A Theoretical Characterization Model for Temperature-Dependent Yield Strengths of Metal Matrix Composites Reinforced With Nanoparticles

-

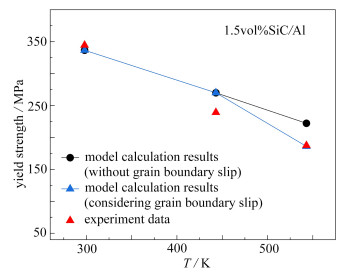

摘要: 通过定量表征宽温域下,各强化机制对纳米颗粒增强金属基复合材料(nanoparticle reinforced metal matrix composites,NRMMCs)的屈服强度以及晶界滑移对金属基体屈服强度的影响,建立了不含拟合参数的NRMMCs温度相关性屈服强度理论表征模型.模型仅需金属基体任意一个参考温度下的屈服强度及相关材料参数,如比热容、热膨胀系数、熔点等,即可预测NRMMCs在任意温度下的屈服强度.模型预测结果与目前获取到的四组所有实验数据均取得了良好的一致性,实现了对NRMMCs宽温域屈服强度的合理预测.在此基础上,探讨了主要强化机制对NRMMCs屈服强度的影响及其随温度和颗粒尺寸的演化规律,为设计和开发适用于宽温域下的NRMMCs提供了理论依据和有效建议.

-

关键词:

- 纳米颗粒增强金属基复合材料 /

- 温度相关性 /

- 屈服强度 /

- 理论表征模型 /

- 强化机制

Abstract: Through quantitative characterization of the effects of various strengthening mechanisms on the yield strengths of nanoparticle-reinforced metal matrix composites (NRMMCs) within a wide temperature range, as well as the impacts of grain boundary sliding on the yield strength of the metal matrix, a theoretical characterization model for the temperature-dependent yield strengths of NRMMCs without fitting parameters was established. This model only requires the yield strength of the metal matrix at any one reference temperature and relevant material parameters such as the specific heat capacity, the thermal expansion coefficient, and the melting point, etc., to predict the yield strengths of the NRMMCs at any temperature. The predicted results of the model are in good agreement with all the 4 sets of experimental data currently available, achieving a reasonable prediction of the yield strengths of the NRMMCs within a wide temperature range. On this basis, the effects of the main strengthening mechanisms on the yield strengths of the NRMMCs and their evolution laws with the temperature and the particle size were discussed, to provide a theoretical basis and effective suggestions for the design and development of NRMMCs applicable to a wide temperature range.-

Key words:

- nanoparticle reinforced metal matrix composite /

- temperature dependence /

- yield strength /

- theoretical characterization model /

- reinforcement mechanism

edited-byedited-by1) (我刊编委李卫国来稿) -

表 1 预测不同温度环境下屈服强度所需的材料参数(铝合金的晶界能γgbs(T0)为1.8 J/m2[29])

Table 1. Material parameters used to predict the yield strength in different temperature environments (for aluminum alloy, grain boundary energy γgbs(T0) is 1.8 J/m2[29])

material parameter 1.5vol%SiC/Al 3vol%SiC/Al 3.2vol%TiB2/2618Al 0.5vol%SiCp/2014Al σm(T0)/MPa 237(T0=298 K)[30] 237(T0=298 K)[30] 306.5(T0=298 K)[31] 182(T0=493 K)[32] Tm/K[28] 933 933 933 933 ΔHM/J[28] 10 711 10 711 10 711 10 711 Em(T0)/GPa 55.5[30] 55.5[30] 75.7[31] - υm[31] 0.33 0.33 0.33 0.33 β(T0)/(MPa·m0.5)[27] 0.06 0.06 0.06 0.06 dc/μm 0.081[30] 0.073[30] 11.4[31] 53[32] dm/μm 0.099[30] 0.099[30] 42.6[31] 122[32] dp/nm 50[30] 50[30] 700[31] 40[32] Burgers vector/nm[33] 0.286 0.286 0.286 0.286 Δα/K-1 1.73×10-5[33-34] 1.73×10-5[33-34] 1.62×10-5[31] 1.73×10-5[33-34] Tprocess/K 773[30] 773[30] 778[31] 653[32] -

