Crashworthiness of Polygonal Rotary Splicing Origami Tubes Under Oblique Low-Speed Impact Loads

-

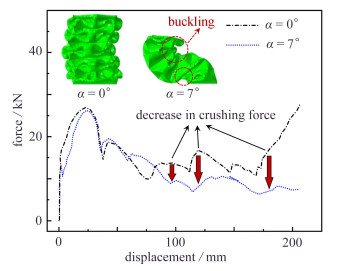

摘要: 为提升车用碰撞盒斜向冲击载荷下耐撞性能,该文创新设计出了一种具有多边形旋转拼接折纸图案的折纸管构型,开展了落锤冲击试验及数值仿真分析. 研究发现,冲击载荷下新型折纸管较传统方管具有优异的耐撞性,且最终产生具有高耐撞性能的钻石模式. 另外,该文对新型折纸管开展了不同冲击角度下几何参数耐撞性影响研究,数值结果表明,新型折纸管折痕高度比和折痕长度比以及宽厚比的参数变化显著影响折纸管耐撞性,并引发不同变形模式;不同冲击角度下,新型折纸管的平均力Fave和峰值力Fmax虽然随着冲击角度θ的增大而逐渐下降,但峰值力Fmax的下降趋势较平均力Fave下降趋势更为显著,且折纸管在不同冲击角度下依旧表现出较高的载荷压溃率ηCFE. 进一步验证了多边形旋转拼接折纸管具有优异的斜向冲击吸能性能.Abstract: To improve the crashworthiness of automotive collision energy absorption boxes under oblique impact loads, a new-type origami tube with a polygonal rotary splicing origami pattern was designed based on conventional square tubes. The drop hammer impact experiment and numerical simulation analysis were conducted to prove the excellent crashworthiness of the new-type origami tube compared with the conventional square tube under impact load, with a high-crashworthiness diamond pattern finally produced. Additionally, the effects of geometric parameters on the crashworthiness of the new-type origami tubes were studied at different impact angles. The numerical results show that, the changes of the crease height ratios, length ratios and width-to-thickness ratios of the origami tube significantly affect the crashworthiness, and lead to different deformation modes. Under different impact angles, average force Fave and initial peak force Fmax of the new-type origami tube gradually decrease with the increase of impact angle θ, but the decline trend of Fmax is more significant than that of Fave, and the origami tube still shows a relatively high crush load efficiency under different impact angles, to further verify that the polygonal rotary splicing origami tube has excellent oblique impact energy absorption performance.

-

Key words:

- oblique impact /

- thin-walled structure /

- origami design /

- crashworthiness

-

表 1 试验件的主要几何尺寸

Table 1. The main geometric dimensions of the specimens

experimental sample a1/mm a2/mm b1/mm b2/mm α/(°) β/(°) L/mm t/mm quality/g PRT-IE1 30 30 30 30 162 162 115.9 0.85 165.7 PRT-IE2 30 30 30 30 162 162 116.1 0.85 169.2 表 2 数值模型主要几何尺寸

Table 2. The main dimensions of the specimen (numerical model)

numerical model a1/mm a2/mm b1/mm b2/mm α/(°) β/(°) L/mm t/mm quality/g PRT-IN-D 30 30 30 30 162 162 116 0.85 169.7 表 3 数值与试验重要指标结果

Table 3. Numerical and experimental significant index results

tube type Fmax/kN error/% Fave/kN error/% ηCFE/% error/% ea/(J/g) error/% CST-IE 59.9 - 11.4 - 19.0 - 6.7 - PRT-IE1 34.6 -42.2 24.2 112.3 69.9 267.9 14.3 113.4 PRT-IE2 35.9 -40.1 24.2 112.3 65.6 245.3 14.3 113.4 PRT-IN-D 33.9 -43.4 26.0 128.1 76.7 303.7 15.3 128.4 表 4 CCB耐撞性能

