Numerical Simulation of Stand-Off Distance Effects on Explosive Welding Quality of Titanium-Stainless Steel

-

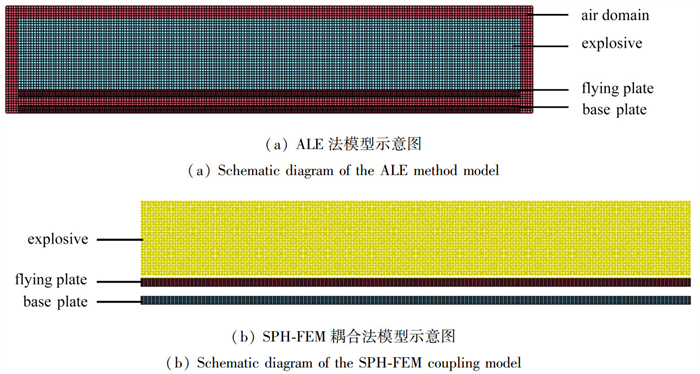

摘要: 研究了基复板间距对钛(TP 270C)与不锈钢(SUS 821L1)复合板爆炸焊接质量的影响. 使用ANSYS/LS-DYNA有限元软件,并结合两种不同算法(ALE法、SPH-FEM耦合法),对不同基复板间距(1.2 mm,2.2 mm,3.5 mm)下的爆炸焊接过程进行了三维数值模拟. 模拟结果显示,在ALE法和SPH-FEM耦合法两种算法下,三组模拟复板竖向位移均达到或超过基复板间距,碰撞速度与碰撞角度均位于焊接窗口有效区间内. 此外,随着间距增大,复板碰撞速度和碰撞角呈现正向增长趋势,其中间距为3.5 mm时,复合板表现出最佳焊接质量. 模拟验证了两种算法均适用于钛合金(TP 270C)与不锈钢(SUS 821L1)的爆炸焊接. 三种间距下钛合金(TP 270C)与不锈钢(SUS 821L1)可实现稳定复合,随着间距的增大,焊接界面的结合强度逐渐提高.

-

关键词:

- 间距 /

- 爆炸焊接 /

- ALE算法 /

- SPH-FEM耦合算法

Abstract: The effects of stand-off distance on explosive welding quality between titanium (TP 270C) and stainless steel (SUS 821L1) composite plates, were investigated. The 3D numerical simulations were conducted with the ANSYS/LS-DYNA software by 2 algorithms (the ALE method and the SPH-FEM coupling method) for 3 stand-off distances: 1.2 mm, 2.2 mm and 3.5 mm. The simulation results show that, for both algorithms the vertical displacements of flyer plates reach or exceed respective stand-off distances. The collision velocities and angles consistently fall within the acceptable range of the welding window. The collision velocity and angle exhibit positive correlations with increasing stand-off distances. Optimal welding quality occurs at the 3.5 mm stand-off distance. The results verify that both algorithms effectively simulate explosive welding between the TP 270C titanium alloy and the SUS 821L1 stainless steel. Stable bonding is achievable across all tested stand-off distances. Moreover, the interfacial bonding strength increases progressively with the stand-off distance, which demonstrates an enhancement mechanism in welding quality through parameter optimization.-

Key words:

- stand-off distance /

- explosive welding /

- ALE algorithm /

- SPH-FEM coupling algorithm

-

表 1 爆炸焊接几何参数

Table 1. Geometric parameters of explosive welding

material size/(mm×mm×mm) stand-off distance/mm TP 270C 200×100×3 SUS 821L1 200×100×3 1.2,2.2,3.5 ANFO-A 200×100×28 表 2 铵油炸药JWL状态方程参数

Table 2. The JWL model for ammonium oil explosives and its state equation parameters

parameter A/GPa B/GPa R1 R2 ω value 49.4 0.423 5.3 1.2 0.21 表 3 Johnson-Cook材料模型参数

Table 3. Johnson-Cook material model parameters

material A/MPa B/MPa n c m TP 270C 214 356 0.44 0.026 1.08 SUS 821L1 577 1 100 0.50 0.015 0.70 表 4 Gruneisen状态方程参数

Table 4. Parameters of Gruneisen's equation of state

material C0/(m·s-1) S1 γ TP 270C 5 090 1.536 1.23 SUS 821L1 4 569 1.490 2.17 表 5 材料参数

Table 5. Material parameters

material ρ/(g·cm-3) σb/MPa C0/(m·s-1) Hv/GPa Tm/K cp/(J·kg-1·K-1) TP 270C 4.51 601 5 090 1.60 1 941 520 SUS 821L1 7.80 729 4 569 2.94 1 811 500 表 6 不同算法下特征单元峰值速度

Table 6. Peak velocities of feature elements under different algorithms

stand-off distance/mm algorithm vp/(m·s-1) 1.2 ALE 377 SPH-FEM 380 2.2 ALE 422 SPH-FEM 424 3.5 ALE 529 SPH-FEM 537 -

