Deformation Behavior Modeling of SMAs Under Cyclic Loading Based on Rational Interpolation

-

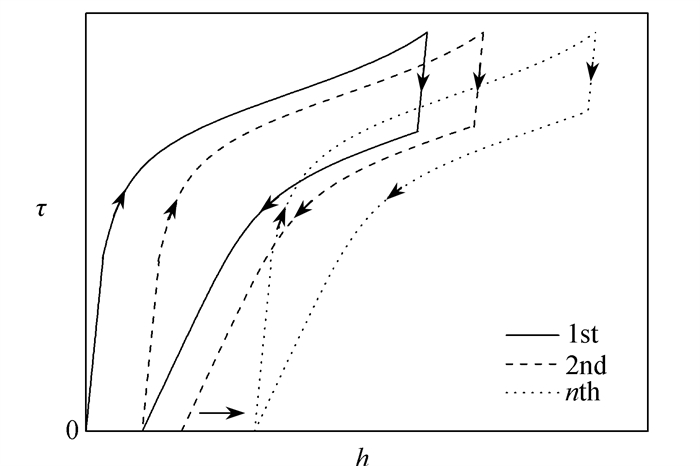

摘要: 提出了一个有限弹塑性模型,用来模拟形状记忆合金(shape memory alloys, SMAs)在循环荷载下的变形行为. 首先,通过分析上下屈服阶段形函数的特点,利用有理插值方法给出循环荷载下的应力-应变形函数显式表达, 可以精确匹配任意形状的实验数据;其次,基于对数客观率,构建了有限弹塑性J2流模型,耦合了屈服中心的移动和屈服面的增大;再次,从单轴情况出发,推导得到了单个循环下的三个硬化函数显式表达,再引入局部因子和多轴扩展不变量,构造了光滑统一且多轴有效的硬化函数;最后,将模型得到的结果与经典实验结果比较,证明了新方法的有效性. 该文创新点如下:第一,通过改进传统的背应力演化方程,使得新模型产生强烈的Bauschinger效应,从而使新方法具备模拟SMAs特殊变形行为的能力;第二,新的光滑统一硬化函数在单个循环下会自动退化,得到精确符合实验数据的结果;第三,利用本构方程推导得到有效塑性功演化规律,而有理插值得到的形函数中包含依赖有效塑性功的参数,给出这些参数方程以后使得模型具备了预测变形的能力.Abstract: A finite elastoplasticity model was proposed to simulate deformation behaviors of SMAs under cyclic loading. First, the explicit formulations of shape functions were given with the rational interpolation method to exactly match any given experimental data. Second, a finite elastoplasticity J2 flow model based on the logarithmic objective rate was built to couple the moving of the yielding center and the expanding of the yielding surface. Third, 3 explicit hardening functions under the single loading cycle were deduced in the uniaxial case, to construct the smooth, unified and multiaxial hardening function through introduction of the local factor and the multiaxial extended invariant. Finally, the model results were compared with the classical test data to prove the effectiveness of the new model. The research results show that, the new model can produce intense Bauschinger effects and simulate the complex deformation of SMAs through improvement of the evolution equation of the back stress. The new smooth unified hardening function can automatically degenerate under the single loading cycle to give results exactly matching the test data. The effective plastic work evolution law deduced with the constitutional equation, and the parameter equations dependent on the effective plastic work contained in the shape functions through rational interpolation, enable the proposed model to predict deformations well.