Table 4. The CCB crashworthiness

tube type θ/(°) Fmax/kN error/% Fave/kN error/% ηCFE/% ea/(J/g) ηEA CCB-0deg 0 391.7 - 147.3 - 37.6 13.3 3.07E-5 CCB-4deg 4 247.9 -36.7 129.9 -11.8 52.4 11.7 2.71E-5 CCB-7deg 7 232.9 -40.5 104.3 -29.2 44.8 9.4 2.18E-5 表 5 不同折痕高度比h1(h3)/h2折纸管的几何尺寸和数值计算结果

Table 5. Dimensions and numerical results for different ratios h1(h3)/h2

tube type h1(h3)/mm h2/mm h1(h3)/h2 θ/(°) Fmax/kN Fave/kN ηCFE/% ea/(J/g) ηEA PRT-1/3h-0deg

PRT-1/3h-4deg

PRT-1/3h-7deg30 90 1/3 0 102.8 111.9 108.9 10.1 2.34E-5 4 89.2 127.4 142.8 11.5 2.66E-5 7 84.2 112.4 133.6 10.1 2.35E-5 PRT-1/2h-0deg

PRT-1/2h-4deg

PRT-1/2h-7deg37.5 75 1/2 0 132.3 127.7 96.5 11.5 2.66E-5 4 117.6 122.4 104.1 11.0 2.55E-5 7 96.9 113.0 116.7 10.2 2.36E-5 PRT-1h-0deg

PRT-1h-4deg

PRT-1h-7deg50 50 1 0 235.6 137.3 58.3 12.4 2.87E-5 4 154.1 133.0 86.3 12.0 2.78E-5 7 135.6 126.7 93.4 11.4 2.64E-5 PRT-11/8h-0deg

PRT-11/8h-4deg

PRT-11/8h-7deg55 40 11/8 0 267.8 143.2 53.5 12.9 2.99E-5 4 162.4 136.2 83.9 12.3 2.84E-5 7 150.3 129.1 85.9 11.7 2.69E-5 PRT-2h-0deg

PRT-2h-4deg

PRT-2h-7deg60 30 2 0 277.9 140.9 50.7 12.7 2.94E-5 4 167.3 133.6 79.9 12.1 2.79E-5 7 162.9 128.8 79.1 11.6 2.69E-5 表 9 耐撞性指标对比

Table 9. Comparison of crashworthiness indexes

tube type Fmax/kN error/% Fave /kN error/% ηCFE/% error/% ea/(J/g) error/% CCB-0deg 391.7 - 147.3 - 37.6 - 13.3 - PRT-ct-49-0deg 112.0 -71.4 183.0 24.2 163.4 334.6 13.4 0.8 表 6 不同折痕长度比a1(b1)/a2(b2)折纸管几何尺寸和数值计算结果

Table 6. Dimensions and numerical results for different ratios a1(b1)/a2(b2)

tube type a1(b1)/mm a2(b2)/mm a1(b1)/a2(b2) θ/(°) Fmax/kN Fave/kN ηCFE/% ea/(J/g) ηEA PRT-1a-0deg

PRT-1a-7deg61.25 61.25 1 0 134.1 119.2 88.9 10.8 2.49E-5 7 121.2 110.6 91.3 10.0 2.31E-5 PRT-2a-0deg

PRT-2a-7deg81.67 40.83 2 0 104.8 114.2 109.0 10.3 2.38E-5 7 96.7 114.0 117.9 10.3 2.38E-5 PRT-3a-0deg

PRT-3a-7deg91.875 60.625 3 0 102.8 111.9 108.9 10.1 2.34E-5 7 84.2 112.4 133.6 10.1 2.35E-5 PRT-4a-0deg

PRT-4a-7deg98 24.5 4 0 92.8 127.7 137.5 11.5 2.66E-5 7 84.4 108.5 128.6 9.8 2.26E-5 PRT-5a-0deg

PRT-5a-7deg102.08 20.42 5 0 91.0 135.6 149.1 12.2 2.83E-5 7 80.1 117.1 146.3 10.6 2.44E-5 表 7 不同宽厚比c/t折纸管几何尺寸和数值计算结果

