A Design Method for Conformal Lattice Variable Density Control of Irregular Structures

-

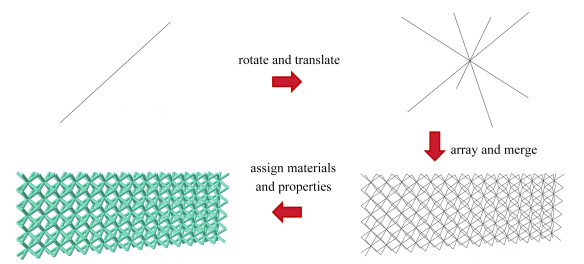

摘要: 针对异形承载结构中存在的共形点阵建模填充复杂、大规模单胞导致设计变量激增、优化困难的问题,提出了一种基于函数描述的共形点阵变密度调控设计方法. 通过发展基于网格变形的共形点阵参数化建模方法,可实现异形结构的点阵快速填充;进一步提出了基于分段三次Hermite插值多项式的点阵单胞尺寸调控方法和基于代理模型的点阵杆径调控方法,可实现点阵的精细调控和设计变量降维;在此基础上,建立了基于自适应更新动态代理模型的点阵结构优化设计框架,实现了点阵调控参数的快速优化设计. 通过两个工程算例开展了算例验证,包括火箭有效载荷适配器应变能优化、飞行器异形承载舱段结构屈曲优化,综合计算结果表明了所提方法对于不同问题的有效性.Abstract: To address the challenges of complex modeling and filling of conformal lattices in irregular load-bearing structures, as well as the difficulty in optimization caused by a surge in design variables due to large-scale unit cells, a conformal lattice variable density control design method based on functional descriptions was proposed. The parametric modeling method for conformal lattices based on mesh deformation was developed, enabling rapid lattice filling for irregular structures. Furthermore, a lattice unit cell size control method based on piecewise cubic Hermite interpolating polynomials and a lattice rod diameter control method based on surrogate models were proposed, to achieve fine control of the lattice and dimensionality reduction of design variables. On this basis, an optimization design framework for lattice structures based on an adaptively updated dynamic surrogate model was established, to realize rapid optimization design of lattice control parameters. Two engineering case studies, including the strain energy optimization of rocket payload adapters and the buckling optimization of irregular load-bearing cabin structures for aircraft, validates the proposed method. The comprehensive computational results show the effectiveness of the proposed method for different problems.

-

Key words:

- irregular structure lattice filling /

- conformal lattice modeling /

- variable density control design /

- surrogate model optimization

edited-byedited-by1) (我刊编委郝鹏来稿) -

表 1 点阵夹芯圆台结构应变能优化结果

Table 1. Optimization results of strain energy for lattice sandwich truncated cone structures

initial lattice structure optimized by the proposed method optimized by differential method lattice structure

strain energy/mJ 1 645 1 248 1 330 strain energy reduction rate/% - 24.13 19.15 mass/kg 51.3 50.7 51.3 θ/(°) 46.5 40.0 46.5 number of iterations - 596 50 number of analysis - 596 5 000 表 2 点阵夹芯椭圆舱段结构屈曲特征值优化结果

Table 2. Optimization results of buckling eigenvalues for lattice sandwich elliptical cabin structures

initial lattice structure optimized with the proposed method lattice structure

1st-order buckling eigenvalue 1.14 1.94 eigenvalue increase rate/% - 70.2 mass/kg 19.1 18.9 θ/(°) 39.2 40.2 number of iterations - 361 -

