Mechanical Property Prediction of Metal Cutting Based on Numerical Simulation and Decision Tree Regression

-

摘要: 快速预测金属切削的各种力学性能对工业制造的优化设计和产能提高十分关键. 当前相关预测模型通常需要昂贵且耗时的实验和分析过程. 构建了一种基于金属切削模拟和决策树回归(decision tree regression, DTR)的预测模型,用于获取不同切削工况下的力学性能. 首先,采用自适应光滑粒子流体动力学(adaptive smoothed particle hydrodynamics, ASPH)模拟金属切削过程,捕获了不同模拟参数下的多种力学性能,组成2 000种切削工况的模拟数据集;其次,利用DTR算法学习模拟数据集,训练和构建金属切削预测模型,并通过交叉验证和网格搜索评估了不同剪枝策略下预测模型的效果. 结果表明,建立的预测模型可以快速地预测不同模拟参数下的多种力学性能,适宜的剪枝策略可以提升预测模型的准确度、泛化能力和稳定性.

-

关键词:

- 金属切削 /

- 力学性能预测 /

- 数值模拟 /

- 自适应光滑粒子流体动力学 /

- 决策树回归

Abstract: Rapid prediction of mechanical properties of metal cutting is critical to optimal design and productivity improvement of industrial manufacturing. Current prediction models often require expensive and time-consuming experimental and analytical processes. A prediction model based on metal cutting simulation and decision tree regression was constructed to obtain mechanical properties under different cutting conditions. Firstly, the adaptive smoothed particle hydrodynamics (ASPH) was used to simulate the metal cutting process, capture a variety of mechanical properties under different simulation parameters, and form a simulation dataset of 2 000 cutting conditions. Secondly, the decision tree regression (DTR) was used to learn the simulation data set, train and construct the metal cutting prediction model, and evaluate the effect of the prediction model under different pruning strategies by cross-validation and grid search. The results show that, the established prediction model can quickly predict multi-mechanical properties under different simulation parameters, and the appropriate pruning strategy can improve the accuracy, generalization ability and stability of the prediction model.-

Key words:

- metal cutting /

- mechanical property prediction /

- numerical simulation /

- adaptive smoothed particle hydrodynamics /

- decision tree regression

edited-byedited-by1) (我刊编委冯志强来稿) -

表 1 现有方法应用于金属切削时的特点对比

Table 1. A comparison of the characteristics of existing methods applied to metal cutting

method strength limitation classical theory establishes analytical cutting models incomplete characterization of phenomena numerical simulation acquires internal workpiece data elevated computational cost artificial intelligence enables data-driven prediction suboptimal model performance 表 2 金属切削模拟中Ti6Al4V钛合金的材料参数

Table 2. Material parameters of the Ti6Al4V titanium alloy in the metal cutting simulation

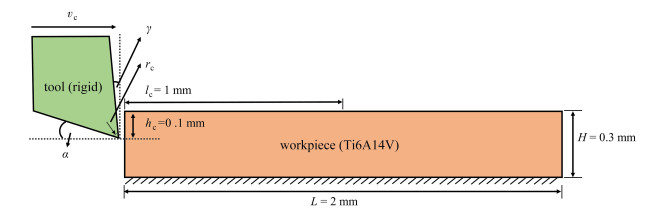

property unit value property unit value coefficient of friction - 0.35 MJC A MPa 724.7 workpiece density kg/m3 4 430 MJC B MPa 683.1 Young’s modulus GPa 113.8 MJC C - 0.035 Poisson’s ratio - 0.35 MJC m - 1 heat conductivity W/(m·K) 7.3 MJC n - 0.47 specific heat capacity J/(kg·K) 580 MJC a - 2 reference temperature K 298 MJC b - 5 melting temperature K 1 878 MJC c - 2 Taylor-Quinney factor - 0.9 MJC d - 1 MJC s - 0.05 表 3 模拟参数的取值范围

Table 3. The value range of the simulation parameter

property symbol value cutting speed vc/(m/min) 5.0×102, 6.0×102, 7.0×102, 8.0×102, 9.0×102 cutting-edge radius rc/m 5.0×10-6, 1.0×10-5 rake angle α/(°) 1.0×10-5, 5.0×10-5 clearance angle γ/(°) 9, 10, 11, 12, 13 particle spacing Δx/m 2.5×10-5, 2.0×10-5, 1.25×10-5, 1.0×10-5, 6.25×10-6 adaptive scheme as 1, 2, 3, 4 表 4 预测模型在不同决策树结构参数的R2分数、输入特征重要性和计算时间