[1] JIAO Y, HUANG L, GENG L. Progress on discontinuously reinforced titanium matrix composites[J]. Journal of Alloys and Compounds, 2018, 767 : 1196-1215. doi: 10.1016/j.jallcom.2018.07.100 [2] TJONG S C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets[J]. Materials Science and Engineering R: Reports, 2013, 74(10): 281-350. doi: 10.1016/j.mser.2013.08.001 [3] RAVIRAJ S, ADITHYA H, KUMAR S S U, et al. Processing and mechanical characterisation of titanium metal matrix composites: a literature review[J]. Journal of Composites Science, 2022, 6(12): 388. doi: 10.3390/jcs6120388 [4] RAMESH C S, ADARSHA H, PRAMOD S, et al. Tribological characteristics of innovative Al6061-carbon fiber rod metal matrix composites[J]. Materials & Design, 2013, 50 : 597-605. [5] HASSAN S F, TAN M J, GUPTA M. High-temperature tensile properties of Mg/Al2O3 nanocomposite[J]. Materials Science and Engineering A, 2008, 486(1/2): 56-62. [6] OÑORO J, SALVADOR M, CAMBRONERO L. High-temperature mechanical properties of aluminium alloys reinforced with boron carbide particles[J]. Materials Science & Engineering A, 2008, 499(1): 421-426. [7] CASATI R, FIOCCHI J, FABRIZI A, et al. Effect of ball milling on the ageing response of Al2618 composites reinforced with SiC and oxide nanoparticles[J]. Journal of Alloys and Compounds, 2017, 693 : 909-920. doi: 10.1016/j.jallcom.2016.09.265 [8] YU H, ZHOU H, SUN Y, et al. Microstructures and mechanical properties of ultrafine-grained Ti/AZ31 magnesium matrix composite prepared by powder metallurgy[J]. Advanced Powder Technology, 2018, 29(12): 3241-3249. [9] ZHANG Z, CHEN D. Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: a model for predicting their yield strength[J]. Scripta Materialia, 2006, 54(7): 1321-1326. doi: 10.1016/j.scriptamat.2005.12.017 [10] HASSANZADEH-AGHDAM M K, MAHMOODI M J, ANSARI R. A comprehensive predicting model for thermomechanical properties of particulate metal matrix nanocomposites[J]. Journal of Alloys and Compounds, 2018, 739 : 164-177. doi: 10.1016/j.jallcom.2017.12.232 [11] CLYNE T W, WITHERS P J. An Introduction to Metal Matrix Composites[M]. Cambridge: Cambridge University Press, 1993. [12] GOH C, WEI J, LEE L, et al. Properties and deformation behaviour of Mg-Y2O3 nanocomposites[J]. Acta Materialia, 2007, 55(15): 5115-5121. [13] DAI L, LING Z, BAI Y L. Size-dependent inelastic behavior of particle-reinforced metal-matrix composites[J]. Composites Science and Technology, 2001, 61(8): 1057-1063. doi: 10.1016/S0266-3538(00)00235-9 [14] SANATY-ZADEH A. Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall-Petch effect[J]. Materials Science & Engineering A, 2011, 531 : 112-118. [15] MALAKI M, XU W, KASAR A, et al. Advanced metal matrix nanocomposites[J]. Metals, 2019, 9(3): 330. doi: 10.3390/met9030330 [16] ZHANG X, LI W, MA J, et al. A novel temperature dependent yield strength model for metals considering precipitation strengthening and strain rate[J]. Computational Materials Science, 2017, 129 : 147-155. doi: 10.1016/j.commatsci.2016.12.005 [17] PAN D, MA Y L, ZHANG X Y, et al. Theoretical prediction method of Young's modulus and yield strength of micron particle reinforced metal matrix composites at different temperatures[J]. Composite Structures, 2023, 316 : 117051. [18] ZHANG X, LI W, MA J, et al. Modeling the effects of grain boundary sliding and temperature on the yield strength of high strength steel[J]. Journal of Alloys and Compounds, 2021, 851 : 156747. doi: 10.1016/j.jallcom.2020.156747 [19] LIU H, WANG A, WANG L, et al. The syntheses of SiCp/Al nanocomposites under high pressure[J]. Journal of Materials Research, 1997, 12(5): 1187-1190. doi: 10.1557/JMR.1997.0166 [20] ZHANG Z, CHEN D