-

Key words:

- J2 flow model /

- SMAs /

- logarithmic objective rate /

- yielding /

- hardening function /

- shape function

-

表 1 形函数中关键点应力、应变和有效塑性功

Table 1. Stresses, strains and effective plastic works of key points in the shape function

points τ h $ \vartheta$ P0 0 hi-1p $ \vartheta$i-1 P1 r0 h0i $ \vartheta$i-1 P2 τi* hi* $ \vartheta$* Q1 τi* hi* $ \vartheta$i* Q2 0 hip $ \vartheta$i 表 2 pi(τ)中固定参数值

Table 2. Values of fixed parameters in pi(τ)

ξ1 ξ2 β1 r0/MPa 0.001 9 0 0.016 240 -

[1] LEAL P B C, SAVI M A. Shape memory alloy-based mechanism for aeronautical application: theory, optimization and experiment[J]. Aerospace Science and Technology, 2018, 76(4): 155-163. [2] CHENG C, CHENG J, HUANG W. Design anddevelopment of a novel SMA actuated multi-DOF soft robot[J]. IEEE Access, 2019, 7: 75073-75080. doi: 10.1109/ACCESS.2019.2920632 [3] WANG R, ZUO H, YANG Y M, et al. Finite element simulation and optimization of radial resistive force for shape memory alloy vertebral body stent[J]. Journal of Intelligent Material Systems and Structures, 2017, 28: 2140-2150. doi: 10.1177/1045389X16685442 [4] LAGOUDAS D C, EENCHEV P B, POPOV P, et al. Shape memory alloys, part Ⅱ: modeling of polycrystals[J]. Mechanics of Materials, 2006, 38(5/6): 430-462. [5] KHANDELWAL A, BURAVALLA V. Models for shape memory alloy behavior: an overview of modeling approaches[J]. The International Journal of Structural Changes in Solids, 2009, 1(1): 111-148. [6] LEXCELLENT C. Shape-Memory Alloys Handbook[M]. John Wiley & Sons, 2013. [7] CISSE C, ZAKI W, ZINEB T B. A review of constitutive models and modeling techniques for shape memory alloys[J]. International Journal of Plasticity, 2016, 76: 244-284. doi: 10.1016/j.ijplas.2015.08.006 [8] CISSE C, ZAKI W, ZINEB T B. A review of modeling techniques for advanced effects in shape memory alloy behavior[J]. Smart Materials and Structures, 2016, 25(10): 103001. doi: 10.1088/0964-1726/25/10/103001 [9] 杨建楠, 黄彬, 谷小军, 等. 形状记忆合金力学行为与应用[J]. 固体力学学报, 2021, 42(4): 345-375. doi: 10.19636/j.cnki.cjsm42-1250/o3.2021.028YANG Jiannan, HUANG Bin, GU Xiaojun, et al. Mechanical behavior and application of shape memory alloy[J]. Chinese Journal of Solid Mechanics, 2021, 42(4): 345-375. (in Chinese) doi: 10.19636/j.cnki.cjsm42-1250/o3.2021.028 [10] FALK F. Model free energy, mechanics, and thermo-dynamics of shape memory alloys[J]. Acta Metallurgica, 1980, 28(12): 1773-1780. doi: 10.1016/0001-6160(80)90030-9 [11] FALK F. Ginzburg-Landau theory of static domain in walls in shape-memory alloys[J]. Zeitschrift für Physik B: Condensed Matter, 1983, 51(2): 177-185. doi: 10.1007/BF01308772 [12] 曹艳华, 张姊同, 李楠. 时空多项式配点法求解三维Burgers方程[J]. 应用数学和力学, 2022, 43(9): 1045-1052. doi: 10.21656/1000-0887.420282CAO Yanhua, ZHANG Zitong, LI Nan. A space-time polynomial collocation method for solving 3D Burgers equations[J]. Applied Mathematics and Mechanics, 2022, 43(9): 1045-1052. (in Chinese) doi: 10.21656/1000-0887.420282 [13] DAW M S, BASKES M I. Embedded-atom method: derivation and application to impurities, surfaces, and other defects in metals[J]. Physical Review B, 1984, 29(12): 6443. doi: 10.1103/PhysRevB.29.6443 [14] WANG X M, XU B X, YUE Z F. Micromechanical modelling of the effect of plastic deformation on the mechanical behaviour in pseudoelastic shape memory alloys[J]. International Journal of Plasticity, 2008, 24(8): 1307-1332. doi: 10.1016/j.ijplas.2007.09.006 [15] 陶泽, 李墨筱, 提飞, 等. 