Table 4. The R2 scores, input feature importance and computation time of the prediction model with different decision tree structure parameters

parameter score input feature importance speed train test vc rc α γ Δx as default 1.000 -0.089 0.201 0.048 0.209 0.100 0.273 0.169 0.007 868 depth is 3 0.395 0.388 0.351 0.000 0.000 0.000 0.649 0.000 0.004 001 depth is 4 0.464 0.445 0.364 0.006 0.000 0.000 0.552 0.078 0.004 002 depth is 5 0.497 0.458 0.381 0.017 0.002 0.000 0.522 0.078 0.004 002 depth is 6 0.528 0.449 0.368 0.036 0.010 0.000 0.493 0.093 0.004 003 depth is 7 0.568 0.439 0.347 0.046 0.029 0.012 0.461 0.106 0.004 005 depth is 8 0.632 0.375 0.314 0.053 0.062 0.036 0.416 0.119 0.004 005 depth is 5, split is 2, leaf is 25 0.496 0.459 0.380 0.017 0.002 0.000 0.523 0.078 0.003 999 depth is 6, split is 60, leaf is 28 0.510 0.458 0.379 0.027 0.002 0.001 0.512 0.080 0.003 998 depth is 7, split is 60, leaf is 28 0.513 0.457 0.376 0.026 0.002 0.003 0.510 0.082 0.004 001 depth is 8, split is 60, leaf is 28 0.513 0.457 0.376 0.026 0.002 0.003 0.510 0.082 0.004 000 表 5 预测模型在不同决策树结构参数下对输出标签的MAPE

Table 5. The MAPE of the output label of the prediction model with different decision tree structure parameters

parameter Fc Ft T S E Vx Vy default 0.088 5 0.237 3 0.025 9 0.006 8 0.132 2 0.183 1 0.234 7 depth is 3 0.074 5 0.174 5 0.022 0 0.004 7 0.113 5 0.142 1 0.169 3 depth is 4 0.064 2 0.166 2 0.022 1 0.004 6 0.112 4 0.129 7 0.161 9 depth is 5 0.064 1 0.168 2 0.020 6 0.004 6 0.109 3 0.122 4 0.160 8 depth is 6 0.065 9 0.165 2 0.020 0 0.004 8 0.104 9 0.116 1 0.164 0 depth is 7 0.067 7 0.165 2 0.019 7 0.004 9 0.101 2 0.119 2 0.162 2 depth is 8 0.070 2 0.171 5 0.020 1 0.005 0 0.103 3 0.128 0 0.173 6 depth is 5, split is 2, leaf is 25 0.063 8 0.168 3 0.020 6 0.004 6 0.109 3 0.122 4 0.160 9 depth is 6, split is 60, leaf is 28 0.065 2 0.164 9 0.020 2 0.004 7 0.107 8 0.115 9 0.160 7 depth is 7, split is 60, leaf is 28 0.065 3 0.166 4 0.019 7 0.004 7 0.108 8 0.115 0 0.160 1 depth is 8, split is 60, leaf is 28 0.065 3 0.166 4 0.019 7 0.004 7 0.108 8 0.115 0 0.160 1 -