Table 7. Dimensions and numerical results for different ratios c/t

tube type t/mm c/t Fmax/kN error/% Fave/kN error/% ηCFE/% error/% ea/(J/g) error/% CCB-0deg 2.0 61.3 391.7 - 147.3 - 37.6 - 13.3 - PRT-ct-49 2.5 49.0 112.0 -71.4 183.0 24.2 163.4 334.6 13.4 0.8 PRT-ct-61 2.0 61.3 91.0 -76.8 135.6 -3.0 149.1 296.5 12.2 -8.3 PRT-ct-81 1.5 81.7 45.8 -88.3 78.7 -46.6 171.8 356.9 9.6 -27.8 PRT-ct-122 1.0 122.5 23.8 -93.9 37.4 -28.1 157.1 317.8 6.8 -48.9 PRT-ct-245 0.5 245.0 8.0 -98.0 12.3 -91.6 153.8 309.0 4.5 -66.2 表 8 不同冲击角度对Fmax, Fave, ηCFE和ea的影响结果

Table 8. Effects of different impact angles on Fmax, Fave, ηCFE and ea

tube type θ/(°) Fmax/kN error/% Fave/kN error/% ηCFE/% error/% ea/(J/g) error/% PRT-ct-49-0deg 0 112.0 - 183.0 - 163.4 - 13.4 - PRT-ct-49-10deg 10 40.1 -64.2 146.3 20.1 364.8 123.3 10.7 -20.1 PRT-ct-49-15deg 15 62.0 -44.6 158.8 13.2 256.1 56.7 11.6 -13.4 PRT-ct-49-20deg 20 51.2 -54.3 150.0 18.0 293.0 79.3 10.9 -20.1 PRT-ct-49-25deg 25 36.8 -67.1 119.2 34.9 323.9 98.2 8.7 -35.1 -