[1] DU PLESSIS A, BROECKHOVEN C, YADROITSAVA I, et al. Beautiful and functional: a review of biomimetic design in additive manufacturing[J]. Additive Manufacturing, 2019, 27:408-427. [2] MACONACHIE T, LEARY M, LOZANOVSKI B, et al. SLM lattice structures: properties, performance, applications and challenges[J]. Materials & Design, 2019, 183:108137. [3] 张雨明, 吴锐. 我国3D打印技术研究及产业化发展现状[J]. 中国材料进展, 2018, 37(3): 237-240.ZHANG Yuming, WU Rui. Research and industrialization development status of 3D printing technology in China[J]. Materials China, 2018, 37(3): 237-240. (in Chinese) [4] YANG S, ZHAO Y F. Additive manufacturing-enabled design theory and methodology: a critical review[J]. The International Journal of Advanced Manufacturing Technology, 2015, 80:327-342. doi: 10.1007/s00170-015-6994-5 [5] SMITH M, GUAN Z, CANTWELL W J. Finite element modelling of the compressive response of lattice structures manufactured using the selective laser melting technique[J]. International Journal of Mechanical Sciences, 2013, 67:28-41. [6] 柏龙, 熊飞, 陈晓红, 等. SLM制备的Ti6Al4V轻质点阵结构多目标结构优化设计研究[J]. 机械工程学报, 2018, 54(5): 156-165.BAI Long, XIONG Fei, CHEN Xiaohong, et al. Multi-objective structural optimization design of Ti6Al4V lattice structure formed by SLM[J]. Journal of Mechanical Engineering, 2018, 54(5): 156-165. (in Chinese) [7] WETTERGREEN M A, BUCKLEN B S, SUN W, et al. Computer-aided tissue engineering of a human vertebral body[J]. Annals of Biomedical Engineering, 2005, 33(10): 1333-1343. doi: 10.1007/s10439-005-6744-1 [8] WANG H Q, CHEN Y, ROSEN D W. A hybrid geometric modeling method for large scale conformal cellular structures[C]// 25 th Computers and Information in Engineering Conference, Parts A and B. Long Beach, California, USA. ASMEDC, 2005, 3:421-427. [9] LIANG Y, ZHAO F, YOO D J, et al. Design of conformal lattice structures using the volumetric distance field based on parametric solid models[J]. Rapid Prototyping Journal, 2020, 26(6): 1005-1017. [10] CHEN W J, ZHENG X N, LIU S T. Finite-element-mesh based method for modeling and optimization of lattice structures for additive manufacturing[J]. Materials, 2018, 11(11): 2073. [11] VOGIATZIS P, MA M, CHEN S K, et al. Computational design and additive manufacturing of periodic conformal metasurfaces by synthesizing topology optimization with conformal mapping[J]. Computer Methods in Applied Mechanics and Engineering, 2018, 328:477-497. doi: 10.1016/j.cma.2017.09.012 [12] OH S H, HA J W, PARK K. Adaptive conformal cooling of injection molds using additively manufactured TPMS structures[J]. Polymers, 2022, 14(1): 181. doi: 10.3390/polym14010181 [13] LI D W, LIAO W H, DAI N, et al. Anisotropic design and optimization of conformal gradient lattice structures[J]. Computer-Aided Design, 2020, 119:102787. doi: 10.1016/j.cad.2019.102787 [14] WANG H Q, ROSEN D W. Parametric modeling method for truss structures[C]// 22 nd Computers and Information in Engineering Conference. Montreal, Quebec, Canada. ASMEDC, 2002, 1:759-767. [15] ALZAHRANI M, CHOI S K, ROSEN D W. Design of truss-like cellular structures using relative density mapping method[J]. Materials & Design, 2015, 85:349-360. [16] WANG Y, XU H, PASINI D. Multiscale isogeometric topology optimization for lattice materials[J]. Computer Methods in Applied Mechanics and Engineering, 2017, 316:568-585. doi: 10.1016/j.cma.2016.08.015 [17] HUANG X, RADMAN A, XIE Y M. Topological design of microstructures of cellular materials for maximum bulk or shear modulus[J]. Computational Materials Science, 2011, 50(6): 1861-1870. doi: 10.1016/j.commatsci.2011.01.030 [18] WANG C, ZHU J H, ZHANG W H, et al. Concurrent topology optimization design of structures and non-uniform