L. Contribution of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites[J]. Materials Science and Engineering A, 2008, 483 : 148-152. [21] RAMAKRISHNAN N. An analytical study on strengthening of particulate reinforced metal matrix composites[J]. Acta Materialia, 1996, 44(1): 69-77. doi: 10.1016/1359-6454(95)00150-9 [22] KIM C S, SOHN I, NEZAFATI M, et al. Prediction models for the yield strength of particle-reinforced unimodal pure magnesium (Mg) metal matrix nanocomposites (MMNCs)[J]. Journal of Materials Science, 2013, 48(12): 4191-4204. doi: 10.1007/s10853-013-7232-x [23] FU E G, LI N, MISRA A, et al. Mechanical properties of sputtered Cu/V and Al/Nb multilayer films[J]. Materials Science and Engineering A, 2008, 493(1/2): 283-287. [24] TAYEH T, DOUIN J, JOUANNIGOT S, et al. Hardness and Young's modulus behavior of Al composites reinforced by nanometric TiB2 elaborated by mechanosynthesis[J]. Materials Science and Engineering A, 2014, 591 : 1-8. [25] RAJ R, THAKUR D G. Effect of particle size and volume fraction on the strengthening mechanisms of boron carbide reinforced aluminum metal matrix composites[J]. Proceedings of the Institution of Mechanical Engineers (Part C): Journal of Mechanical Engineering Science, 2019, 233(4): 1345-1356. doi: 10.1177/0954406218771997 [26] ASHBY M F. The deformation of plastically non-homogeneous materials[J]. The Philosophical Magazine: A Journal of Theoretical Experimental and Applied Physics, 1970, 21(170): 399-424. [27] LIN T C, CAO C, SOKOLUK M, et al. Aluminum with dispersed nanoparticles by laser additive manufacturing[J]. Nature Communications, 2019, 10 : 4124. [28] 叶大伦, 胡建华. 实用无机物热力学数据手册[M]. 2版. 北京: 冶金工业出版社, 2002.YE Dalun, HU Jianhua. Practical Manual of Inorganic Thermodynamic Data[M]. 2nd ed. Beijing: Metallurgical Industry Press, 2002. (in Chinese)) [29] SRIDHARAN N, GUSSEV M N, PARISH C M, et al. Evaluation of microstructure stability at the interfaces of Al-6061 welds fabricated using ultrasonic additive manufacturing[J]. Materials Characterization, 2018, 139 : 249-258. [30] SOLTANI M, ATRIAN A. High temperature tensile behavior and microstructure of Al-SiC nanocomposite fabricated by mechanical milling and hot extrusion technique[J]. Materials Research Express, 2018, 5(2): 025026. [31] MA S, DAI J, ZHANG C, et al. Enhanced high temperature mechanical properties and heat resistance of an Al-Cu-Mg-Fe-Ni matrix composite reinforced with in situ TiB2 particles[J]. Journal of Materials Science, 2023, 58(32): 13019-13039. [32] ZHANG L J, QIU F, WANG J G, et al. High strength and good ductility at elevated temperature of nano-SiCp/Al2014 composites fabricated by semi-solid stir casting combined with hot extrusion[J]. Materials Science and Engineering A, 2015, 626 : 338-341. [33] PARK J G, KEUM D H, LEE Y H. Strengthening mechanisms in carbon nanotube-reinforced aluminum composites[J]. Carbon, 2015, 95 : 690-698. [34] LLOYD D J. Particle reinforced aluminium and magnesium matrix composites[J]. International Materials Reviews, 1994, 39(1): 1-23. [35] BHARATH V, AJAWAN S S, NAGARAL M, et al. Characterization and mechanical properties of 2014 aluminum alloy reinforced with Al2O3p composite produced by two-stage stir casting route[J]. Journal of the Institution of Engineersp (Indiap): Series C, 2019, 100(2): 277-282. [36] HUANG Y, SUN X, CHANG Y, et al. High thermal stability and mechanical properties of nanosized-Fe-reinforced aluminum matrix composites via deformation-driven metallurgy[J]. Materials Science and Engineering A, 2024, 913 : 147092. [37] SURAPPA M K. Aluminium matrix composites: challenges and opportunities[J]. Sadhana, 2003, 28(1): 319-334. -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号