Study of Dynamic Loading Tests on Low-Impedance Specimens

-

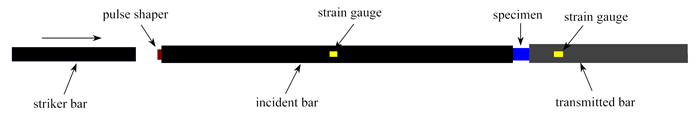

摘要: 研究了Hopkinson杆开展低阻抗试样高应变率加载测试的关键问题:低阻抗透射信号有效采集和应力平衡问题. 综合前期研究基础,选用异质低阻抗透射杆并辅以原位标定半导体应变片技术,实现低阻抗试样高精度测试;结合应力波加载试样的过程重构计算和分析,获得了低阻抗试样的应力平衡历程和影响因素敏感性特征,并提出了类梯形入射波,可使低阻抗试样尽早实现应力平衡和恒定应变率加载. 研究结果表明:低阻抗有机玻璃杆/管作为透射杆并辅以半导体应变片可实现载荷低至数Newton的透射信号采集;低阻抗试样应力平衡历程依赖于其弹性波速,在类梯形入射波加载下,2倍特征时间上升沿时可实现应力平衡以及其后的恒定应变率加载;其可基于试样厚度设计实现不同应变率加载下的临界有效应变一致性.Abstract: The key problems of the effective acquisition of low-impedance transmitted signals and the stress equilibrium in the Hopkinson bar loading tests on low-impedance specimens with high strain rates, were investigated. Based on the previous research fundaments, low-impedance elastic transmitted bars were introduced to replace the traditional metal transmitted bar, the in-situ calibrated semiconductor strain gauge technology was used to amplify weak transmitted signals, and the low-impedance specimens were tested with high precision. Reconstruction and calculation of the stress wave loading process were conducted to get the stress equilibrium history and the influential factors' sensitivity. The trapezoidal incident wave was proposed to realize stress equilibrium and achieve constant strain rate loading on specimens as early as possible. The results show that, low impedance polymethyl methacrylate bars/tubes as transmitted bars along with semiconductor strain gauges can acquire weak signals as low as several Newtons. The stress equilibrium history of the low-impedance specimen depends on the elastic wave velocity. Under the trapezoidal incident wave loading, the stress equilibrium and constant strain rate loading can be achieved at 2 characteristic periods. Based on the design of specimen thicknesses, the critical effective strain consistency can be achieved under different stress rate loadings.

-

Key words:

- Hopkinson bar /

- low-impedance specimen /

- dynamic loading /

- stress equilibrium /

- transmitted signal /

- high strain rate

-

表 1 金属栅丝应变片和半导体应变片输出电压信号对比

Table 1. Output signal comparison of the metal grid strain gauge and the semiconductor strain gauge

strain gauge input voltage /V resistance /Ω gain factor strain /με output signal /mV metal grid 30 1 000 150 100 2.74 semiconductor 30 1 000 2.10 100 213 表 2 改进型Hopkinson杆和试样尺寸与力学参数

Table 2. Dimensions and mechanic parameters of the modified SHPBs and specimens

incident bar(steel) specimen(rubber) specimen(TC4) transmitted bar(steel) transmitted bar(PMMA) diameter /mm 19 5 5 19 8 length or thickness /mm 3 100 5 5 3 100 1 000 elastic modulus /MPa 210 000 1 113 000 210 000 5 000 density /(kg/m3) 8 060 900 4 560 8 060 1 200 wave speed /(m/s) 5 104 33.33 4 978 5 104 2 041 specific impedance ratio 19 803 1 757 19 803 209 -

