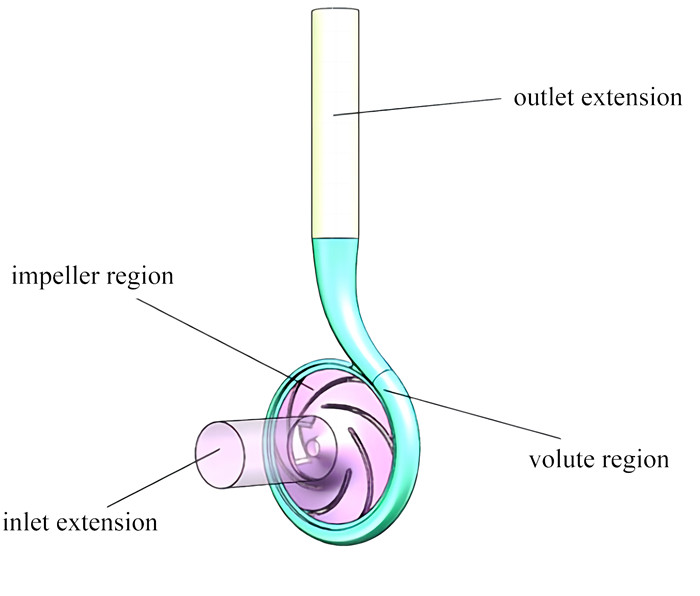

Abstract:To improve the performance of the engineering centrifugal fire pump, a high-performance centrifugal fire pump with high efficiency, low vibration and flat head curve was designed and optimized based on the prototype pump. Aimed at the existing problems of the fire pump, with the computational fluid dynamics method, 3 optimization plans were designed and compared through increase of the auxiliary blade and change of the auxiliary blade length. The results show that, all the 3 optimization plans can improve the fire pump performance to some extent. Optimization plan 2 has a lift of 42.6 m at the design point and an efficiency of 68.46%, eliminates the hump phenomenon, reduces the shaft power and improves the pump efficiency, which is synthetically chosen as the best plan. The research results have guiding significance for improving the fire pump performance and reducing the fire pump shaft power.

-

Key words:

- fire pump /

- optimized design /

- numerical simulation /

- internal flow characteristic /

- pressure pulsation

edited-byedited-by1) (我刊青年编委胡箫来稿) -

表 1 叶轮的主要几何参数

Table 1. The main geometric parameters of the impeller

geometric parameter symbol/unit value inlet diameter D1/mm 72 outlet diameter D2/mm 183 outlet width b2/mm 20.6 cornerite θ/(°) 86 number of blades Z 6 表 2 消防泵网格无关性验证

Table 2. The fire pump grid independence verification

plan number of grids in the impeller region efficiency/% plan 1 258 655 64.37 plan 2 315 427 63.42 plan 3 381 057 63.15 plan 4 459 103 62.64 plan 5 545 728 62.48 -