[1] CHEN X, INAO D, TANAKA S, et al. Comparison of explosive welding of pure titanium/SUS 304 austenitic stainless steel and pure titanium/SUS 821L1 duplex stainless steel[J]. Transactions of Nonferrous Metals Society of China, 2021, 31(9): 2687-2702. doi: 10.1016/S1003-6326(21)65685-6 [2] SHERPA B B, KURODA M, IKEDA T, et al. Investigation of interfacial microstructure and mechanical characteristics of Ti/SS316 clads fabricated by explosive welding process[J]. The International Journal of Advanced Manufacturing Technology, 2023, 128(3): 1403-1418. doi: 10.1007/s00170-023-12010-y [3] 陆良宇, 苏勇, 陈健. TA1-304不锈钢爆炸焊接复合板组织和性能的探究[J]. 热加工工艺, 2021, 50(19): 27-30.LU Liangyu, SU Yong, CHEN Jian. Study on microstructure and properties of TA1-304 stainless steel explosive welding cladding plate[J]. Hot Working Technology, 2021, 50(19): 27-30. (in Chinese) [4] 王茹, 郎雪花, 马岚, 等. 大规格高强度钛/纯钛/不锈钢爆炸焊接复合板性能研究[J]. 热加工工艺, 2019, 48(17): 147-149.WANG Ru, LANG Xuehua, MA Lan, et al. Research on performance of large size high strength titanium-pure titanium-stainless steel explosion composite plate[J]. Hot Working Technology, 2019, 48(17): 147-149. (in Chinese) [5] 缪广红, 朱志强, 周大鹏, 等. 基于不同算法的Ti/SS316爆炸焊接数值模拟研究[J]. 精密成形工程, 2024, 16(4): 53-60. doi: 10.3969/j.issn.1674-6457.2024.04.007MIAO Guanghong, ZHU Zhiqiang, ZHOU Dapeng, et al. Numerical simulation of Ti/SS316 explosive welding based on different algorithms[J]. Journal of Netshape Forming Engineering, 2024, 16(4): 53-60. (in Chinese) doi: 10.3969/j.issn.1674-6457.2024.04.007 [6] WANG M J, HU J N, LI K B, et al. Study on the relationship between interface morphology and mechanical properties of explosive welded titanium/duplex stainless steel[J]. The International Journal of Advanced Manufacturing Technology, 2024, 132: 4249-4268. doi: 10.1007/s00170-024-13619-3 [7] 程国强, 李守新. 金属材料在高应变率下的热粘塑性本构模型[J]. 弹道学报, 2004, 16(4): 18-22.CHENG Guoqiang, LI Shouxin. A thermo-viscoplastic constitutive model of metallic materials at high strain rates[J]. Journal of Ballistics, 2004, 16(4): 18-22. (in Chinese) [8] 解江, 潘汉源, 李漩, 等. 内爆载荷作用下泄压容器准静态压力特性[J]. 应用数学和力学, 2023, 44(10): 1236-1249. doi: 10.21656/1000-0887.430359XIE Jiang, PAN Hanyuan, LI Xuan, et al. Quasi-static pressure characteristics of pressure relief vessels under implosion loads[J]. Applied Mathematics and Mechanics, 2023, 44(10): 1236-1249. (in Chinese) doi: 10.21656/1000-0887.430359 [9] 肖云凯, 方秦, 吴昊, 等. Johnson-Cook本构模型参数敏感度分析[J]. 应用数学和力学, 2015, 36(S1): 21-28.XIAO Yunkai, FANG Qin, WU Hao, et al. Parameter sensitivity analysis of Johnson-Cook constitutive model[J]. Applied Mathematics and Mechanics, 2015, 36(S1): 21-28. (in Chinese)) [10] 郑远谋. 爆炸焊接和爆炸复合材料[M]. 北京: 国防工业出版社, 2017: 90-91.ZHENG Yuanmou. Explosive Welding and Explosive Composite Material[M]. Beijing: National Defense Industry Press, 2017: 90-91. (in Chinese) [11] 郭静, 梁斌. 复合板爆炸焊接参数计算窗口开发[J]. 山西冶金, 2021, 44(1): 19-21.GUO Jing, LIANG Bin. Development of calculation window for explosive welding parameters of composite plate[J]. Shanxi Metallurgy, 2021, 44(1): 19-21. (in Chinese) [12] 卞超, 王凤英, 卜杉杉, 等. 钛-钢板爆炸焊接的影响因素及炸药配方[J]. 工程爆破, 2016, 22(1): 73-76.BIAN Chao, WANG Fengying, BU Shanshan, et al. Influence factors and explosive formula of explosive welding of titanium-steel plate[J]. Engineering Blasting, 2016, 22(1): 73-76. (in Chinese) [13] 王宇新, 李晓杰, 王小红, 等. 复合轧辊的爆炸焊接技术研制[J]. 南京理工大学学报, 2019, 43(5): 556-562.WANG Yuxin, LI Xiaojie, WANG Xiaohong, et al. Development of explosive welding technology for composite roll[J]. Journal of Nanjing University of Science and Technology, 2019, 43(5): 556-562. (in Chinese) [14] 缪广红, 马秋月, 胡昱, 等. 铝/不锈钢双金属管爆炸焊接数值模拟[J]. 兵器装备工程学报, 2024, 45(2): 238-245.MIAO Guanghong, MA Qiuyue, HU Yu, et al. Numerical simulation of explosive welding of aluminum/stainless steel bimetallic tubes[J]. Journal of Ordnance Equipment Engineering, 2024, 45(2): 238-245. (in Chinese) [15] SARAVANAN S, RAGHUKANDAN K, HOKAMOTO K. Improved microstructure and mechanical properties of dissimilar explosive cladding by means of interlayer technique[J]. Archives of Civil and Mechanical Engineering, 2016, 16(4): 563-568. http://daneshyari.com/article/preview/245493.pdf [16] 李晓杰, 莫非, 闫鸿浩, 等. 爆炸焊接界面波的数值模拟[J]. 爆炸与冲击, 2011, 31(6): 653-657.LI Xiaojie, MO Fei, YAN Honghao, et al. Numerical simulation of interface wave in explosive welding[J]. Explosive and Shock Waves, 2011, 31(6): 653-657. (in Chinese) -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号