[1] 张龙辉, 张晓晴, 姚小虎, 等. 高应变率下航空透明聚氨酯的动态本构模型[J]. 爆炸与冲击, 2015, 35 (1): 51-56.ZHANG Longhui, ZHANG Xiaoqing, YAO Xiaohu, et al. Constitutive model of transparent aviation polyurethane at high strain rates[J]. Explosion and Shock Waves, 2015, 35 (1): 51-56. (in Chinese) [2] 许泽建, 丁晓燕, 张炜琪, 等. 一种用于材料高应变率剪切性能测试的新型加载技术[J]. 力学学报, 2016, 48 (3): 654-659.XU Zejian, DING Xiaoyan, ZHANG Weiqi, et al. A new loading technique for measuring shearing properties of materials under high strain rates[J]. Chinese Journal of Theoretical and Applied Mechanics, 2016, 48 (3): 654-659. (in Chinese) [3] 张方举, 何鹏, 胡文军, 等. 软材料的低阻抗SHPB实验技术与应用[J]. 中国测试, 2012, 38 (2): 17-20.ZHANG Fangju, HE Peng, HU Wenjun, et al. Application and experimental technique of low impedance SHPB for soft materials[J]. China Measurement & Test, 2012, 38 (2): 17-20. (in Chinese) [4] 章超, 徐松林, 王鹏飞. 基于数字图像相关方法对冲击载荷下泡沫铝全场变形过程的测试[J]. 实验力学, 2013, 28 (5): 629-634.ZHANG Chao, XU Songlin, WANG Pengfei. Test of aluminum foam deforming process under impact load based on digital image correlation method[J]. Journal of Experimental Mechanics, 2013, 28 (5): 629-634. (in Chinese) [5] HOU B, WANG Y, TANG Z B, et al. The mechanical behaviors of corrugated sandwich panel under quasi-static and dynamic shear-compressive loadings[J]. International Journal of Impact Engineering, 2021, 156 : 103956. doi: 10.1016/j.ijimpeng.2021.103956 [6] 周睿, 张志家, 张旺, 等. 多壁管增强泡沫铝结构动态响应及吸能性能研究[J]. 应用数学和力学, 2024, 45 (1): 12-24. doi: 10.21656/1000-0887.440186ZHOU Rui, ZHANG Zhijia, ZHANG Wang, et al. Dynamic response and energy absorption performances of multi-walled tube reinforced aluminum foam structure[J]. Applied Mathematics and Mechanics, 2024, 45 (1): 12-24. (in Chinese) doi: 10.21656/1000-0887.440186 [7] 范志庚, 万强, 牛红攀, 等. 计及时变演化特征的硅泡沫垫层非线性黏弹性模型研究[J]. 应用数学和力学, 2024, 45 (2): 167-174. doi: 10.21656/1000-0887.440249FAN Zhigeng, WAN Qiang, NIU Hongpan, et al. A nonlinear viscoelastic model for silicon rubber foam cushion considering time-varying evolution characteristics[J]. Applied Mathematics and Mechanics, 2024, 45 (2): 167-174. (in Chinese) doi: 10.21656/1000-0887.440249 [8] MIAO Y G, ZHANG H N, HE H, et al. Mechanical behaviors and equivalent configuration of a polyurea under wide strain rate range[J]. Composite Structures, 2019, 222 : 110923. doi: 10.1016/j.compstruct.2019.110923 [9] 高宁, 朱志武. 铝合金应变率效应综述及其机理研究[J]. 应用数学和力学, 2014, 35 (S1): 208-212.GAO Ning, ZHU Zhiwu. Study on the strain rate effects and mechanisms for aluminum alloys[J]. Applied Mathematics and Mechanics, 2014, 35 (S1): 208-212. (in Chinese) [10] CHEN C Y, ZHANG C, LIU C L, et al. Rate-dependent tensile failure behavior of short fiber reinforced PEEK[J]. Composites (Part B): Engineering, 2018, 136 : 187-196. doi: 10.1016/j.compositesb.2017.10.031 [11] QIN D Y, MIAO Y G, LI Y L. Formation of adiabatic shearing band for high-strength Ti-5553 alloy: a dramatic thermoplastic microstructural evolution[J]. Defence Technology, 2022, 18 (11): 2045-2051. doi: 10.1016/j.dt.2022.06.010 [12] MIAO Y G, DU W X, YIN J P, et al. Characterizing multi mechanical behaviors for epoxy-like materials under wide strain rate range[J]. Polymer Testing, 2022, 116 : 107804. doi: 10.1016/j.polymertesting.2022.107804 [13] WU Z B, YIN J P, LI M, et al. Rate-dependent constitutive behavior and mechanism of CMDB under tension loading[J]. Polymer Testing, 2024, 140 : 108584. doi: 10.1016/j.polymertesting.2024.108584 [14] HOPKINSON B. A method of measuring the pressure produced in the detonation of high explosives or by the impact of bullets[J]. Proceedings of the Royal Society of London (Series A), 1914, 89 (612): 411-413. [15] MIYAMBO M E, VON KALLON D V, PANDELANI T, et al. Review of the development of the split Hopkinson pressure bar[J]. Procedia CIRP, 2023, 119 : 800-808. doi: 10.1016/j.procir.2023.04.010 [16] WANG L L. Foundations of Stress Waves[M]. Amsterdam: Elsevier, 2007: 43-49, 65-70. [17] CHEN W, SONG B. Split Hopkinson (Kolsky) Bar Design, Testing and Applications[M]. New York: Springer, 2010: 37-51. [18] 卢芳云, 陈荣, 林玉亮, 等. 