[1] MOHANTA D K, PANI B, SAHOO B, et al. A critical study on computation of cutting forces in metal cutting[J]. Journal of Physics: Conference Series, 2021, 2070(1): 012166. doi: 10.1088/1742-6596/2070/1/012166 [2] JAMWAL A, AGRAWAL R, SHARMA M, et al. Application of optimization techniques in metal cutting operations: a bibliometric analysis[J]. Materials Today: Proceedings, 2021, 38:365-370. doi: 10.1016/j.matpr.2020.07.425 [3] 张建飞. Ti6Al4V高速切削过程有限元模拟及切削参数优化[D]. 昆明: 昆明理工大学, 2017.ZHANG Jianfei. Finite element simulation of high speed machining Ti6Al4V and optimization of cutting parameters[D]. Kunming: Kunming University of Science and Technology, 2017. (in Chinese) [4] WEN D Y, WAN M, REN Y Y, et al. Material piling up and spreading effects in the cutting processes with small feed rates[J]. Mechanical Systems and Signal Processing, 2022, 171:108839. doi: 10.1016/j.ymssp.2022.108839 [5] WEI X Y, MIAO E M, YE H H. Analytical prediction of three dimensional chatter stability considering multiple parameters in milling[J]. International Journal of Precision Engineering and Manufacturing, 2022, 23(7): 711-720. doi: 10.1007/s12541-022-00645-y [6] 冯广贵. 考虑切削速度的铣削力建模方法与实验研究[D]. 武汉: 华中科技大学, 2022.FENG Guanggui. A dissertation submitted in partial fulfillment of the requirements for the professional master degree[D]. Wuhan: Huazhong University of Science and Technology, 2022. (in Chinese) [7] TAWARA D, TAKANO N, KINOSHITA H, etal. Stochastic multi-scale finite element analysis of the drilling force of trabecular bone during oral implant surgery[J]. International Journal of Applied Mechanics, 2016, 8(6): 1650075. doi: 10.1142/S1758825116500757 [8] CARBONELL J M, RODRÍGUEZ J M, OÑATE E. Modelling 3D metal cutting problems with the particle finite element method[J]. Computational Mechanics, 2020, 66(3): 603-624. doi: 10.1007/s00466-020-01867-5 [9] CHENG W, OUTEIRO J C. Modelling orthogonal cutting of Ti-6Al-4V titanium alloy using a constitutive model considering the state of stress[J]. The International Journal of Advanced Manufacturing Technology, 2022, 119(7): 4329-4347. [10] DU H H, SUET T, YIN T F, ET al. Microstructured surface generation and cutting force prediction of pure titanium TA2[J]. Precision Engineering, 2022, 75:101-110. doi: 10.1016/j.precisioneng.2022.02.004 [11] WANG H, DONG Z, YUAN S, et al. Effects of tool geometry on tungsten removal behavior during nano-cutting[J]. International Journal of Mechanical Sciences, 2022, 225:107384. doi: 10.1016/j.ijmecsci.2022.107384 [12] AJITH ARUL DANIEL S, PUGAZHENTHI R, KUMAR R, et al. Multi objective prediction and optimization of control parameters in the milling of aluminium hybrid metal matrix composites using ANN and Taguchi-grey relational analysis[J]. Defence Technology, 2019, 15(4): 545-556. doi: 10.1016/j.dt.2019.01.001 [13] 赵海越, 曹岩, 黄亮, 等. 基于遗传算法的ZL205A铝合金切削参数多目标优化[J]. 兵器材料科学与工程, 2023, 46(5): 58-65.ZHAO Haiyue, CAO Yan, HUANG Liang, et al. Multi-objective optimization of ZL205A aluminum alloy cutting parameters based on genetic algorithm[J]. Ordnance Material Science and Engineering, 2023, 46(5): 58-65. (in Chinese) [14] XIE J, HU P, CHEN J, et al. Deep learning-based instantaneous cutting force modeling of three-axis CNC milling[J]. International Journal of Mechanical Sciences, 2023, 246:108153. doi: 10.1016/j.ijmecsci.2023.108153 [15] BUCHKREMER S, KLOCKE F, LUNG D. Analytical study on the relationship between chip geometry and equivalent strain distribution on the free surface of chips in metal cutting[J]. International Journal of Mechanical Sciences, 2014, 85:88-103. doi: 10.1016/j.ijmecsci.2014.05.005 [16] HU C, ZHUANG K, WENG J, et al. Cutting temperature prediction in negative-rake-angle machining with chamfered insert based on a modified slip-line field model[J]. International Journal of Mechanical Sciences, 2020, 167:105273. doi: 10.1016/j.ijmecsci.2019.105273 [17] CHEN Y, WANG J, AN Q. Mechanisms and predictive force models for machining with rake face textured