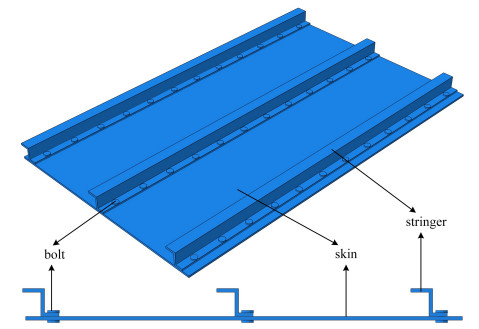

An Efficient Hybrid Structural Optimization Design Method for Bolt-Connected Stiffened Panels

-

摘要:

针对螺栓连接的加筋板屈曲性能优化建模复杂和计算量较大的问题,提出了一种基于Kriging代理模型和多点约束(multi-point constraint, MPC)近似模型的混合优化策略. 首先,运用MPC连接建立近似加筋板模型进行有限元屈曲分析,代替试验设计中大量的高精度加筋板模型分析. 然后,通过Kriging代理模型建立MPC参数的预测函数,并在优化迭代中更新代理模型样本点,保证近似模型的计算精度. 最后,基于建立的MPC近似模型,对螺栓连接加筋板进行了轻量化设计和性能最优化设计. 算例结果表明:该文提出的混合优化方法与传统优化方法相比,其计算效率提高了10倍左右. 在轻量化设计中,使加筋板结构在保证屈曲承载力不变的情况下减重了26.18%. 在性能最优化设计中,在质量无明显变化的情况下使极限屈曲承载力提高了23.67%.

Abstract:To address the modeling complexity and large computational load in optimizing the buckling performance of bolted stiffened panels, a hybrid optimization strategy based on the Kriging surrogate model and the multi-point constraint (MPC) approximation model was proposed. Firstly, the MPC connection was utilized to establish an approximate stiffened panel model for the finite element buckling analysis, to replace the analysis of many high-precision stiffened panel models in the experimental design. Then, a prediction function for MPC parameters was built with the Kriging surrogate model, and the sample points of the surrogate model were updated during optimization iterations to ensure the computational accuracy of the approximation model. Finally, based on the established MPC approximation model, the lightweight design and the performance optimization design of bolted stiffened panels were conducted. The numerical results demonstrate that, the proposed hybrid optimization method improves the computational efficiency by approximate 10 times compared with traditional optimization methods. In the lightweight design, the weight of the stiffened panel structure reduces by 26.18% while maintaining the same buckling capacity. In the performance optimization design, the ultimate buckling capacity increases by 23.67% without significant change in the structural mass.

-

Key words:

- stiffened panel /

- buckling analysis /

- surrogate model /

- structural optimization design

edited-byedited-by1) (我刊青年编委孟增来稿) -

表 1 设计变量上下边界

Table 1. Lower and upper bounds of design variables

L/mm H/mm D/mm h/mm d1/mm d2/mm d3/mm initial value 600 10 200 10 20 40 20 lower bound 200 0.5 100 0.5 10 10 10 upper bound 1 500 20 500 20 50 50 50 表 2 轻量化设计优化结果

Table 2. The optimization results of the lightweight design

initial design traditional method hybrid method L/mm 600 495.0 495.1 H/mm 10 9.8 9.5 D/mm 200 187.8 188.1 h/mm 10 15.9 15.5 d1/mm 20 22.6 22.7 d2/mm 40 45.1 45.1 d3/mm 20 10.4 10.8 W/kg 4.67 3.45 3.45 PMPC/MPa 155.41 - 153.64 Pbolt/MPa 156.74 155.45 155.21 δRE/% 0.85 - 1.02 iterative step - 80 81 CPU time/s - 64 980 8 676 表 3 屈曲性能最大化设计优化结果

Table 3. The optimization results of the maximum buckling performance design

initial design traditional method hybrid method L/mm 600 580.4 585.1 H/mm 10 11.5 11.1 D/mm 200 181.5 185.5 h/mm 10 13.2 14.8 d1/mm 20 22.1 23.7 d2/mm 40 12.5 13.8 d3/mm 20 25.1 25.1 W/kg 4.67 4.71 4.70 PMPC/MPa 155.41 - 193.85 Pbolt/MPa 156.74 194.17 195.82 δRE/% 0.85 - 1.01 iterative step - 46 46 CPU time/s - 37 310 4 909 -