parameterized lattice microstructures[J]. Structural and Multidisciplinary Optimization, 2018, 58:35-50. doi: 10.1007/s00158-018-2009-0 [19] CHEN W, TONG L, LIU S. Concurrent topology design of structure and material using a two-scale topology optimization[J]. Computers & Structures, 2017, 178:119-128. [20] NGUYEN J, PARK S, ROSEN D. Heuristic optimization method for cellular structure design of light weight components[J]. International Journal of Precision Engineering and Manufacturing, 2013, 14:1071-1078. doi: 10.1007/s12541-013-0144-5 [21] 冯琪翔. 基于选择性激光熔化的金属多孔结构力学特性及其变密度设计方法研究[D]. 重庆: 重庆大学, 2017.FENG Qixiang. A study on the mechanical properties of metallic porous structures fabricated using selective laser melting and its variable-density design method[D]. Chongqing: Chongqing University, 2017. (in Chinese) [22] JIN X, LI G X, ZHANG M. Optimal design of three-dimensional non-uniform nylon lattice structures for selective laser sintering manufacturing[J]. Advances in Mechanical Engineering, 2018, 10(7): 1687814018790833. doi: 10.1177/1687814018790833 [23] 易辉成, 龚艳丽, 李康. 基于应力分布的变密度点阵结构优化设计[J]. 机械设计, 2023, 40(4): 105-111.YI Huicheng, GONG Yanli, LI Kang. Structure optimal design of variable density lattice based on stress distribution[J]. Journal of Machine Design, 2023, 40(4): 105-111. (in Chinese) [24] TERRIAULT P, BRAILOVSKI V. Modeling and simulation of large, conformal, porosity-graded and lightweight lattice structures made by additive manufacturing[J]. Finite Elements in Analysis and Design, 2018, 138:1-11. [25] 郑啸男, 程春红, 徐文华. 基于MIST方法的梯度点阵结构优化设计方法[J]. 电子机械工程, 2024, 40(3): 28-32.ZHENG Xiaonan, CHENG Chunhong, XU Wenhua. Optimization method for gradient lattice structure based on MIST[J]. Electro-Mechanical Engineering, 2024, 40(3): 28-32. (in Chinese) [26] 刘大川. 曲线加筋结构的智能优化设计研究[D]. 大连: 大连理工大学, 2023.LIU Dachuan. Research on intelligent optimization design of curved stiffened structures[D]. Dalian: Dalian University of Technology, 2023. (in Chinese) [27] FRITSCH F N, CARLSON R E. Monotone piecewise cubic interpolation[J]. SIAM Journal on Numerical Analysis, 1980, 17(2): 238-246. doi: 10.1137/0717021 [28] 汪大典. 基于Kriging代理模型的结构非概率可靠性分析方法研究[D]. 成都: 电子科技大学, 2022.WANG Dadian. Research on non-probabilistic reliability analysis method of structure based on Kriging surrogate model[D]. Chengdu: University of Electronic Science and Technology of China, 2022. (in Chinese) [29] LEARY M, BABAEE M, BRANDT M, et al. Feasible build orientations for self-supporting fused deposition manufacture: a novel approach to space-filling tesselated geometries[J]. Advanced Materials Research, 2013, 633:148-168. doi: 10.4028/www.scientific.net/AMR.633.148 [30] 杨鑫, 马文君, 王岩, 等. 增材制造金属点阵多孔材料研究进展[J]. 材料导报, 2021, 35(7): 7114-7120.YANG Xin, MA Wenjun, WANG Yan, et al. Research progress of metal lattice porous materials for additive manufacturing[J]. Materials Reports, 2021, 35(7): 7114-7120. (in Chinese) [31] 胡杰, 刘昆, 杜训柏, 等. U型激光焊接夹层板极限强度试验研究[J]. 舰船科学技术, 2016, 38(12): 53-58.HU Jie, LIU Kun, DU Xunbo, et al. Ultimate strength tests of laser-welded corrugated-U type-core sandwich panels[J]. Ship Science and Technology, 2016, 38(12): 53-58. (in Chinese) [32] YIN S, CHEN H Y, WU Y B, et al. Introducing composite lattice core sandwich structure as an alternative proposal for engine hood[J]. Composite Structures, 2018, 201:131-140. doi: 10.1016/j.compstruct.2018.06.038 [33] WANG C, ZHU J, WU M, et al. Multi-scale design and optimization for solid-lattice hybrid structures and their application to aerospace vehicle components[J]. Chinese Journal of Aeronautics, 2021, 34(5): 386-398. doi: 10.1016/j.cja.2020.08.015 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号