霍普金森杆实验技术[M]. 北京: 科学出版社, 2013: 23-52.LU Fangyun, CHEN Rong, LIN Yuliang, et al. Hopkinson Bar Techniques[M]. Beijing: Science Press, 2013: 23-52. (in Chinese) [19] 胡时胜. Hopkinson压杆实验技术的应用进展[J]. 实验力学, 2005, 20 (4): 589-594. doi: 10.3969/j.issn.1001-4888.2005.04.016HU Shisheng. The application development of experimental technique of Hopkinson pressure bar[J]. Journal of Experimental Mechanics, 2005, 20 (4): 589-594. (in Chinese) doi: 10.3969/j.issn.1001-4888.2005.04.016 [20] ZHAO H, GARY G, KLEPACZKO J R. On the use of a viscoelastic split Hopkinson pressure bar[J]. International Journal of Impact Engineering, 1997, 19 (4): 319-330. doi: 10.1016/S0734-743X(96)00038-3 [21] CHEN W, ZHANG B, FORRESTAL M J. A split Hopkinson bar technique for low-impedance materials[J]. Experimental Mechanics, 1999, 39 : 81-85. doi: 10.1007/BF02331109 [22] CHEN W, LU F, ZHOU B. A quartz-crystal-embedded split Hopkinson pressure bar for soft materials[J]. Experimental Mechanics, 2000, 40 (1): 1-6. doi: 10.1007/BF02327540 [23] SONG B, CHEN W, JIANG X. Split Hopkinson pressure bar experiments on polymeric foams[J]. International Journal of Vehicle Design, 2005, 37 (2/3): 185-198. doi: 10.1504/IJVD.2005.006656 [24] YIN J P, MIAO Y G, WU Z B, et al. A novel Hopkinson tension bar system for testing polymers under intermediate strain rate and large deformation[J]. International Journal of Impact Engineering, 2025, 198 : 105197. doi: 10.1016/j.ijimpeng.2024.105197 [25] 王宝珍, 郑宇轩, 胡时胜. 猪后腿肌肉的动态拉伸性能[J]. 爆炸与冲击, 2010, 30 (5): 449-455.WANG Baozhen, ZHENG Yuxuan, HU Shisheng. Dynamic tensile properties of porcine ham muscle[J]. Explosion and Shock Waves, 2010, 30 (5): 449-455. (in Chinese) [26] 徐沛保, 巫绪涛, 李和平. 中高应变率下EPS泡沫的冲击压缩实验[J]. 实验力学, 2012, 27 (4): 480-485.XU Peibao, WU Xutao, LI Heping. Impact compression experiment for EPS foam under mid-high strain rate[J]. Journal of Experimental Mechanics, 2012, 27 (4): 480-485. (in Chinese) [27] MIAO Y G, LI Y L, DENG Q, et al. Investigation on experimental method of low-impedance materials using modified Hopkinson pressure bar[J]. Journal of Beijing Institute of Technology, 2015, 24 (2): 269-276. [28] 周永康, 陈力, 崔世堂. 一种新型软材料动态直接拉伸实验技术[J]. 振动与冲击, 2017, 36 (22): 144-148.ZHOU Yongkang, CHEN Li, CUI Shitang. An improved SHTB experimental facility for soft material[J]. Journal of Vibration and Shock, 2017, 36 (22): 144-148. (in Chinese) [29] 鲍振宇, 温垚珂, 韩瑞国, 等. 弹道明胶的动态力学测试方法研究[J]. 中国测试, 2019, 45 (9): 33-37.BAO Zhenyu, WEN Yaoke, HAN Ruiguo, et al. Study on dynamic mechanical testing method of ballistic gelatin[J]. China Measurement & Test, 2019, 45 (9): 33-37. (in Chinese) [30] XU P D, TANG L Q, ZHANG Y R, et al. SHPB experimental method for ultra-soft materials in solution environment[J]. International Journal of Impact Engineering, 2022, 159 : 104051. doi: 10.1016/j.ijimpeng.2021.104051 [31] WEN Y K, XU L, CHEN A J, et al. Dynamic compressive response of porcine muscle measured using a split Hopkinson bar system with a pair of PVDF force transducers[J]. Defence Technology, 2023, 28 : 298-305. doi: 10.1016/j.dt.2022.08.011 [32] MIAO Y, GOU X, SHEIKH M Z. A technique for in situ calibration of semiconductor strain gauges used in Hopkinson bar tests[J]. Experimental Techniques, 2018, 42 : 623-629. doi: 10.1007/s40799-018-0283-9 [33] ZHANG J X, MIAO Y G, QIN Q H, et al. Static and dynamic experiments on hydrogels: effects of the chemical composition of the fluid[J]. Mechanics of Materials, 2021, 154 : 103717. doi: 10.1016/j.mechmat.2020.103717 [34] LIU Y, DENG Q, WANG Y S, et al. Dynamic mechanical response and functional mechanisms in rabbit pulmonary tissue[J]. Mechanics of Time-Dependent Materials, 2024, 28 (4): 2921-2936. doi: 10.1007/s11043-024-09697-1 [35] 周风华, 王礼立, 胡时胜. 