[1] 何远鹏, 王凌峰, 杨秋松, 等. 多折角梯形台面折纸夹层结构的冲击防护性能[J]. 爆炸与冲击, 2024, 44 (4): 36-48.HE Yuanpeng, WANG Lingfeng, YANG Qiusong, et al. Impact response of TPS folded sandwich structure[J]. Explosion and Shock Waves, 2024, 44 (4): 36-48. (in Chinese) [2] 霍鹏, 许述财, 范晓文, 等. 鹿角骨单位仿生薄壁管斜向冲击耐撞性研究[J]. 爆炸与冲击, 2020, 40(11): 127-138.HUO Peng, XU Shucai, FAN Xiaowen, et al. Oblique impact resistance of a bionic thin-walled tube based on antles osteon[J]. Explosion and Shock Waves, 2020, 40 (11): 127-138. (in Chinese) [3] 贾豪博, 任柯融, 卿华, 等. 破片冲击作用下油箱动力学响应行为实验研究[J]. 应用数学和力学, 2023, 44 (8): 944-952. doi: 10.21656/1000-0887.440002JIA Haobo, REN Kerong, QING Hua, et al. Experimental study on dynamic responses of fuel tanks under fragment impacts[J]. Applied Mathematics and Mechanics, 2023, 44 (8): 944-952. (in Chinese) doi: 10.21656/1000-0887.440002 [4] YILDIRIM A, DEMIRCI E, KARAGÖZ S, et al. Experimental and numerical investigation of crashworthiness performance for optimal automobile structures using response surface methodology and oppositional based learning differential evolution algorithm[J]. Materials Testing, 2023, 65 (3): 346-363. doi: 10.1515/mt-2022-0304 [5] 张智扬, 赵振宇, 任建伟, 等. 蜂窝夹芯结构用连接接头抗冲击性能研究[J]. 应用数学和力学, 2024, 45 (8): 1024-1036. doi: 10.21656/1000-0887.450131ZHANG Zhiyang, ZHAO Zhenyu, REN Jianwei, et al. Study on impact resistance of connection joints for honeycomb sandwich structures[J]. Applied Mathematics and Mechanics, 2024, 45 (8): 1024-1036. (in Chinese) doi: 10.21656/1000-0887.450131 [6] HAN D C, PARK S H. Collapse behavior of square thin-walled columns subjected to oblique loads[J]. Thin-Walled Structures, 1999, 35 (3): 167-184. doi: 10.1016/S0263-8231(99)00022-1 [7] REYES A, LANGSETH M, HOPPERSTAD O S. Crashworthiness of aluminum extrusions subjected to oblique loading: experiments and numerical analyses[J]. International Journal of Mechanical Sciences, 2002, 44 (9): 1965-1984. doi: 10.1016/S0020-7403(02)00050-4 [8] 柳占立, 初东阳, 王涛, 等. 爆炸和冲击载荷下金属材料及结构的动态失效仿真[J]. 应用数学和力学, 2021, 42 (1): 1-14.LIU Zhanli, CHU Dongyang, WANG Tao, et al. Dynamic failure simulation of metal materials and structures under blast and impact loading[J]. Applied Mathematics and Mechanics, 2021, 42 (1): 1-14. (in Chinese) [9] 杨欣, 范晓文, 许述财, 等. 仿虾螯结构薄壁管设计及耐撞性分析[J]. 爆炸与冲击, 2020, 40 (4): 62-72.YANG Xin, FAN Xiaowen, XU Shucai, et al. Design and crashworthiness analysis of thin-walled tubes based on a shrimp chela structure[J]. Explosion and Shock Waves, 2020, 40 (4): 62-72. (in Chinese) [10] 张筱, 肖勇, 刘洪波, 等. 轴向串联式吸能管的缓冲吸能特性[J]. 爆炸与冲击, 2024, 44 (11): 104-113.ZHANG Xiao, XIAO Yong, LIU Hongbo, et al. Energy absorption characteristics of axial series energy absorption tubes[J]. Explosion and Shock Waves, 2024, 44 (11): 104-113. (in Chinese) [11] SONG Z, MING S, DU K, et al. Energy absorption of metal-composite hybrid tubes with a diamond origami pattern[J]. Thin-Walled Structures, 2022, 180 : 109824. doi: 10.1016/j.tws.2022.109824 [12] TENG C H, SONG Z B, ZHOU C H, et al. The imperfection sensitivity of trapezoid origami crash boxes[J]. Thin-Walled Structures, 2024, 196 : 111486. doi: 10.1016/j.tws.2023.111486 [13] MING S, SONG Z, ZHOU C, et al. The energy absorption of long origami-ending tubes with geometrical imperfections[J]. Thin-Walled Structures, 2021, 161 : 107415. doi: 10.1016/j.tws.2020.107415 [14] YE H, ZHOU X, MA J, et al. Axial crushing behaviors of composite pre-folded tubes made of KFRP/CFRP hybrid laminates[J]. Thin-Walled Structures, 2020, 149 : 106649. doi: 10.1016/j.tws.2020.106649 [15] YAO S, ZHU H, LIU M, et al. Energy absorption of origami tubes with polygonal cross-sections[J]. Thin-Walled Structures, 2020, 157 : 107013. doi: 10.1016/j.tws.2020.107013 [16] YE H T, MA J Y, ZHOU X, et al. Energy absorption behaviors of pre-folded composite tubes with the full-diamond origami patterns[J]. Composite Structures, 2019, 221 : 110904. doi: 10.1016/j.compstruct.2019.110904 [17] MA J Y, DAI H P, SHI M Y, et al. Quasi-static axial crushing of hexagonal origami crash boxes as energy absorption devices[J]. Mechanical Sciences, 2019, 10 (1): 133-143. doi: 10.5194/ms-10-133-2019 [18] YANG K, XU S Q, ZHOU S W, et al. Multi-objective optimization of multi-cell tubes with origami patterns for energy absorption[J]. Thin-Walled Structures, 2018, 123 : 100-113. doi: 10.1016/j.tws.2017.11.005 [19] ZHOU C H, JIANG L L, TIAN K, et al. Origami crash boxes subjected to dynamic oblique loading[J]. Journal of Applied Mechanics, 2017, 84 (9): 091006. doi: 10.1115/1.4037160 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号