Optimal Design of Battery Pack Heat Dissipation Topology Considering the Zonal Maximum Temperature Under Transient Effects

-

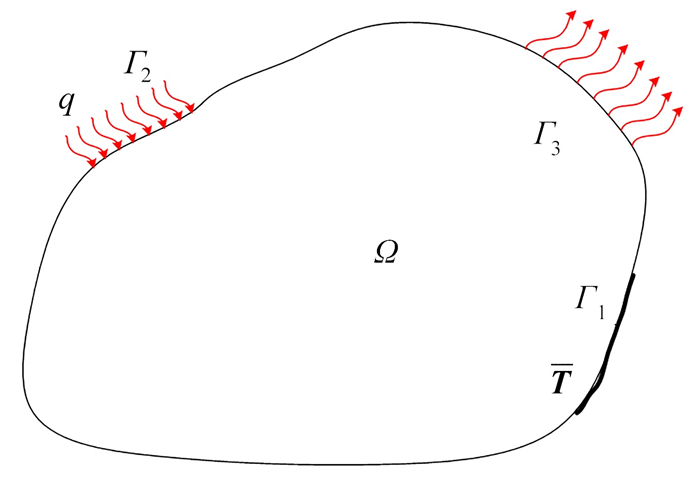

摘要: 电池包的散热程度是影响其稳定性、能效和续航里程等性能的关键因素,也是新能源汽车电池性能的瓶颈之一. 针对电池包的最高温度过大导致结构失效的问题,在考虑瞬态效应的影响的条件下,提出了一种能够表示结构特定区域最高温度的方法——区域温度控制函数,并把区域最高温度作为优化目标建立了对应的拓扑优化模型,从而实现了电池在工作时间、结构特定区域的最高温度的最小化设计. 通过伴随变量法推导了目标函数关于设计变量的敏度解析表达式,从而使设计的电池包结构更合理,满足电池包的热控制需求. 最后,通过具体电池散热片的优化、分析,表明该方法可以有效提高电池包的散热效率,降低特定区域的最高温度,减少温度不均匀性,在新能源汽车领域具有广阔的应用前景.Abstract: The heat dissipation degree of battery packs is a key factor affecting their stability, energy efficiency, and endurance, and is also one of the bottlenecks in the performances of new energy vehicle batteries. Aimed at the excessive maximum battery pack temperature and the consequent structure failure, and in view of the transient effects, a method representing the specific zonal maximum temperature of the structure, called the area temperature control function, was proposed. Meanwhile, a topology optimization model was established with the zonal maximum temperature as the optimization objective to minimize the zonal maximum temperature of the specific zone of the structure during working hours. Based on the adjoint variable method, the sensitivity analytical expression of the objective function based on design variables was derived. The optimization example results show that, the proposed method can effectively improve the heat dissipation efficiency, reduce the specific zonal maximum temperature and mitigate the temperature inhomogeneity, and has a broad application prospect in the field of new energy vehicles.

-

表 1 目标Ⅰ和目标Ⅱ不同工作时间下的最优构型

Table 1. Optimal configurations of target Ⅰ and target Ⅱ for different working hours

t/s target Ⅰ target Ⅱ t/s target Ⅰ target Ⅱ 50

1 000

100

5 000

250

10 000

500

20 000

表 2 结构在不同工作时间下的温度分布

Table 2. Temperature distributions for different operating hours

t/s target Ⅰ target Ⅱ 50

100

250

500

1 000

表 3 结构在不同充放电速率下的温度分布

Table 3. Temperature distributions for the structure at different charge-discharge rates

rate target Ⅰ target Ⅱ 0.5C

1C

2C

表 4 目标Ⅰ和目标Ⅱ不同体积分数下的最优构型

Table 4. Optimal configurations for different volume fractions of target Ⅰ and target Ⅱ

volume/% 25 35 45 55 60 target Ⅰ

target Ⅱ

表 5 结构在不同环境温度下的温度分布

Table 5. Temperature distributions of the structure for different ambient temperatures