cutting tools under orthogonal cutting conditions[J]. International Journal of Mechanical Sciences, 2021, 195:106246. doi: 10.1016/j.ijmecsci.2020.106246 [18] LI Y, ZHANG X, WANG C. Cutting force prediction model for elliptical vibration cutting SiCp/Al based on three-phase friction theory[J]. Applied Sciences, 2021, 11(22): 10737. doi: 10.3390/app112210737 [19] JIN X, ALTINTAS Y. Prediction of micro-milling forces with finite element method[J]. Journal of Materials Processing Technology, 2012, 212(3): 542-552. doi: 10.1016/j.jmatprotec.2011.05.020 [20] AYDIN M, KÖKLÜ U. Analysis of flat-end milling forces considering chip formation process in high-speed cutting of Ti6Al4V titanium alloy[J]. Simulation Modelling Practice and Theory, 2020, 100:102039. doi: 10.1016/j.simpat.2019.102039 [21] OJAL N, COPENHAVER R, CHERUKURI H P, et al. A realistic full-scale 3D modeling of turning using coupled smoothed particle hydrodynamics and finite element method for predicting cutting forces[J]. Journal of Manufacturing and Materials Processing, 2022, 6(2): 33. doi: 10.3390/jmmp6020033 [22] CHENG Y, LI Y, TAO L, et al. An adaptive smoothed particle hydrodynamics for metal cutting simulation[J]. Acta Mechanica Sinica, 2022, 38(10): 422126. doi: 10.1007/s10409-022-22126-x [23] KILUNDU B, DEHOMBREUX P, CHIEMENTIN X. Tool wear monitoring by machine learning techniques and singular spectrum analysis[J]. Mechanical Systems and Signal Processing, 2011, 25(1): 400-415. doi: 10.1016/j.ymssp.2010.07.014 [24] 陶耀东, 曾广圣, 李宁. 基于回归树和AdaBoost方法的刀具磨损评估[J]. 计算机系统应用, 2017, 26(12): 212-219.TAO Yaodong, ZENG Guangsheng, LI Ning. Tool wear evaluation based on decision tree regression and AdaBoost algorithm[J]. Computer Systems & Applications, 2017, 26(12): 212-219. (in Chinese) [25] SANJAY C, ALSAMHAN M A K A M. Experimental analysis of machining parameter for 625 alloy using multi objective genetic algorithm and machine learning techniques[J]. Journal of the Balkan Tribological Association, 2021, 27(6): 1040-1059. [26] SIMA M, TUĞRUL Ö. Modified material constitutive models for serrated chip formation simulations and experimental validation in machining of titanium alloy Ti-6Al-4V[J]. International Journal of Machine Tools and Manufacture, 2010, 50(11): 943-960. doi: 10.1016/j.ijmachtools.2010.08.004 [27] LUCY L B. A numerical approach to the testing of the fission hypothesis[J]. The Astronomical Journal, 1977, 82:1013. doi: 10.1086/112164 [28] GINGOLD R A, MONAGHAN J J. Monthly notices of the royal astronomical society[J]. Monthly Notices of the Royal Astronomical Society, 1977, 181(3): 375-389. doi: 10.1093/mnras/181.3.375 [29] LIU M B, LIU G R. Smoothed particle hydrodynamics (SPH): an overview and Recent developments[J]. Archives of Computational Methods in Engineering, 2010, 17(1): 25-76. doi: 10.1007/s11831-010-9040-7 [30] LI G, BELYTSCHKO T. Element-free Galerkin method for contact problems in metal forming analysis[J]. Engineering Computations, 2001, 18(1/2): 62-78. [31] TAYLOR G I, QUINNEY H. The latent energy remaining in a metal after cold working[J]. Proceedings of the Royal Society of London (Series A): Containing Papers of a Mathematical and Physical Character, 1934, 143(849): 307-326. [32] MONAGHAN J J. On the problem of penetration in particle methods[J]. Journal of Computational Physics, 1989, 82(1): 1-15. [33] BREIMAN L. Classification and Regression Trees[M]. 1st ed. Routledge, 1984. [34] 魏贞原. 机器学习[M]. 北京: 电子工业出版社, 2018: 229.WEI Zhenyuan. Machine Learning[M]. Beijing: Publishing House of Electronics Industry, 2018: 229. (in Chinese) [35] HASTIE T, TIBSHIRANI R, FRIEDMAN J H. The Elements of Statistical Learning: Data Mining, Inference, and Prediction[M]. 2nd ed. New York: Springer, 2009. [36] PATRO S G K, SAHU K K. Normalization: a preprocessing stage[J]. International Advanced Research Journal in Science, Engineering and Technology, 2015, 2(3): 20-22. DOI: 10.17148/IARJSET.2015.2305. -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号