[1] 崔磊, 韩旭. 浅议高层火灾防范措施[J]. 科技视界, 2013(35): 382.CUI Lei, HAN Xu. On High-Rise Fire Prevention Measures[J]. Science & Technology Vision, 2013(35): 382. (in Chinese) [2] 芦鑫. 离心式消防泵水力优化及试验测量[D]. 镇江: 江苏大学, 2020.LU Xin. Hydraulic optimization and experimental measurement on centrifugal fire pumps[D]. Zhenjiang: Jiangsu University, 2020. (in Chinese) [3] 杨善明. 提高消防泵零流量压力的设计方法研究[J]. 机电工程技术, 2022, 51(4): 232-235.YANG Shanming. Research on design method of increasing zero flow pressure of fire pump[J]. Mechanical & Electrical Engineering Technology, 2022, 51(4): 232-235. (in Chinese) [4] 徐俊高. 基于仿真分析消防泵特性曲线计算[J]. 流体传动与控制, 2010(3): 37-39.XU Jungao. Simulation of characteristics curve of fire pump[J]. Fluid Power Transmission & Control, 2010(3): 37-39. (in Chinese) [5] 郭广强, 张人会, 赵万勇, 等. 浮潜式消防泵启动过程瞬态特性的数值模拟[J]. 排灌机械工程学报, 2019, 37(2): 118-123.GUO Guangqiang, ZHANG Renhui, ZHAO Wanyong, et al. Numerical simulation of transient characteristics of snorkeling fire pump during startup process[J]. Journal of Drainage and Irrigation Machinery Engineering, 2019, 37(2): 118-123. (in Chinese) [6] 王玥, 芦鑫, 王凯, 等. 离心式消防泵内流特性[J]. 排灌机械工程学报, 2022, 40(9): 865-873.WANG Yue, LU Xin, WANG Kai, et al. Internal flow characteristics of centrifugal fire pump[J]. Journal of Drainage and Irrigation Machinery Engineering, 2022, 40(9): 865-873. (in Chinese) [7] 刘宇宁. 叶片曲率半径变化对离心泵叶轮水力性能影响的研究[D]. 兰州: 兰州理工大学, 2020.LIU Yuning. Study on the influence of the variation of blade curvature radius on the hydraulic performance of centrifugal pump impeller[D]. Lanzhou: Lanzhou University of Technology, 2020. in Chinese [8] SHIM H S, KIM K Y. Effects of the number of blades on impeller-volute interaction and flow instability of a centrifugal pump[J]. Proceedings of the Institution of Mechanical Engineers (Part A): Journal of Power and Energy, 2022, 236(8): 1500-1517. doi: 10.1177/09576509221094951 [9] 唐卫卫. 离心水泵的优化设计及其仿真[D]. 咸阳: 西北农林科技大学, 2011.TANG Weiwei. Optimization design and numerical simulation of the centrifugal pump[D]. Xianyang: Northwest A&F University, 2011. in Chinese [10] 袁野. 车用消防离心泵内部流动机理及优化设计[D]. 镇江: 江苏大学, 2020.YUAN Ye. Inner flow mechanism and optimization design of a vehicle fire centrifugal pump[D]. Zhenjiang: Jiangsu University, 2020. (in Chinese) [11] 黄志辉, 邹晔, 魏昌洲, 等. 基于正交试验及CFD的消防泵叶轮优化设计[J]. 排灌机械工程学报, 2016, 34(12): 1040-1044.HUANG Zhihui, ZOU Ye, WEI Changzhou, et al. Optimization design based on orthogonal experiment and CFD on fire pump impeller[J]. Journal of Drainage and Irrigation Machinery Engineering, 2016, 34(12): 1040-1044. (in Chinese) [12] 张龙. 离心泵流场外特性及激励数值计算[J]. 防爆电机, 2021, 56(5): 20-22.ZHANG Long. Numerical calculation on flow field exterior characteristics and excitation of centrifugal pump[J]. Explosion-Proof Electric Machine, 2021, 56(5): 20-22. (in Chinese) [13] CHALGHOUM I, ELAOUD S, KANFOUDI H, et al. The effects of the rotor-stator interaction on unsteady pressure pulsation and radial force in a centrifugal pump[J]. Journal of Hydrodynamics, 2018, 30(4): 672-681. doi: 10.1007/s42241-018-0073-y [14] 陆伟刚, 董雷, 王兆飞, 等. 流量与环量对低扬程泵装置流道水头损失的交叉影响[J]. 应用数学和力学, 2012, 33(12): 1431-1441. doi: 10.3879/j.issn.1000-0887.2012.12.005 LU Weigang, DONG Lei, WANG Zhaofei, et al. Cross influence of discharge and circulation on head loss of the conduit of pump system with low head[J]. Applied Mathematics and Mechanics, 2012, 33(12): 1431-1441. (in Chinese) doi: 10.3879/j.issn.1000-0887.2012.12.005 [15] 张国涛, 尹延国. 变量叶片泵闭死容腔中压力变化特性及叶片受力分析[J]. 应用数学和力学, 2014, 35(4): 401-411. doi: 10.3879/j.issn.1000-0887.2014.04.006 ZHANG Guotao, YIN Yanguo. Pressure variation in sealed cavity and force analysis on vanes in variable displacement vane pumps[J]. Applied Mathematics and Mechanics, 2014, 35(4): 401-411. (in Chinese) doi: 10.3879/j.issn.1000-0887.2014.04.006 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号