充液弹性毛细管低温相变的力学分析[J]. 应用数学和力学, 2021, 42(10): 1045-1061. doi: 10.21656/1000-0887.420301TAO Ze, LI Moxiao, TI Fei, et al. Mechanics of low-temperature phase transition in liquid-filled elastic capillary tube[J]. Applied Mathematics and Mechanics, 2021, 42(10): 1045-1061. (in Chinese) doi: 10.21656/1000-0887.420301 [16] 高伟业, 张赛, 张杰, 等. 含湿相变粗糙多孔材质的热质耦合分形研究[J]. 应用数学和力学, 2022, 43(5): 561-568. doi: 10.21656/1000-0887.420328GAO Weiye, ZHANG Sai, ZHANG Jie, et al. Thermo-mass coupling fractal study of wet phase-change rough porous materials[J]. Applied Mathematics and Mechanics, 2022, 43(5): 561-568. (in Chinese) doi: 10.21656/1000-0887.420328 [17] TAYLOR G I, QUINNEY H. The plastic distortion of metals[J]. Philosophical Transactions of the Royal Society of London (Series A): Containing Papers of a Mathematical or Physical Character, 1931, 230 (681/693): 323-362. [18] OSTWALD R, BARTEL T, MENZEL A. A Gibbs-energy-barrier-based computational micro-sphere model for the simulation of martensitic phase-transformations[J]. International of Journal for Numerical Methods in Engineering, 2014, 97(12): 851-877. doi: 10.1002/nme.4601 [19] TANAKA K. A thermomechanical sketch of shape memory effect: one-dimensional tensile behavior[J]. Res Mechanica, 1986, 18: 251-263. [20] BRINSON L C. One-dimensional constitutive behavior of shape memory alloys: thermomechanical derivation with non-constant material functions and redefined martensite internal variable[J]. Journal of Intelligent Material Systems and Structures, 1993, 4(2): 229-242. doi: 10.1177/1045389X9300400213 [21] LAGOUDAS D C, BO Z, QIDWAI M A. A unified thermodynamic constitutive model for SMA and finite element analysis of active metal matrix composites[J]. Mechanics of Composite Materials and Structures, 1996, 3(2): 153-179. doi: 10.1080/10759419608945861 [22] ZAKI W, MOUMNI Z. A 3D model of the cyclic thermomechanical behavior of shape memory alloys[J]. Journal of the Mechanics and Physics of Solids, 2007, 55: 2427-2454. doi: 10.1016/j.jmps.2007.03.011 [23] SHAW J A, KYRIAKIDES S. Thermomechanical aspects of NiTi[J]. Journal of the Mechanics and Physics of Solids, 1995, 43: 1243-1281. doi: 10.1016/0022-5096(95)00024-D [24] 曾忠敏, 彭向和. 计及相变与塑性的NiTi形状记忆合金循环伪弹性特性描述[J]. 应用数学和力学, 2014, 35(8): 850-862. doi: 10.3879/j.issn.1000-0887.2014.08.003ZENG Zhongmin, PENG Xianghe. A constitutive description of cyclic pseudoelasticity for the NiTi SMAs involving coupled phase transformation and plasticity[J]. Applied Mathematics and Mechanics, 2014, 35(8): 850-862. (in Chinese) doi: 10.3879/j.issn.1000-0887.2014.08.003 [25] MIYAZAKI S, IMAI T, IGO Y, et al. Effect of cyclic deformation on the pseudoelasticity characteristics of Ti-Ni alloys[J]. Metallurgical Transactions A, 1995, 17: 115-120. [26] KANG, G. Advances in transformation ratcheting and ratcheting-fatigue interaction of NiTi shape memory alloy[J]. Acta Mechanica Solida Sinica, 2013, 26: 221-236. doi: 10.1016/S0894-9166(13)60021-X [27] AURICCHIO F, TAYLOR R L, LUBLINER J. Shape-memory alloys: macro-modelling and