T/℃ target Ⅰ target Ⅱ -20

25

40

-

[1] 齐创, 朱艳丽, 高飞, 等. 过充电条件下锂离子电池热失控数值模拟[J]. 北京理工大学学报, 2017, 37(10): 1048-1055.QI Chuang, ZHU Yanli, GAO Fei, et al. Thermal runaway analysis of lithium-ion battery with overcharge[J]. Transactions of Beijing Institute of Technology, 2017, 37(10): 1048-1055. (in Chinese) [2] FENG X, ZHENG S, REN D, et al. Investigating the thermal runaway mechanisms of lithium-ion batteries based on thermal analysis database[J]. Applied Energy, 2019, 246: 53-64. doi: 10.1016/j.apenergy.2019.04.009 [3] 邓通相, 匡格平, 胡兆财, 等. 多再入工况下一体化热防护系统拓扑优化设计[J]. 应用数学和力学, 2023, 44(11): 1299-1310. doi: 10.21656/1000-0887.440163DENG Tongxiang, KUANG Geping, HU Zhaocai, et al. Topology optimizations of integrated thermal protection systems in multiple reentry load cases[J]. Applied Mathematics and Mechanics, 2023, 44(11): 1299-1310. (in Chinese) doi: 10.21656/1000-0887.440163 [4] KUMAR T, SURESH K. A density-and-strain-based K-clustering approach to microstructural topology optimization[J]. Structural and Multidisciplinary Optimization, 2020, 61(4): 1399-1415. doi: 10.1007/s00158-019-02422-4 [5] RODRIGUES H, FERNANDES P. A material based model for topology optimization of thermoelastic structures[J]. International Journal for Numerical Methods in Engineering, 1995, 38(12): 1951-1965. doi: 10.1002/nme.1620381202 [6] SIGMUND O, TORQUATO S. Design of materials with extreme thermal expansion using a three-phase topology optimization method[J]. Journal of the Mechanics and Physics of Solids, 1997, 45(6): 1037-1067. doi: 10.1016/S0022-5096(96)00114-7 [7] DBOUK T. A review about the engineering design of optimal heat transfer systems using topology optimization[J]. Applied Thermal Engineering, 2017, 112: 841-854. doi: 10.1016/j.applthermaleng.2016.10.134 [8] MANUEL M C E, LIN P T. Design explorations of heat conductive pathways[J]. International Journal of Heat and Mass Transfer, 2017, 104: 835-851. doi: 10.1016/j.ijheatmasstransfer.2016.08.077 [9] LORENZINI G, BARRETO E X, BECKEL C C, et al. Geometrical evaluation of T-shaped high conductive pathway with thermal contact resistance for cooling of heat-generating medium[J]. International Journal of Heat and Mass Transfer, 2017, 108: 1884-1893. doi: 10.1016/j.ijheatmasstransfer.2017.01.008 [10] CHEN L, FENG H, XIE Z, et al. Thermal efficiency maximization for H- and X-shaped heat exchangers based on constructal theory[J]. Applied Thermal Engineering, 2015, 91: 456-462. doi: 10.1016/j.applthermaleng.2015.08.029 [11] LORENZINI G, BISERNI C, ROCHA L A O. Constructal design of X-shaped conductive pathways for cooling a heat-generating body[J]. International Journal of Heat and Mass Transfer, 2013, 58(1/2): 513-520. [12] FENG H, CHEN L, XIE Z, et al. Constructal design for "+" shaped high conductivity pathways over a square body[J]. International Journal of Heat and Mass Transfer, 2015, 91: 162-169. doi: 10.1016/j.ijheatmasstransfer.2015.07.105 [13] 丁一, 吴威涛, 封锋, 等. 三维点阵结构拓扑开发研究进展及其对流传热性能对比[J]. 应用数学和力学, 2024, 45(8): 1001-1023. doi: 10.21656/1000-0887.450184DING Yi, WU Weitao, FENG Feng, et al. Topology review and convective heat transfer comparison of 3D lattice structures[J]. Applied Mathematics and Mechanics, 2024, 45(8): 1001-1023. (in Chinese) doi: 10.21656/1000-0887.450184 [14] YAN S, WANG F, SIGMUND O. On the non-optimality of tree structures for heat conduction[J]. International Journal of Heat and Mass Transfer, 2018, 122: 660-680. doi: 10.1016/j.ijheatmasstransfer.2018.01.114 [15] IKONEN T J, MARCK G, SÓBESTER A, et al. Topology optimization of conductive heat transfer problems using parametric L-systems[J]. Structural and Multidisciplinary Optimization, 2018, 58(5): 1899-1916. doi: 10.1007/s00158-018-2055-7 [16] PARK J, NGUYEN T H, SHAH J J, et al. Conceptual design of efficient heat conductors using multi-material topology optimization[J]. Engineering Optimization, 2019, 51(5): 796-814. doi: 10.1080/0305215X.2018.1497613 [17] 王钦, 刘利阳, 强博, 等. 基于变密度胞元的热传导结构层级拓扑优化[J]. 应用数学和力学, 2023, 44(9): 1134-1144. doi: 10.21656/1000-0887.430383WANG Qin, LIU Liyang, QIANG Bo, et al. Topology optimization design of heat convection problems with variable-density cells[J]. Applied Mathematics and Mechanics, 2023, 44(9): 1134-1144. (in Chinese) doi: 10.21656/1000-0887.430383 [18] TANG L, GAO T, SONG L, et al. Topology optimization of nonlinear heat conduction problems involving large temperature gradient[J]. Computer Methods in Applied Mechanics and Engineering, 2019, 357: 112600. doi: 10.1016/j.cma.2019.112600 [19] ZHUANG C, XIONG Z. Temperature-constrained topology optimization of transient heat conduction problems[J]. Numerical Heat Transfer (Part B): Fundamentals, 2015, 68(4): 366-385. doi: 10.1080/10407790.2015.1033306 [20] LE C, NORATO J, BRUNS T, et al. Stress-based topology optimization for continua[J]. Structural and Multidisciplinary Optimization, 2010, 41(4): 605-620. doi: 10.1007/s00158-009-0440-y [21] SVANBERG K. The method of moving asymptotes: a new method for structural optimization[J]. International Journal for Numerical Methods in Engineering, 1987, 24(2): 359-373. doi: 10.1002/nme.1620240207 [22] 刘霏霏, 兰凤崇, 陈吉清. 基于动态内热源特性的车用锂离子动力电池温度场仿真及试验[J]. 机械工程学报, 2016, 52(8): 141-151.LIU Feifei, LAN Fengchong, CHEN Jiqing. Simulation and experiment on temperature field of lithium-ion power battery for vehicle based on characteristic of dynamic heat source[J]. Journal of Mechanical Engineering, 2016, 52(8): 141-151. (in Chinese) -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号