[1] 飞机设计手册总编委会. 载荷、强度和刚度[M]. 飞机设计手册, 9册. 北京: 航空工业出版社, 2005.General Editorial Committee of the Aircraft Design Handbook. Load, Strength and Stiffness[M]. Aircraft Design Handbook, Vol 9. Beijing: Aviation Industry Press, 2005. (in Chinese) [2] 白瑞祥, 陈浩然. 含分层损伤复合材料加筋层合板的分层扩展研究[J]. 应用数学和力学, 2004, 25(4): 368-378. http://www.applmathmech.cn/article/id/54BAI Ruixiang, CHEN Haoran. Numerical analysis of delamination growth for stiffened composite laminated plates[J]. Applied Mathematics and Mechanics, 2004, 25(4): 368-378. (in Chinese) http://www.applmathmech.cn/article/id/54 [3] VENKATARAMAN S, HAFTKA R T. Optimization of composite panels: a review[C]//American Society for Composites, 1999: 479-488. [4] LANZI L, GIAVOTTO V. Post-buckling optimization of composite stiffened panels: computations and experiments[J]. Composite Structures, 2006, 73(2): 208-220. [5] 张涛, 刘土光, 熊有伦, 等. 流固冲击下加筋板的非线性动态屈曲[J]. 应用数学和力学, 2004, 25(7): 755-762. http://www.applmathmech.cn/article/id/369ZHANG Tao, LIU Tuguang, XIONG Youlun, et al. Dynamic buckling of stiffened plates under fluid-solid impact load[J]. Applied Mathematics and Mechanics, 2004, 25(7): 755-762. (in Chinese) http://www.applmathmech.cn/article/id/369 [6] NI X Y, PRUSTY B G, HELLIER A K. Buckling and post-buckling of isotropic and composite stiffened panels: a review on optimisation (2000-2015)[J]. International Journal of Maritime Engineering, 2016, 158(A3): A251-A267. [7] KIM D K, LIM H L, YU S Y. A technical review on ultimate strength prediction of stiffened panels in axial compression[J]. Ocean Engineering, 2018, 170: 392-406. [8] 王博, 郝鹏, 田阔. 加筋薄壳结构分析与优化设计研究进展[J]. 计算力学学报, 2019, 36(1): 1-12.WANG Bo, HAO Peng, TIAN Kuo. Recent advances in structural analysis and optimization of stiffened shells[J]. Chinese Journal of Computational Mechanics, 2019, 36(1): 1-12. (in Chinese) [9] 刘宸宇, 骆烜赫, 刘康翔, 等. 基于平铺刚度法的弧形加筋板的轻量化设计[J]. 应用数学和力学, 2023, 44(8): 953-964. doi: 10.21656/1000-0887.430342LIU Chenyu, LUO Xuanhe, LIU Kangxiang, et al. Lightweight design of arc rib stiffened plates based on the smeared stiffener method[J]. Applied Mathematics and Mechanics, 2023, 44(8): 953-964. (in Chinese) doi: 10.21656/1000-0887.430342 [10] HAO P, LIU D, LIU H, et al. Intelligent optimum design of large-scale gradual-stiffness stiffened panelsvia multi-level dimension reduction[J]. Computer Methods in Applied Mechanics and Engineering, 2024, 421: 116759. [11] 施利娟, 杨平. 高速船铝合金带筋板的力学性能优化设计[J]. 船海工程, 2011, 40(2): 36-39.SHI Lijuan, YANG Ping. Optimum design of mechanical properties of aluminum sheets-with-ribs of high speed ships[J]. Ship & Ocean Engineering, 2011, 40(2): 36-39. (in Chinese) [12] 郝鹏, 王博, 李刚, 等. 基于代理模型和等效刚度模型的加筋柱壳混合优化设计[J]. 计算力学学报, 2012, 29(4): 481-486.HAO Peng, WANG Bo, LI Gang, et al. Hybrid optimization of grid-stiffened cylinder based on surrogate model and smeared stiffener model[J]. Chinese Journal of Computational Mechanics, 2012, 29(4): 481-486. (in Chinese) [13] 张柱国, 姚卫星, 刘克龙. 基于进化Kriging模型的金属加筋板结构布局优化方法[J]. 南京航空航天大学学报, 2008, 40(4): 497-500.ZHANG Zhuguo, YAO Weixing, LIU Kelong. Configuration optimization method for metallic stiffened panel structure based on updated Kriging model[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2008, 40(4): 497-500. (in Chinese) [14] 时光辉, 贾宜播, 郝文宇, 等. 