numerical simulations of the superelastic behavior[J]. Computer Methods in Applied Mechanics and Engineering, 1997, 146(3/4): 281-312. [28] BO Z, LAGOUDAS D C. Thermomechanical modeling of polycrystalline SMAs under cyclic loading, part Ⅰ: theoretical derivations[J]. International Journal of Engineering Science, 1999, 37(9): 1089-1140. doi: 10.1016/S0020-7225(98)00113-X [29] BO Z, LAGOUDAS D C. Thermomechanical modeling of polycrystalline SMAs under cyclic loading, part Ⅲ: evolution of plastic strains and two-way shape memory effect[J]. International Journal of Engineering Science, 1999, 37(9): 1175-1203. doi: 10.1016/S0020-7225(98)00115-3 [30] BO Z, LAGOUDAS D C. Thermomechanical modeling of polycrystalline SMAs under cyclic loading, part Ⅳ: modeling of minor hysteresis loops[J]. International Journal of Engineering Science, 1999, 37(9): 1205-1249. doi: 10.1016/S0020-7225(98)00116-5 [31] AURICCHIO F, MARFIA S, SACCO E. Modelling of SMA materials: training and two-way memory effects[J]. Computers & Structures, 2003, 81(24/25): 2301-2317. [32] AURICCHIO F, REALI A, STEFANELLI U. A three-dimensional model describing stress-induced solid phase transformation with permanent inelasticity[J]. International Journal of Plasticity, 2007, 23(2): 207-226. doi: 10.1016/j.ijplas.2006.02.012 [33] ZAKI W, MOUMNI Z. A three-dimensional model of the thermomechanical behavior of shape memory alloys[J]. Journal of the Mechanics and Physics of Solids, 2007, 55(11): 2455-2490. doi: 10.1016/j.jmps.2007.03.012 [34] PATOOR E, EBERHARDT A, BERVEILLER M. Micromechanical modelling of superelasticity in shape memory alloys[J]. Le Journal de Physique, 1996, 6: 277-292. [35] PATOOR E, LAGOUDAS D C, ENTCHEV P B, et al. Shape memory alloys, part Ⅰ: general properties and modeling of single crystals[J]. Mechanics of Materials, 2006, 38(5/6): 391-429. [36] HUANG M, GAO X, BRINSON L C. A multivariant micromechanical model for SMAs part 2: polycrystal model[J]. International Journal of Plasticity, 2000, 16(10/11): 1371-1390. [37] LAGOUDAS D C, ENTCHEV P B. Modeling of transformation-induced plasticity and its effect on the behavior of porous shape memory alloys, part Ⅰ: constitutive model for fully dense SMAs[J]. Mechanics of Materials, 2004, 36(9): 865-892. doi: 10.1016/j.mechmat.2003.08.006 [38] KANG G, KAN Q, QIAN L, et al. Ratchetting deformation of superelastic and shape-memory NiTi alloys[J]. Mechanics of Materials, 2009, 41(2): 139-153. doi: 10.1016/j.mechmat.2008.09.001 [39] YU C, KANG G, KAN Q, et al. A micromechanical constitutive model based on crystal plasticity for thermo-mechanical cyclic deformation of NiTi shape memory alloys[J]. International Journal of Plasticity, 2013, 44: 161-191. doi: 10.1016/j.ijplas.2013.01.001 [40] YU C, KANG G, SONG D, et al. Effect of martensite reorientation and reorientation-induced plasticity on multiaxial transformation ratchetting of super-elastic NiTi shape memory alloy: new consideration in constitutive model[J]. International Journal of Plasticity, 2015, 67: 69-101. doi: 10.1016/j.ijplas.2014.10.001 [41] XIAO H. Pseudo-elastic hysteresis out of recoverable finite elastoplastic flows[J]. International Journal of Plasticity, 2013, 41: 82-96. doi: 10.1016/j.ijplas.2012.09.003 [42] WANG X M, WANG Z L, XIAO H. SMA pseudo-elastic hysteresis with tension-compression asymmetry: explicit simulation based on elasticity models[J]. Continuum Mechanics and Thermodynamics, 2015, 427: 959-970. [43] 王晓明, 吴荣兴, 肖衡. 