高聚物SHPB试验中试件早期应力不均匀性的影响[J]. 实验力学, 1992, 7 (1): 23-29.ZHOU Fenghua, WANG Lili, HU Shisheng. On the effect of stress nonuniformness in polymer specimen of SHPB tests[J]. Journal of Experimental Mechanics, 1992, 7 (1): 23-29. (in Chinese) [36] RAVICHANDRAN G, SUBHASH G. Critical appraisal of limiting strain rates for compression testing of ceramics in a split Hopkinson pressure bar[J]. Journal of the American Ceramic Society, 1994, 77 (1): 263-267. doi: 10.1111/j.1151-2916.1994.tb06987.x [37] YANG L M, SHIM V P W. An analysis of stress uniformity in split Hopkinson bar test specimens[J]. International Journal of Impact Engineering, 2005, 31 (2): 129-150. doi: 10.1016/j.ijimpeng.2003.09.002 [38] 王礼立, 王永刚. 应力波在用SHPB研究材料动态本构特性中的重要作用[J]. 爆炸与冲击, 2005, 25 (1): 17-25.WANG Lili, WANG Yonggang. The important role of stress waves in the study on dynamic constitutive behavior of materials by SHPB[J]. Explosion and Shock Waves, 2005, 25 (1): 17-25. (in Chinese) [39] ZHU J, HU S, WANG L. An analysis of stress uniformity for concrete-like specimens during SHPB tests[J]. International Journal of Impact Engineering, 2009, 36 (1): 61-72. doi: 10.1016/j.ijimpeng.2008.04.007 [40] FREW D J, FORRESTAL M J, CHEN W. A split Hopkinson pressure bar technique to determine compressive stress-strain data for rock materials[J]. Experimental Mechanics, 2001, 41 (1): 40-46. doi: 10.1007/BF02323102 [41] 徐明利, 张若棋, 王悟, 等. 波形整形器在酚醛树脂的霍普金森压杆实验中的应用[J]. 爆炸与冲击, 2002, 22 (4): 377-380. doi: 10.3321/j.issn:1001-1455.2002.04.017XU Mingli, ZHANG Ruoqi, WANG Wu, et al. Application of wave shaper in SHPB experimental study of phenolic resin[J]. Explosion and Shock Waves, 2002, 22 (4): 377-380. (in Chinese) doi: 10.3321/j.issn:1001-1455.2002.04.017 [42] SONG B, CHEN W. Dynamic stress equilibration in split Hopkinson pressure bar tests on soft materials[J]. Experimental Mechanics, 2004, 44 (3): 300-312. doi: 10.1007/BF02427897 [43] MIAO Y G. On loading ceramic-like materials using split Hopkinson pressure bar[J]. Acta Mechanica, 2018, 229 (8): 3437-3452. doi: 10.1007/s00707-018-2166-7 [44] LIU L T, DENG Q, WANG R F, et al. Dynamic enhancement induced by interface for additively manufactured continuous carbon fiber reinforced composites[J]. Polymer Testing, 2024, 132 : 108382. doi: 10.1016/j.polymertesting.2024.108382 [45] YIN J P, ZHANG C X, SUN R H, et al. Controllable kilohertz impact fatigue loading functioned by cyclic stress wave of Hopkinson tension bar and its application for TC4 titanium alloy[J]. International Journal of Fatigue, 2025, 194 : 108828. doi: 10.1016/j.ijfatigue.2025.108828 [46] ZHANG C X, SUN R H, YIN J P, et al. Failure behaviours of steel/aluminium threaded connections under impact fatigue[J]. Engineering Failure Analysis, 2025, 174 : 109473. doi: 10.1016/j.engfailanal.2025.109473 [47] MIAO Y G, LI Y L, LIU H Y, et al. Determination of dynamic elastic modulus of polymeric materials using vertical split Hopkinson pressure bar[J]. International Journal of Mechanical Sciences, 2016, 108/109 : 188-196. doi: 10.1016/j.ijmecsci.2016.02.005 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号