基于数据驱动的舵面结构优化设计[J]. 力学学报, 2023, 55(11): 2577-2587.SHI Guanghui, JIA Yibo, HAO Wenyu, WU Wenhua, LI Qiang, LIN Ye, DU Zongliang. Optimal design of rudder structures based on data-driven method[J]. Chinese Journal of Mechanical Mechanics, 2023, 55(11): 2577-2587. (in Chinese) [15] KAPANIA R, MULANI S, TAMIJANI A Y, et al. EBF3PanelOpt: a computational design environment for panels fabricated by additive manufacturing[C]// 51 st AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition. Texas, 2013: AIAA2013-212. [16] 赵振, 刘才山, 陈滨, 等. 薄壁加筋肋圆柱壳稳定性分析的参数化研究[J]. 力学与实践, 2004, 26(2): 17-21.ZHAO Zhen, LIU Caishan, CHEN Bin, et al. Parameterization study of orthogrid stiffened cylinder shells[J]. Mechanics and Engineering, 2004, 26(2): 17-21. (in Chinese) [17] TIAN K, WANG B, ZHANG K, et al. Tailoring the optimal load-carrying efficiency of hierarchical stiffened shells by competitive sampling[J]. Thin-Walled Structures, 2018, 133: 216-225. [18] 中国航空研究院. 复合材料连接手册[M]. 北京: 航空工业出版社, 1994.Chinese Aeronautical Establishment. Handbook of Joint for Composite Materials[M]. Beijing: Aviation Industry Press, 1994. (in Chinese) [19] MOU H, XIE J, FENG Z. Research status and future development of crashworthiness of civil aircraft fuselage structures: an overview[J]. Progress in Aerospace Sciences, 2020, 119: 100644. [20] MCCARTHY M A, MCCARTHY C T, LAWLOR V P, et al. Three-dimensional finite element analysis of single-bolt, single-lap composite bolted joints, part Ⅰ: model development and validation[J]. Composite Structures, 2005, 71(2): 140-158. [21] GRAY P J, MCCARTHY C T. A global bolted joint model for finite element analysis of load distributions in multi-bolt composite joints[J]. Composites (Part B): Engineering, 2010, 41(4): 317-325. [22] 刘建华. 轴向激励下螺栓连接结构的松动机理研究[D]. 成都: 西南交通大学, 2016.LIU Jianhua. Research on the self-loosening mechanism of bolted joints under axial excitation[D]. Chengdu: Southwest Jiaotong University, 2016. (in Chinese) [23] MATHAN G, PRASAD N S. Study of dynamic response of piping system with gasketed flanged joints using finite element analysis[J]. International Journal of Pressure Vessels and Piping, 2012, 89: 28-32. [24] AHMADIAN H, NOURMOHAMMADI M. Tool point dynamics prediction by a three-component model utilizing distributed joint interfaces[J]. International Journal of Machine Tools and Manufacture, 2010, 50(11): 998-1005. [25] 万春华, 段世慧, 吴存利. 加筋结构后屈曲有限元建模方法研究[J]. 机械科学与技术, 2015, 34(5): 795-798.WAN Chunhua, DUAN Shihui, WU Cunli. Study on the finite element modeling for post-buckling analysis of the stiffened structure[J]. Mechanical Science and Technology for Aerospace Engineering, 2015, 34(5): 795-798. (in Chinese) [26] 韩旭, 雷磊, 袁伟, 等. 基于等效模型的帽型复合材料加筋壁板优化设计[J]. 材料工程, 2009, 37(S2): 173-178.HAN Xu, LEI Lei, YUAN Wei, et al. Optimization of the composite hat-stiffened panel based on equivalent model[J]. Journal of Materials Engineering, 2009, 37(S2): 173-178. (in Chinese) [27] LV Z Y, LU Z Z, WANG P. A new learning function for Kriging and its applications to solve reliability problems in engineering[J]. Computers & Mathematics With Applications, 2015, 70(5): 1182-1197. -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号