显式模拟类橡胶材料Mullins效应滞回圈[J]. 力学学报, 2019, 51(2): 484-493. https://www.cnki.com.cn/Article/CJFDTOTAL-LXXB201902019.htmWANG Xiaoming, WU Rongxing, XIAO Heng. Explicit modeling the hysteresis loops of the Mullins effect for rubber-like material[J]. Chinese Journal of Theoretical and Applied Mechanics, 2019, 51(2): 484-493. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-LXXB201902019.htm [44] 王晓明, 郑东, 吴荣兴, 等. 类橡胶材料变形直到破坏的显式本构模型[J]. 力学季刊, 2019, 40(2): 252-264. https://www.cnki.com.cn/Article/CJFDTOTAL-SHLX201902004.htmWANG Xiaoming, ZHENG Dong, WU Rongxing, et al. Explicit constitutive model of rubber-like materials up to failure[J]. Chinses Quarterly of Mechanics, 2019, 40(2): 252-264. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-SHLX201902004.htm [45] 王晓明, 肖衡. 显式方法精确模拟形状记忆聚合物热力学行为[J]. 固体力学学报, 2020, 41(4): 366-378. https://www.cnki.com.cn/Article/CJFDTOTAL-GTLX202004006.htmWANG Xiaoming, XIAO Heng. Accurately modeling thermomechancial behavior of shape memory polymer with explicit method[J]. Chinese Journal of Solid Mechanics, 2020, 41(4): 366-378. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GTLX202004006.htm [46] 王晓明, 吴荣兴, 蒋义, 等. 显式模拟类橡胶材料应力软化引起的不可恢复变形及其各向异性特征[J]. 力学学报, 2021, 53(7): 1999-2009. https://www.cnki.com.cn/Article/CJFDTOTAL-LXXB202107017.htmWANG Xiaoming, WU Rongxing, JIANG Yi, et al. Explicitly modeling permanent set and anisotropy property induced by stress softening for rubber-like materials[J]. Chinese Journal of Theoretical and Applied Mechanics, 2021, 53(7): 1999-2009. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-LXXB202107017.htm [47] 王晓明, 肖衡. 基于有限变形弹塑性模型模拟伪弹性合金全程变形行为[J]. 应用数学和力学, 2018, 39(3): 286-299. doi: 10.21656/1000-0887.380067WANG Xiaoming, XIAO Heng. Comprehensive simulation of shape memory alloys based on a finite elastoplastic model[J]. Applied Mathematics and Mechanics, 2018, 39(3): 286-299. (in Chinese) doi: 10.21656/1000-0887.380067 [48] XIAO H. An explicit, straightforward approach to modeling SMA pseudo-elastic hysteresis[J]. International Journal of Plasticity, 2014, 53: 228-240. [49] XIAO H, WANG X M, WANG Z L, et al. Explicit, comprehensive modeling of multi-axial finite strain pseudo-elastic SMAs up to failure[J]. International Journal of Solids and Structures, 2016, 88/89 : 215-226. [50] ZHAN L, WANG X M, WANG S Y, et al. An explicit and accurate approach toward simulating plastic-to-pseudoelastic transitions of SMAs under multiple loading and unloading cycles[J]. International Journal of Solids and Structures, 2020, 185: 104-115. [51] XIAO H, BRUHNS O T, MEYERS A. Elastoplasticity beyond small deformations[J]. Acta Mechanica, 2006, 182: 31-111. [52] XIAO H, BRUHNS O T, MEYERS A. Logarithmic strain, logarithmic spin and logarithmic rate[J]. Acta Mechanica, 1997, 124: 89-105. [53] BRUHNS O T, XIAO H, MEYERS A. Some basic issues in traditional Eulerian formulations of finite elastoplasticity[J]. International Journal of Plasticity, 2003, 19: 2007-2026. -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号